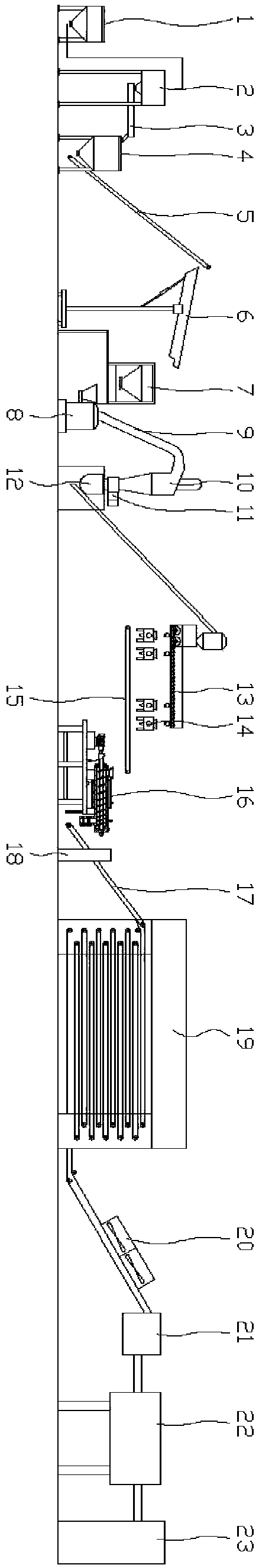

Extrusion rice noodle production method and production line

A production process and production line technology, applied in the field of powder pressing production process and production line, can solve the problems of inability to meet modern production, poor quality of pressed powder, and unstable powder thickness and quality, so as to reduce manual participation and reduce manual intervention. , the effect of improving taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

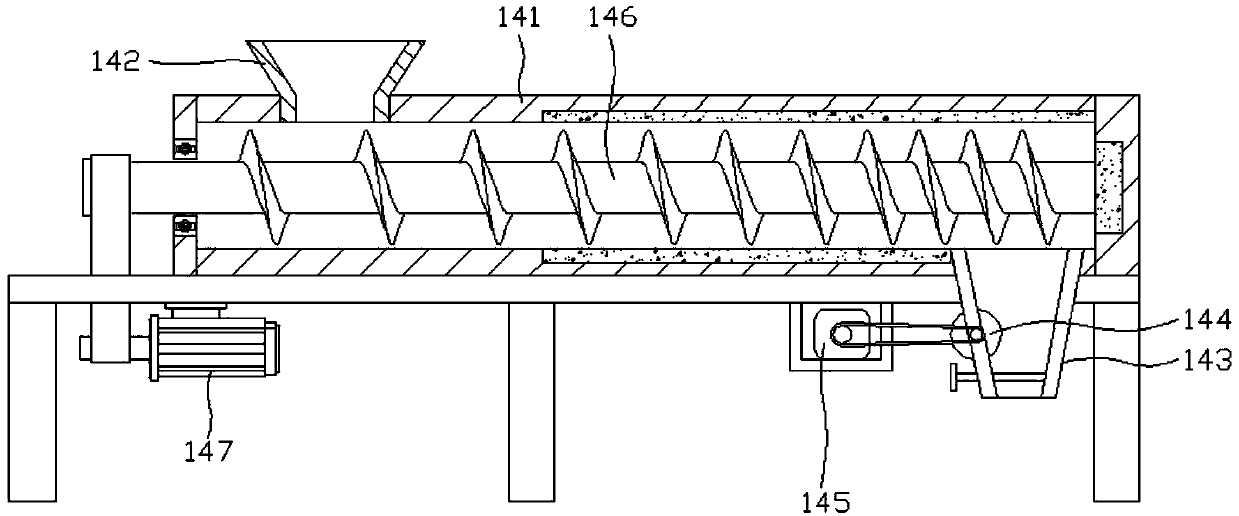

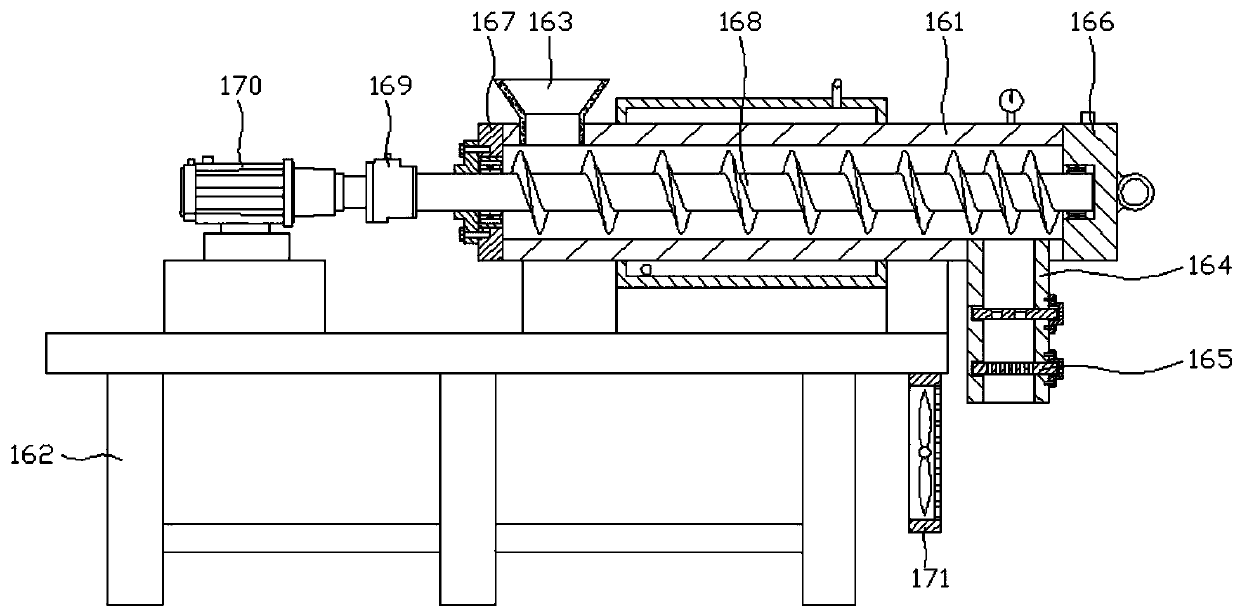

[0034] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention. .

[0035] A powder pressing production process, comprising the following steps:

[0036] Step 1: Select the rice with full grains and no insects to be transported to the desanding equipment by the first elevator for impurity removal and cleaning, and the cleaned rice is transported to the soaking rice tank through the rice distributor for soaking;

[0037] Step 2: Use the second elevator to put the rice in step 1 into the jet rice washing machine for re-cleaning, and then put it into the water filter bucket for water and rice separation, and the rice separated from the water falls into the pulverizer stor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com