Low-temperature heat insulation gas cylinder horizontal seal head assembly device

A low-temperature heat insulation and gas supply device technology, applied in auxiliary devices, household containers, applications, etc., can solve problems such as unfavorable product assembly line production, inconvenience for workers to operate, and restrict production efficiency, so as to facilitate assembly line production and save the number of operators , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

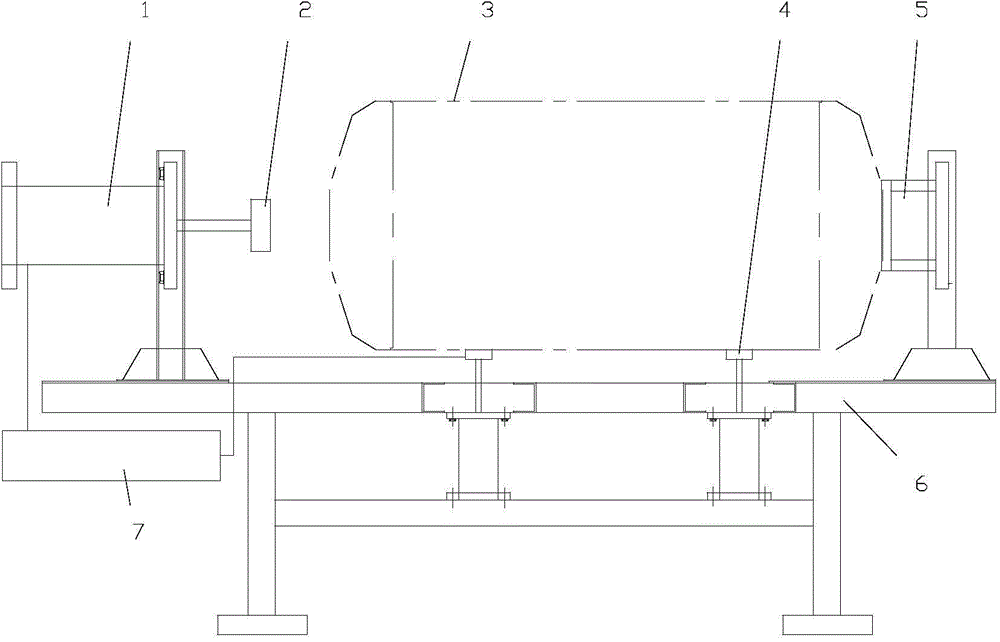

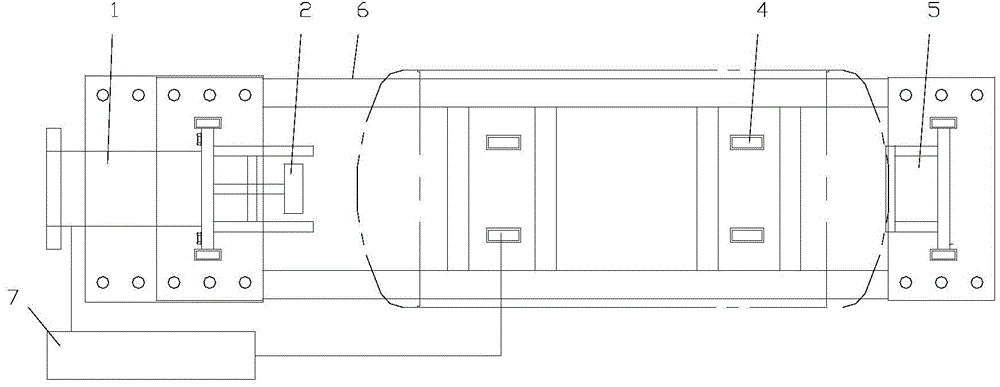

[0010] Such as figure 1 , 2 As shown, the left end of the frame 6 is fixed to push the cylinder 1, the front end head clamping device 2 is fixed on the piston of the push cylinder 1, the rear end of the frame 6 is fixed to the rear end head clamping device 5, and the middle part of the frame 6 is fixed The gas cylinder rotary jacking device 4, the air supply device 7 is also fixed on the frame 6, and the gas supply device 7 is sealed and communicated with the propulsion cylinder 1 and the gas cylinder rotary jacking device 4.

[0011] The gas supply device 7 includes a liquid nitrogen storage tank, a self-pressurized vaporizer, a liquid nitrogen pump, an air-temperature vaporizer and a water-bath vaporizer. The gas supply system 7 is connected with the workshop pipeline gas source, and the gas supply pressure is not lower than 0.5Mpa.

[0012] The rotary part of the gas cylinder rotary jacking device 4 adopts four universal balls to facilitate the forward and backward moveme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com