Cyclone stripping integration ammonia removal reaction tower

A reaction tower, spiral atomization technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. The effect of low consumption and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

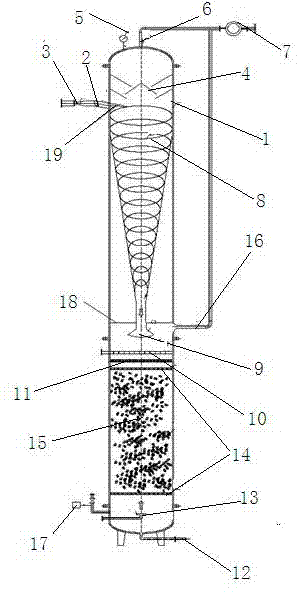

[0021] Example 1: Such as figure 1 Shown is a kind of integrated ammonia removal reaction tower with cyclone blowing off, the reaction tower is a sealed tank body 1 with integral structure, including input device, cyclone separation device, blowing device, detection device and output device; The flow separation device is arranged at the upper end of the tank body 1, and the blow-off device is arranged at the lower end of the tank body 1. The cyclone separation device and the blow-off device are separated by a baffle 18, and the bottom of the cyclone separation device is provided with a water distribution device to control the uniformity of the water outlet. device 9, and the water distributor 9 communicates with the blow-off device. The device has simple structure, convenient operation, low energy consumption and high blowing efficiency.

Embodiment 2

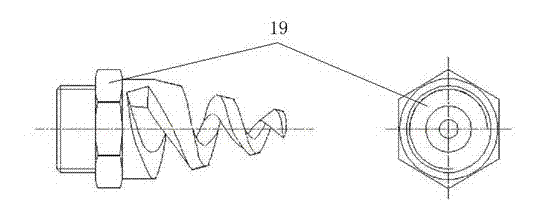

[0022] Example 2: Such as figure 1 , 2 As shown, the input device includes a Venturi tube 3, a water inlet pipe 2, a spiral atomizing nozzle 19 and an air inlet pipe 13, and one end of the water inlet pipe 13 is connected with a Venturi tube 3, and the other end is connected with a spiral atomizing nozzle 19, The spiral atomizing nozzle 19 is installed on the top of the cyclone separation device, and the air inlet pipe 13 is installed at the bottom of the blow-off device; the liquid inlet speed is increased through the Venturi tube 3, and the Venturi tube 3 and the atomizing nozzle 19 work together The lower control liquid enters the state of atomization. The rest of the structures and advantages are exactly the same as in Embodiment 1.

Embodiment 3

[0023] Example 3: Such as figure 1 As shown, the cyclone separation device includes a gas-liquid separator 4 and a diversion groove 8, the gas-liquid separator 4 is installed on the upper part of the spiral atomization nozzle 19, and the flow diversion groove 8 is arranged on the spiral atomization nozzle 19, the bottom of the diversion groove 8 is connected with a water distributor 9, and the diversion groove 8 is set as a conical spiral diversion groove, and the conical spiral diversion groove controls the water to fall in a spiral manner, thereby Prolong the gas-liquid separation time. The rest of the structures and advantages are exactly the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com