An integrated process for low-temperature flue gas desulfurization, denitrification and ammonia removal

A technology for desulfurization, denitrification, and low-temperature flue gas, which is applied in chemical instruments and methods, dispersed particle separation, separation methods, etc., can solve the problems of increasing one-time investment and operating costs, no coke oven flue gas denitrification, and technical disclosure information, etc. Achieve the effect of improving ammonia removal efficiency and denitration efficiency, reducing operating cost and one-time investment, and reducing concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

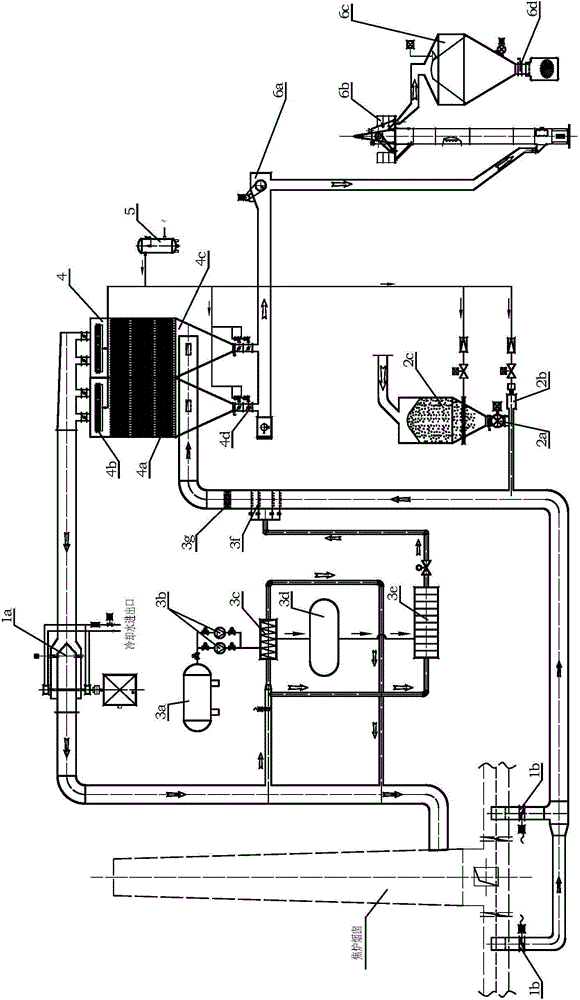

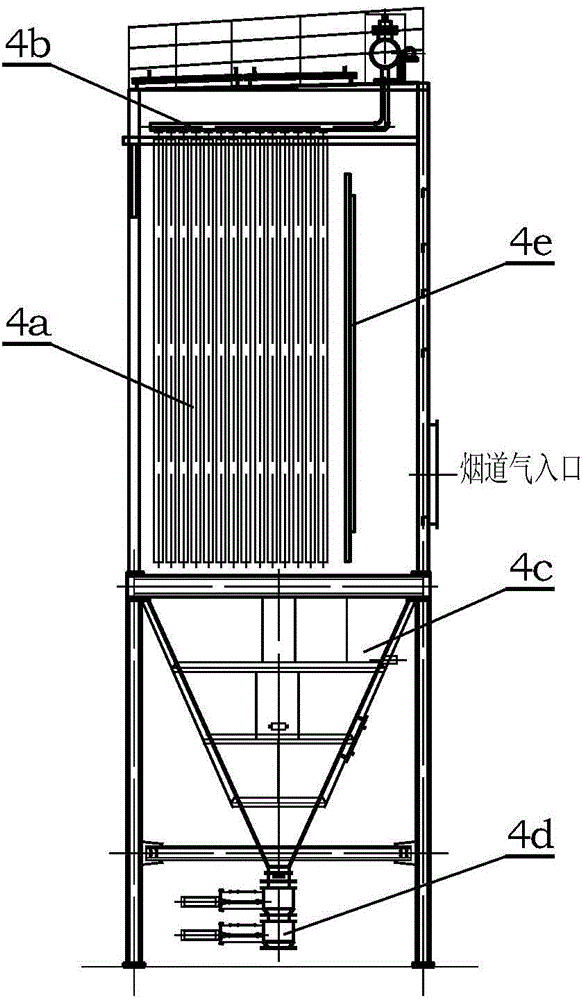

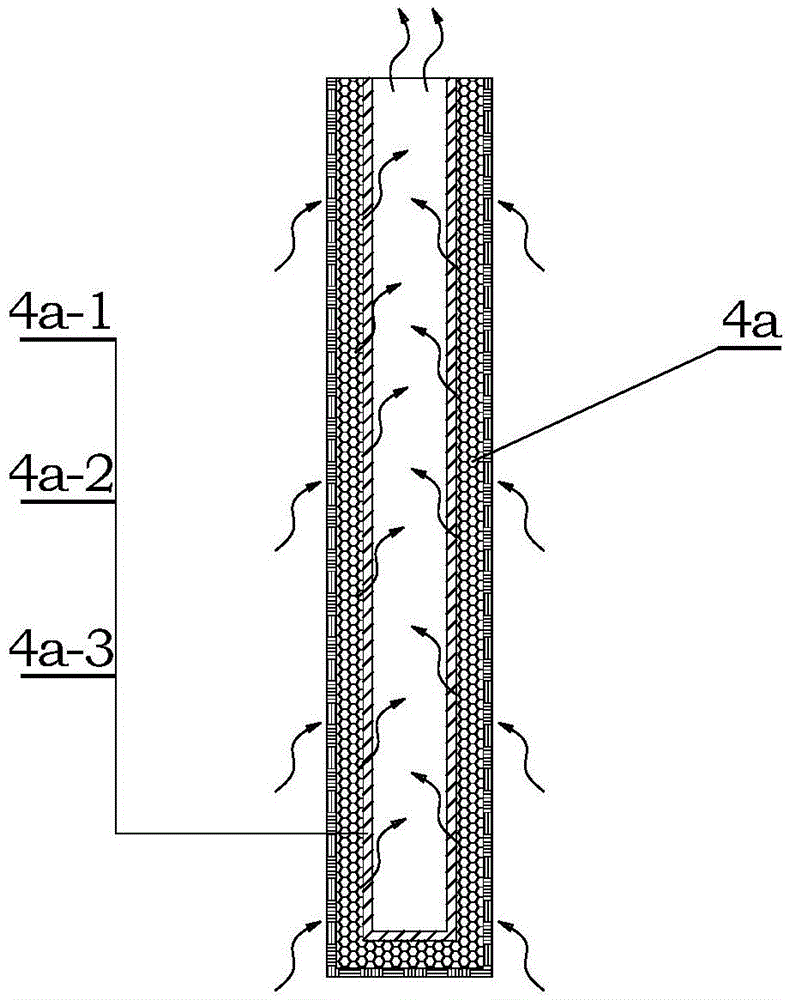

[0042] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0043] See figure 1 , is a process schematic diagram of a low-temperature flue gas desulfurization, denitrification and ammonia removal integrated process of the present invention. Starting from the coke oven chimney, along the flue gas flow direction, the flue gas main pipe is sequentially provided with a fluidized desulfurization agent injection inlet, a spray Ammonia grid 3f; static mixer 3g, ammonia removal and denitrification equipment 4, induced draft fan 1a, flue gas inlet and outlet for ammonia preparation and mixing, and a flue gas inlet air volume regulating valve 1b is installed on the flue gas conveying pipe at the root of the chimney.

[0044] The injection port of the fluidized desulfurization agent is connected to the dry powder fluidization equipment 2b. Above the dry powder fluidization equipment 2b is the dry powder storage tank ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com