Manual screw type self weight loading device for physical landslide model test

A landslide physical model and manual screw technology, applied in soil material testing, material inspection products, etc., can solve the problem of fast, stable, and continuous thrust loading requirements on the trailing edge of landslides, difficulty in accurately controlling the magnitude and direction of landslide thrust, and boundary conditions. Inconsistent conditions and other problems, to achieve the effect of easy movement and transportation, easy repair or replacement, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

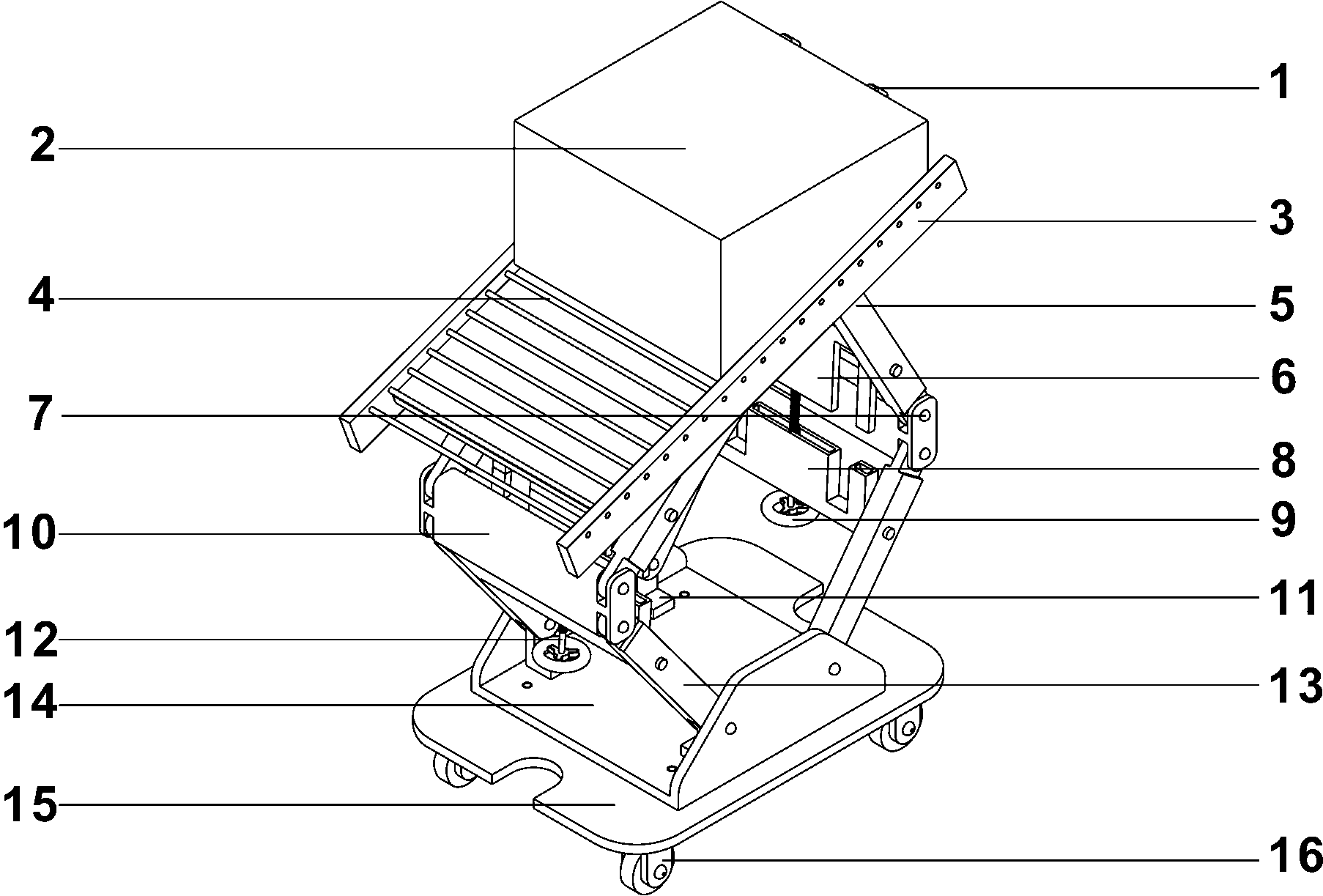

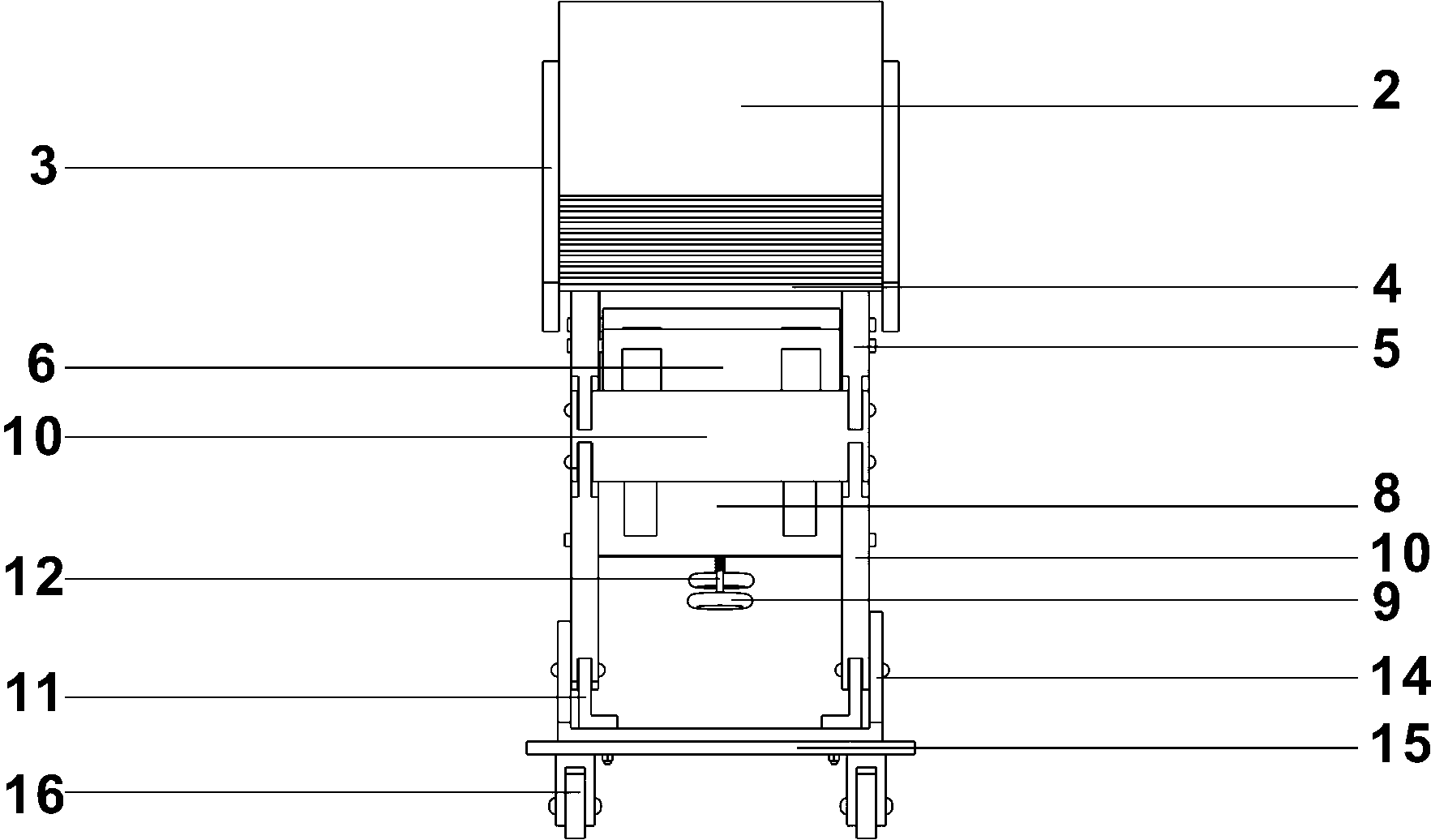

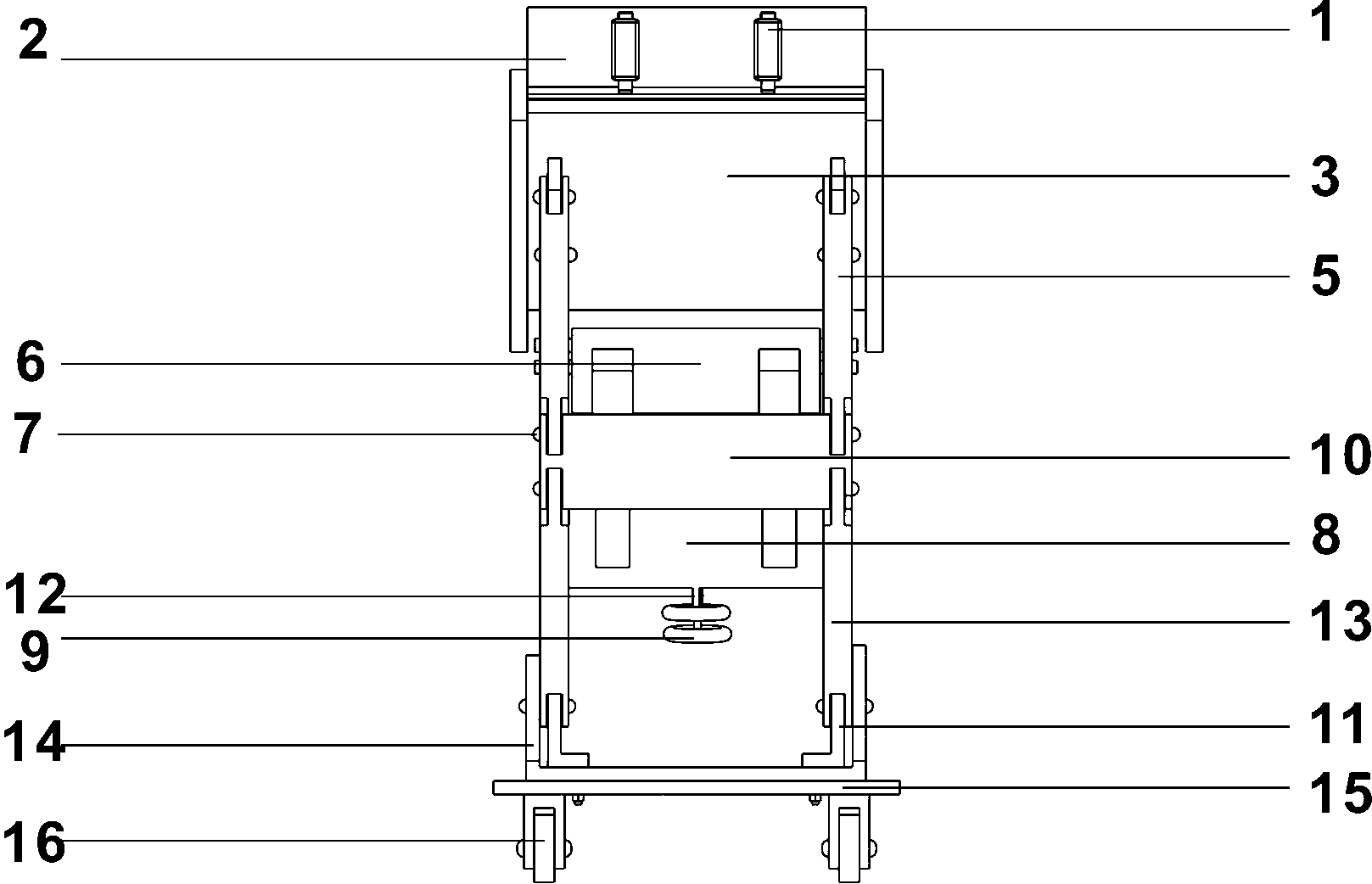

[0034] Specific embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0035] Such as Figure 1 to Figure 5 As shown, a manual screw-type self-weight loading device for a landslide physical model test of the present invention includes a bottom plate 15, a sliding surface adjustment mechanism and a thrust loading mechanism, specifically.

[0036] Base plate 15 below is provided with some walking wheels 16, so that the movement of whole device.

[0037] The sliding surface adjustment mechanism is located on the bottom plate 15. The sliding surface adjustment mechanism in this embodiment includes a sliding panel 3, an upper connecting rod 5, a lower connecting rod 13, a support plate 14, an insert block 6, a slot 8, a screw rod 12 and a hand wheel 9 . The support plate 14 is fixed on the base plate 15, and the front and rear portions of the support plate 14 are respectively hinged with the lower ends of a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com