Desulfurization ammonia nitrogen wastewater processing method

A technology for ammonia nitrogen wastewater and wastewater, applied in the direction of degassed water/sewage treatment, gaseous effluent wastewater treatment, multi-stage water treatment, etc., can solve the problems of large steam consumption, difficult treatment, high equipment cost, etc., to reduce steam consumption amount, prevent secondary pollution, and reduce energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

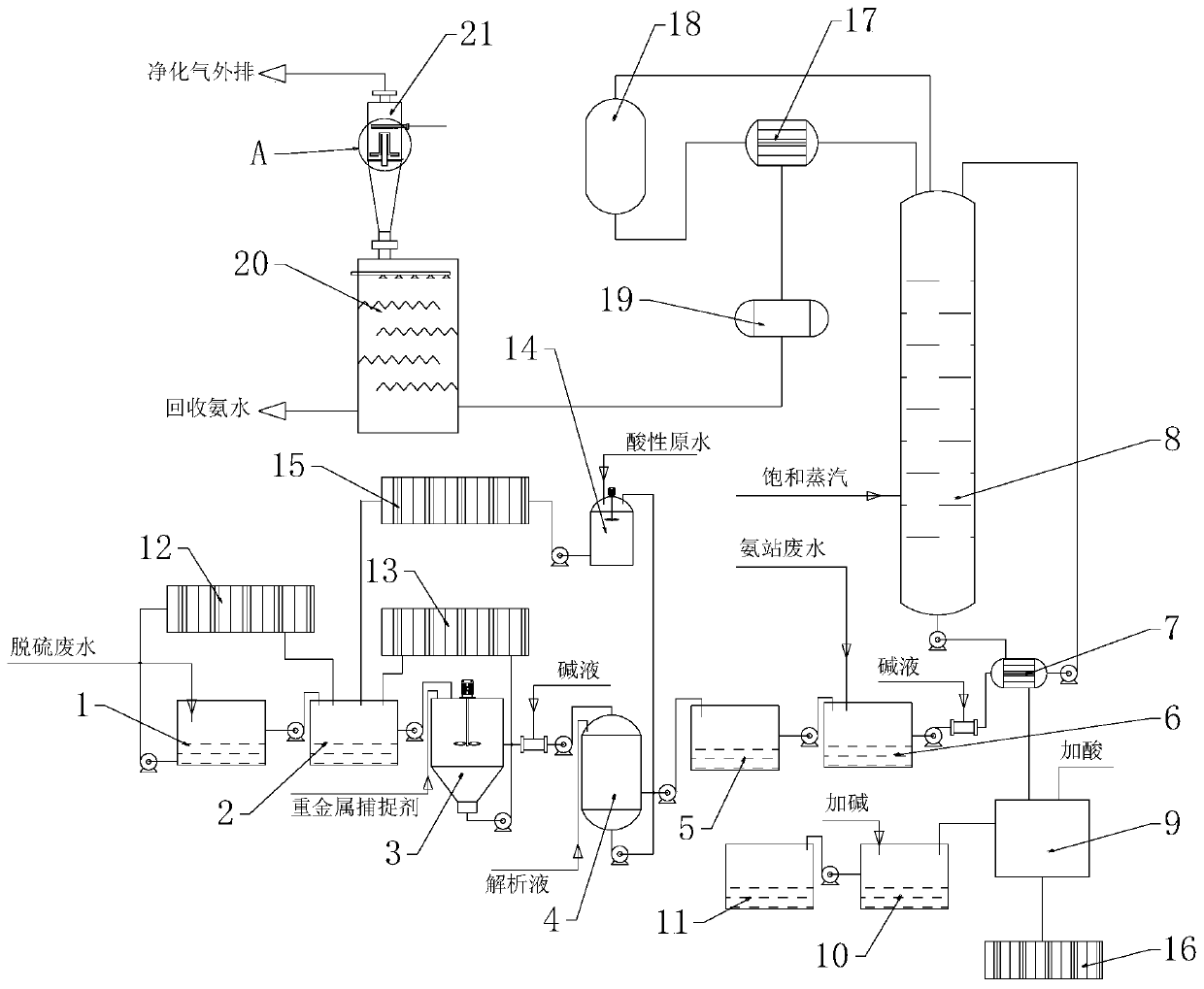

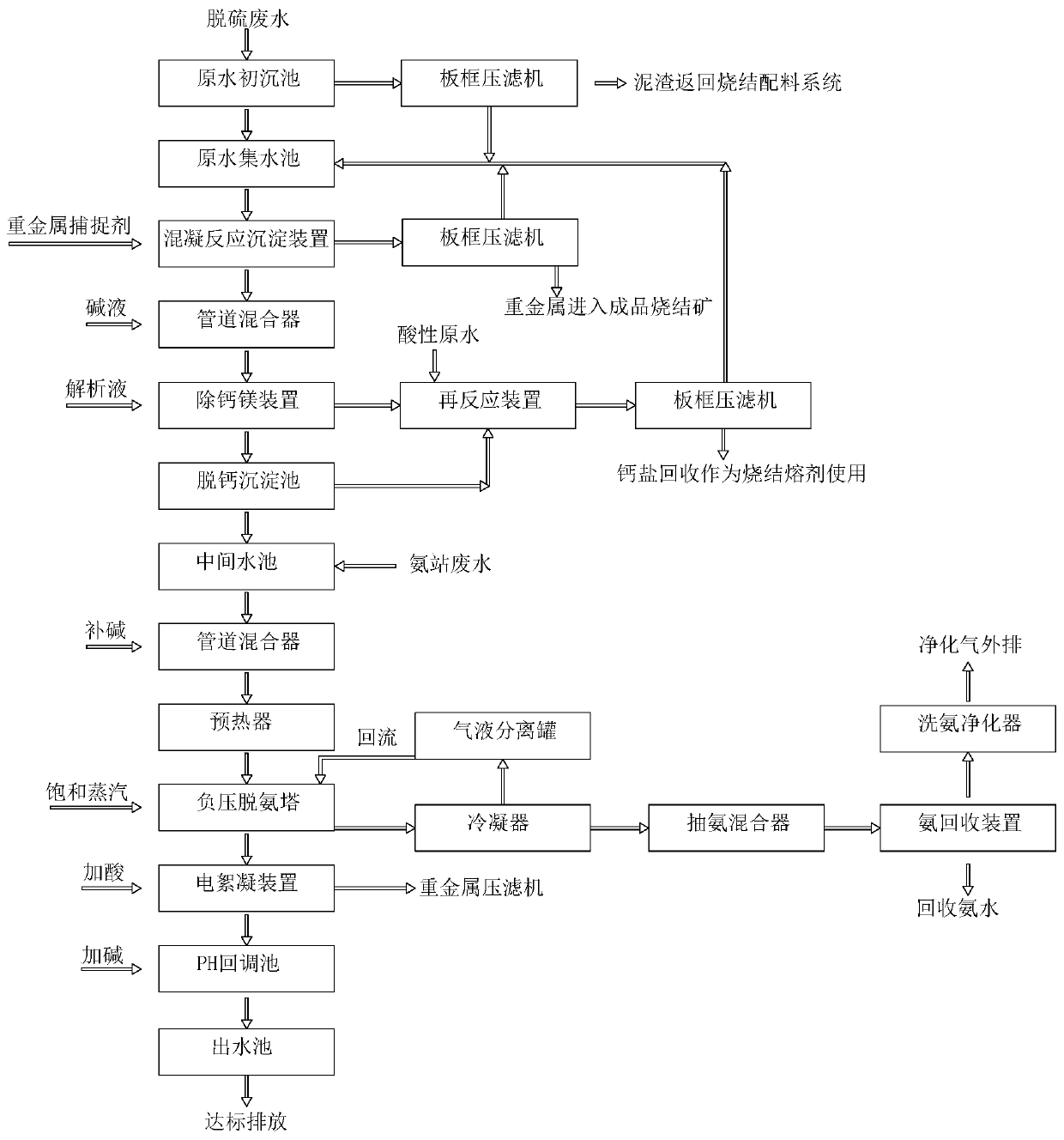

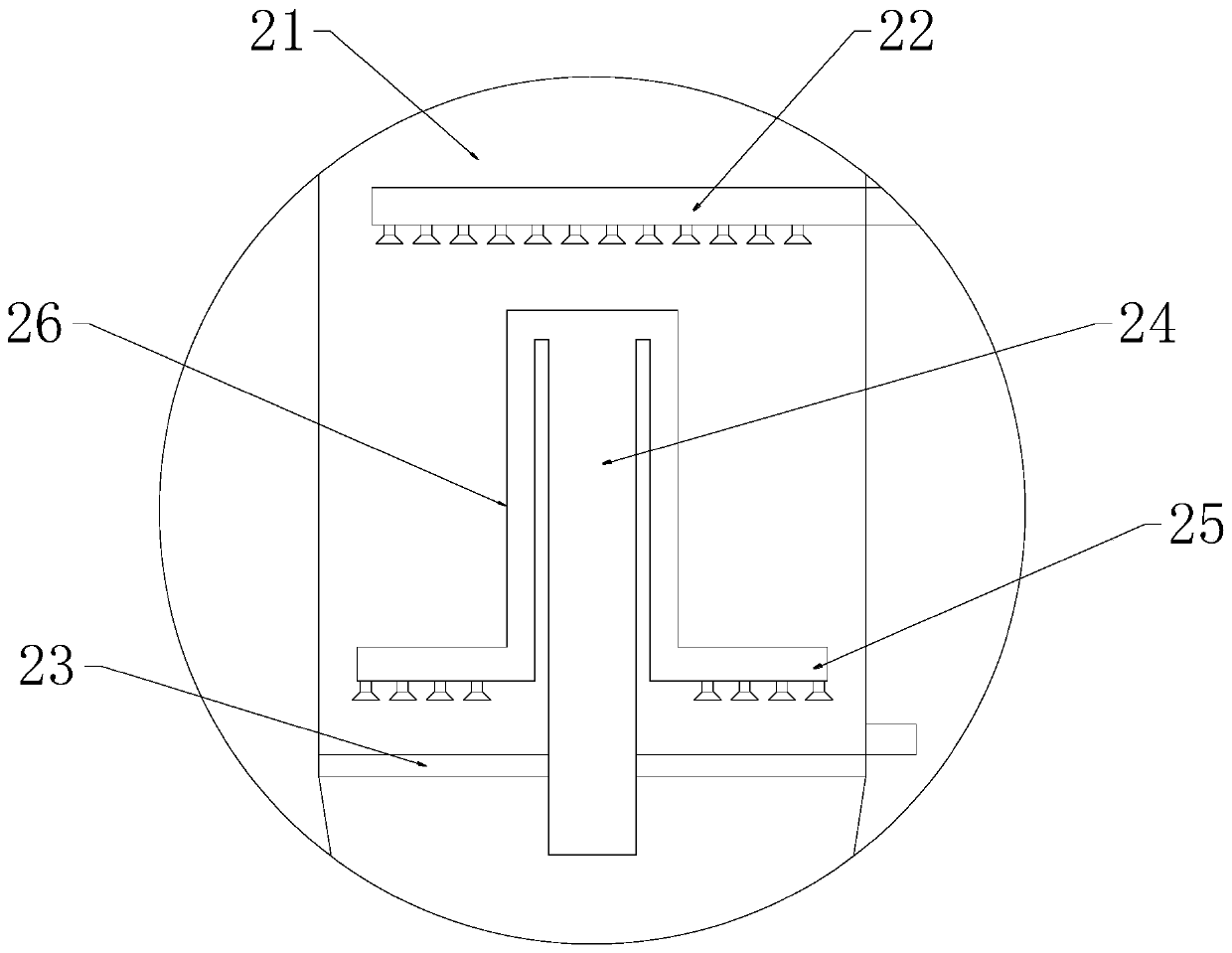

[0032] refer to figure 1 and image 3 , a desulfurization ammonia nitrogen wastewater treatment system device, including a raw water primary sedimentation tank 1 for wastewater precipitation, a coagulation reaction precipitation device 3 for precipitation and recovery of heavy metals, a calcium and magnesium removal device 4 for removing calcium and magnesium ions, Negative pressure deamination system for deamination, electrocoagulation device 9 for flocculation and removal of remaining heavy metals, and ammonia washing purifier 21 for tail gas treatment, ammonia washing purifier 21 is selected but not limited to WDJHT-2000 type, the washing A water distributor 22 is arranged inside the ammonia purifier 21, and a water seal structure 26 is arranged below the water distributor 22 of the ammonia washing purifier 21, and the water sealing structure 26 includes separating the ammonia washing purifier 21 into upper and lower parts. The baffle 23, the air intake pipe 24 penetrating...

Embodiment 2

[0046] In this embodiment, the ammonia nitrogen in the 125t / d total wastewater of a certain company is treated and recovered as an example. There are three streams of wastewater, one of which is sintered limestone-gypsum wet desulfurization wastewater, with a water volume of 5t / h, containing a large amount of calcium ions and Suspended solids; the other stream is dry desulfurization wastewater, that is, acidic raw water, with a water volume of 1.5t / h, containing a large amount of sulfuric acid and suspended solids; the third stream of wastewater is wastewater from the ammonia station system, with a water volume of 5t / d and an ammonia content of about 5%; The relevant parameters of the wastewater are shown in Table 1.

[0047] Table 1 Relevant parameters of ammonia nitrogen wastewater, treated water volume: 125t / d, calculated on the basis of 5.5t / h

[0048] Item (mg / L) Wet desulfurization wastewater Dry desulfurization wastewater Ammonia station system wastewate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com