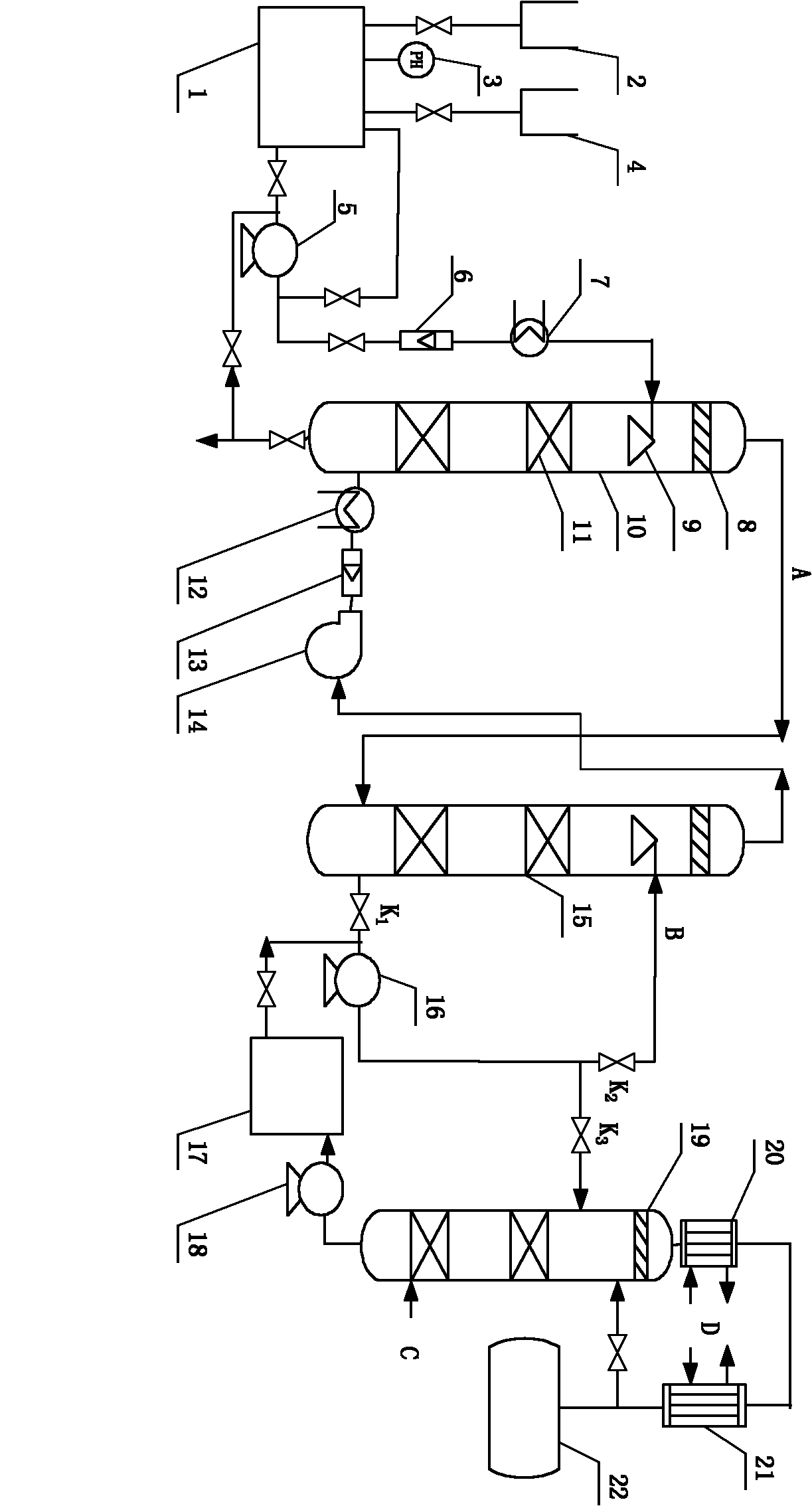

Closed-loop processing integrated process for high-efficiency air stripping and tail-gas ammonia recycling of ammonia-nitrogen wastewater

A technology of ammonia nitrogen wastewater and resource utilization, applied in degassed water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problem of ammonia nitrogen wastewater treatment, which is difficult to meet the standard discharge total control and resource utilization Low degree, high operating cost and other problems, to achieve the effect of improving ammonia removal efficiency, reducing gas-liquid volume ratio, and significant economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The composition and concentration of high-concentration ammonia-nitrogen wastewater produced during the production process of a coking plant are: NH 3 -N, 8000~20000mg / L, pH 4~7, utilize the present invention to carry out the pretreatment steps as follows:

[0028] 1) Send the coking wastewater into the adjustment tank, add KOH to adjust the pH value to 10, and add sodium lauryl sulfate at the same time, the addition amount is 20ppm, and then preheat to 60°C with the heater;

[0029] 2) The pretreated wastewater enters the upper part of the stripping tower with corrugated wire mesh packing, and is evenly distributed on the packing by a spray distributor, and is blown off at a gas-liquid volume ratio of 1500:1, and the blown off tail gas enters the absorption through the demister Tower, the concentration of ammonia nitrogen at the bottom of the tower after first-stage stripping is 200mg / L;

[0030] 3) Ammonia-containing stripping tail gas enters the bottom of the absorp...

Embodiment 2

[0033] A chemical catalyst (V 2 o 5 ) factory wastewater, the composition and concentration are: NH 3 -N, 2000~6000mg / L, pH 7~8, using the present invention to carry out standard discharge treatment steps are as follows:

[0034] 1) Send the catalyst waste water into the adjustment tank, add NaOH to adjust the pH value to 11, and add dodecyltrimethylammonium bromide at the same time, the addition amount is 20ppm, and then preheat to 50°C through the heater;

[0035]2) The pretreated wastewater enters the blow-off tower with PVC inclined tube packing, and is evenly distributed on the packing through the orifice flow disc distributor, and blows off at a gas-liquid volume ratio of 1250:1. The ammonia nitrogen concentration of the bottom wastewater is 200mg / L; the bottom wastewater is sent to the stripping tower for secondary stripping through the feed pump, and the ammonia nitrogen concentration of the tower bottom wastewater is 15mg / L to meet the standard discharge; the stripp...

Embodiment 3

[0039] The composition and concentration of waste water from an amino acid production plant are: NH 3 -N, 800~2000mg / L, pH 3~5, utilize the present invention to carry out pretreatment steps as follows:

[0040] 1) Send the amino acid production wastewater into the adjustment tank, add KOH to adjust the pH value to 11.5, and add sodium dodecylbenzenesulfonate at the same time, the addition amount is 20ppm, and then preheat to 40°C through the heater;

[0041] 2) The pretreated wastewater enters the Pall ring packing blow-off tower, and is evenly distributed on the packing through the overflow tank distributor, blows off at a gas-liquid volume ratio of 1000:1, and the blow-off tail gas enters through the demister Absorption tower, the concentration of ammonia nitrogen at the bottom of the tower is 190mg / L after first-stage stripping;

[0042] 3) The tail gas containing ammonia is blown off into the bottom of the absorption tower, and the 35wt% acetic acid absorption solution sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com