Technology for treating high concentration ammonia nitrogen waste water using membrane based absorption method

An ammonia nitrogen wastewater, membrane-based absorption technology, applied in membrane technology, water/sewage treatment, neutralized water/sewage treatment, etc., can solve the problem of less engineering research and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

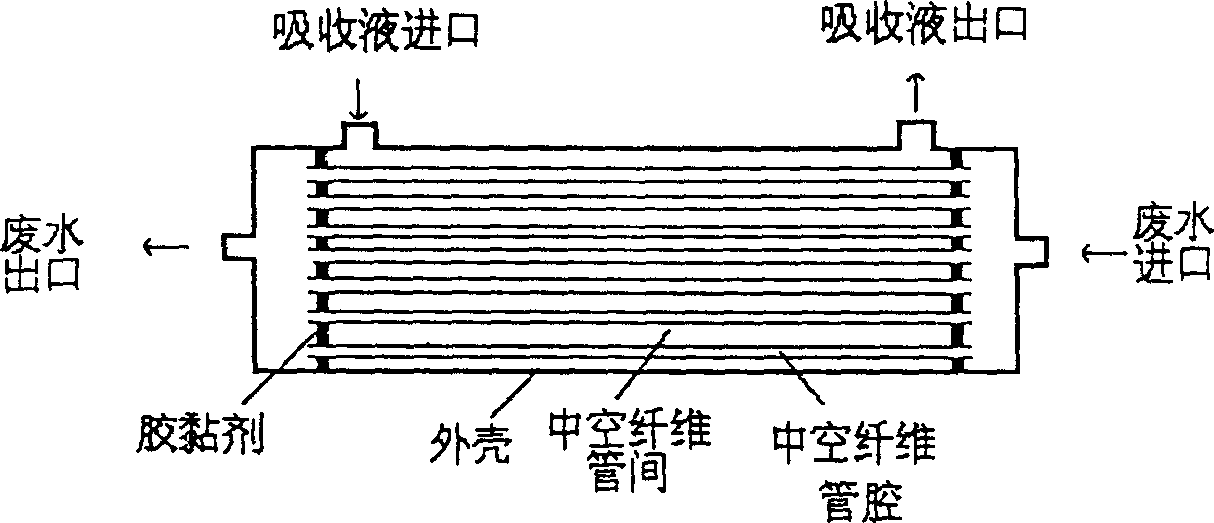

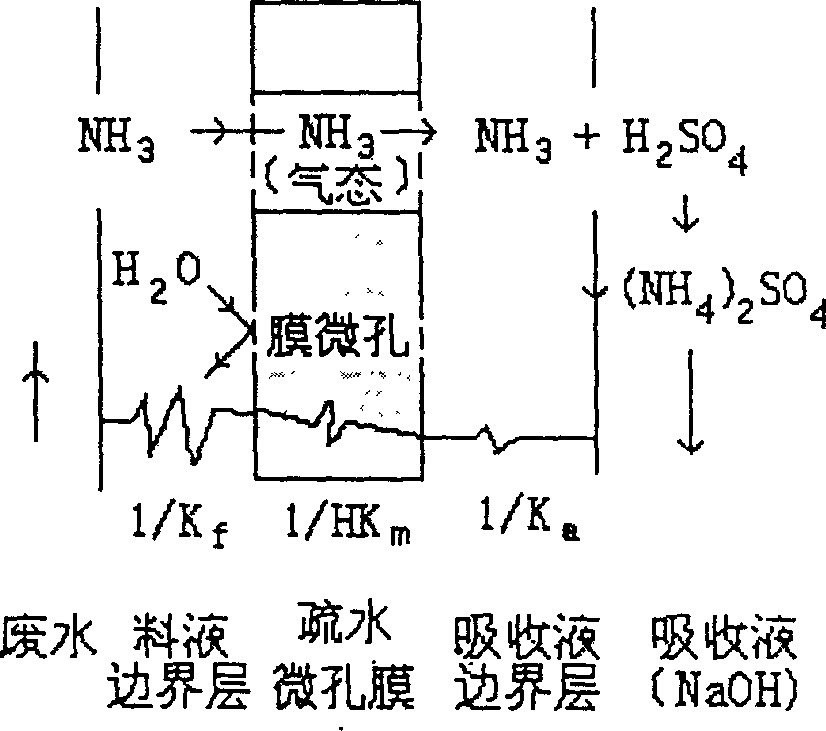

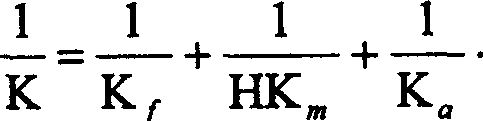

Method used

Image

Examples

Embodiment 1

[0057] The present invention is actually applied in a certain coking plant to treat "surplus ammonia water". A coking plant mainly produces coke and gas, and recovers tar, benzene, naphthalene and other chemical by-products. A large amount of wastewater is generated during the production process, among which the so-called "residual ammonia water" produced during the pyrolysis of coal and the cooling of raw gas is the main source of wastewater. The characteristics of the remaining ammonia water are: (1) the amount of water is large, accounting for more than half of the waste water in the whole plant; (2) the water quality is complex, and the components are various. In addition to inorganic pollutants such as ammonia, cyanide, and thiocyanate, it also contains phenol , oils, naphthalene, pyridine, quinoline, anthracene and other condensed ring aromatic compounds, etc. (3) The concentration of pollutants is high, among which NH 3 Up to 3000-5000mg / L, COD Cr The content is betwe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Removal rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com