Maleic anhydride tail gas treatment equipment and maleic anhydride tail gas treatment process

A tail gas treatment and maleic anhydride technology, applied in the field of maleic anhydride tail gas treatment process, can solve the problems of large deacidification tower equipment, corrosion protection, solvent loss, etc., to reduce equipment investment costs, reduce production costs, and reduce solvent consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and specific implementation examples.

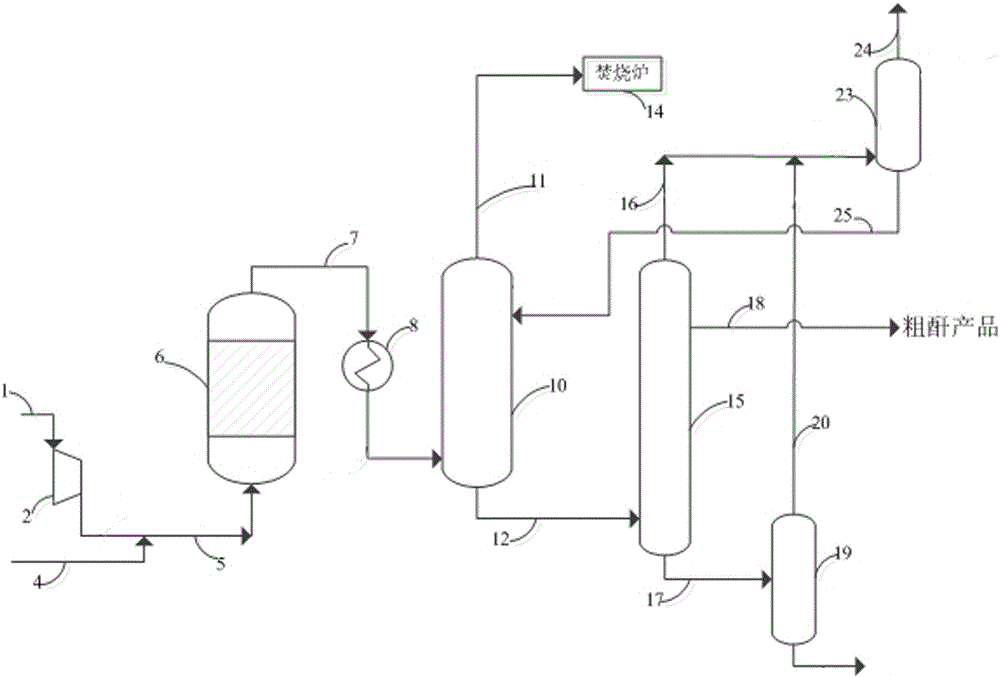

[0034] Implementation condition 1: with figure 1 For example, figure 1 It is a traditional process flow chart without tail gas circulation. Air 1 is mixed with n-butane 4 through air compressor 2; mixed raw material gas 5 enters maleic anhydride reactor 6 for reaction, and the reaction conditions are: 420°C, 0.19MPa, 1560h -1 The reaction gas 7 that comes out from maleic anhydride reactor 6 enters maleic anhydride absorption tower 10 through gas cooler 8 cooling, and product maleic anhydride is absorbed in reaction gas in maleic anhydride absorption tower 10, and maleic anhydride absorption tower tower top tail gas 11 sends To the incinerator 14, the rich liquid 12 at the bottom of the maleic anhydride absorption tower is sent to the maleic anhydride desorption tower 15 for desorption; the maleic anhydride desorption tower 15 side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com