Micro-channel plate heat exchanger with triangular corrugated flowing channel

A technology of micro-channel plate and channel plate, which is applied in heat exchanger types, indirect heat exchangers, heat exchange equipment, etc., to reduce production difficulty, expand heat exchange area, and save production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

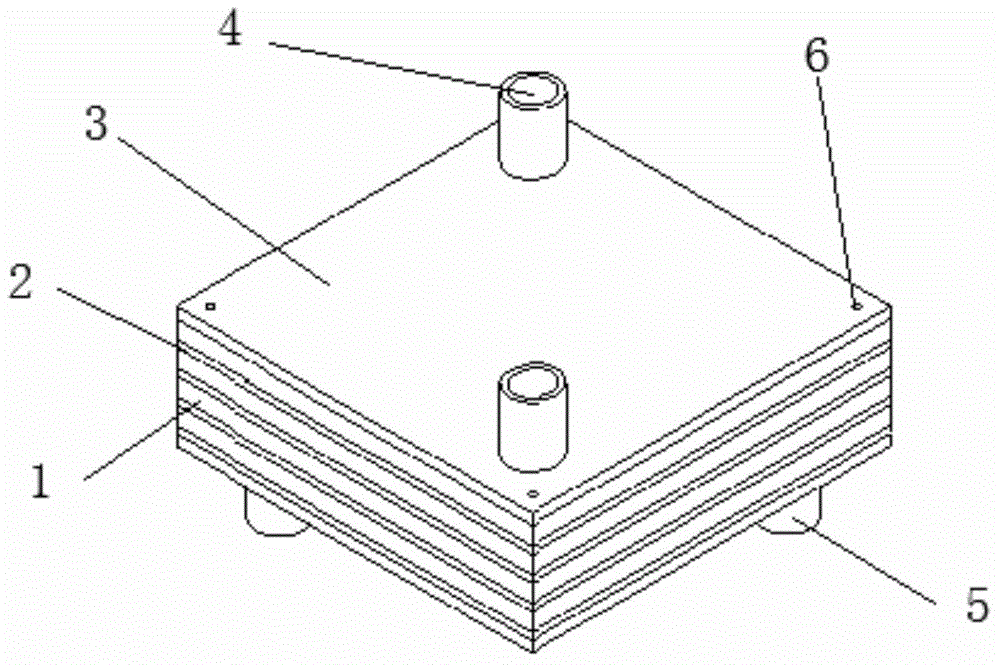

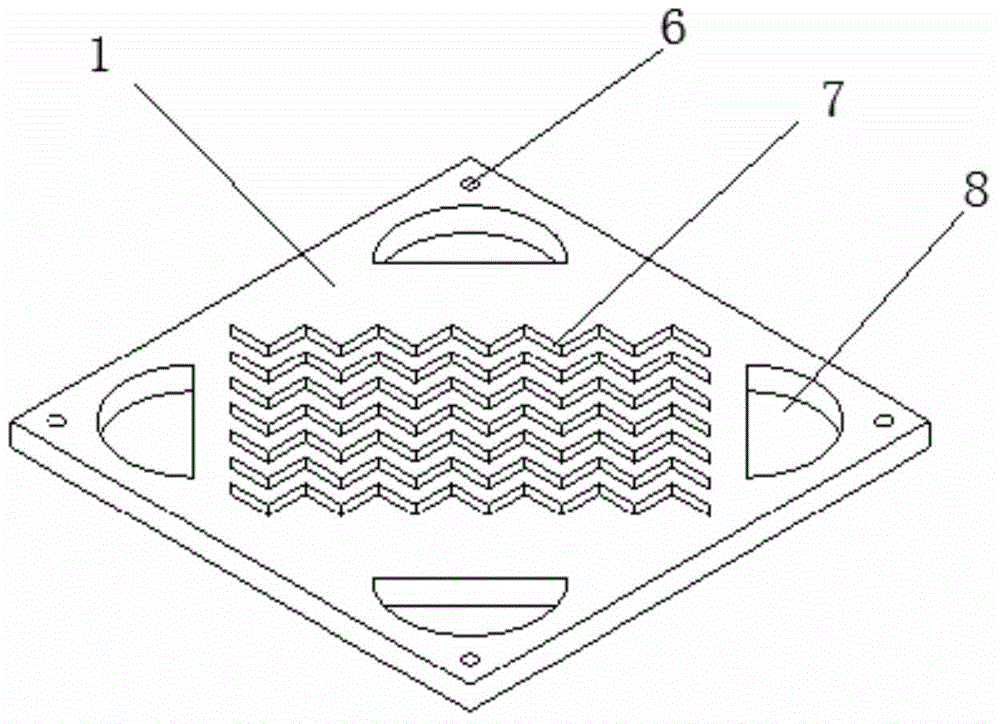

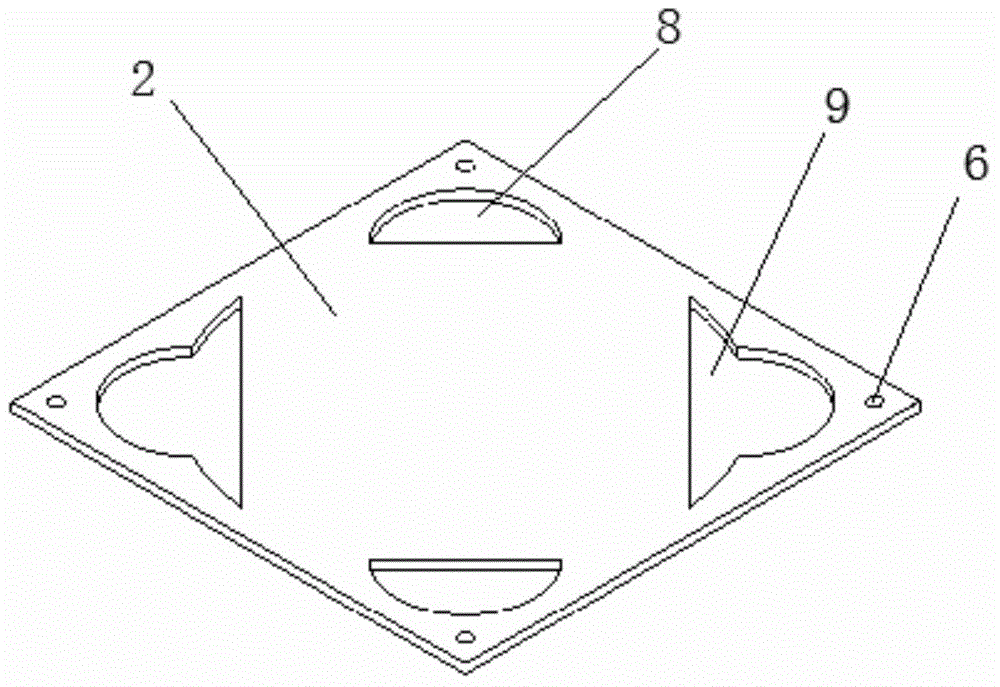

[0031] refer to Figure 1 to Figure 8 , the present invention includes a channel plate 1, a partition plate 2, a clamping plate 3, a hot fluid inlet and outlet 4, a cold fluid inlet and outlet 5 and a liquid collection hole channel 8; the two sides of the channel plate 1 are provided with a partition plate 2 , the channel plate 1 and the spacer plate 2 are alternately stacked and pressed to form a hot and cold fluid heat exchange channel 7, and the spacer plate 2 is provided with a fluid distribution channel 9, and the cold and hot fluid heat exchange channel 7 is connected with the fluid distribution channel 9, so The four corners of the channel plate 1 are provided with a liquid collection hole channel 8; the outer side of the channel plate 1 and the interlayer plate 2 is provided with a clamping plate 3, and the clamping plate 3 is provided with a hot fluid inlet and outlet 4 and a cold The fluid inlet and outlet 5, the hot fluid inlet and outlet 4 and the cold fluid inlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com