Method for preparing high-purity biodiesel

A technology of biodiesel and crude oil, applied in the direction of biofuel, carboxylic acid ester preparation, chemical instruments and methods, etc., can solve the problem of slow separation of glycerin and fatty acid methyl ester, inability to completely convert neutral oil, increase equipment cost and Energy consumption and other issues, to achieve the effects of shortening the miscible time, sufficient transesterification reaction, and saving labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

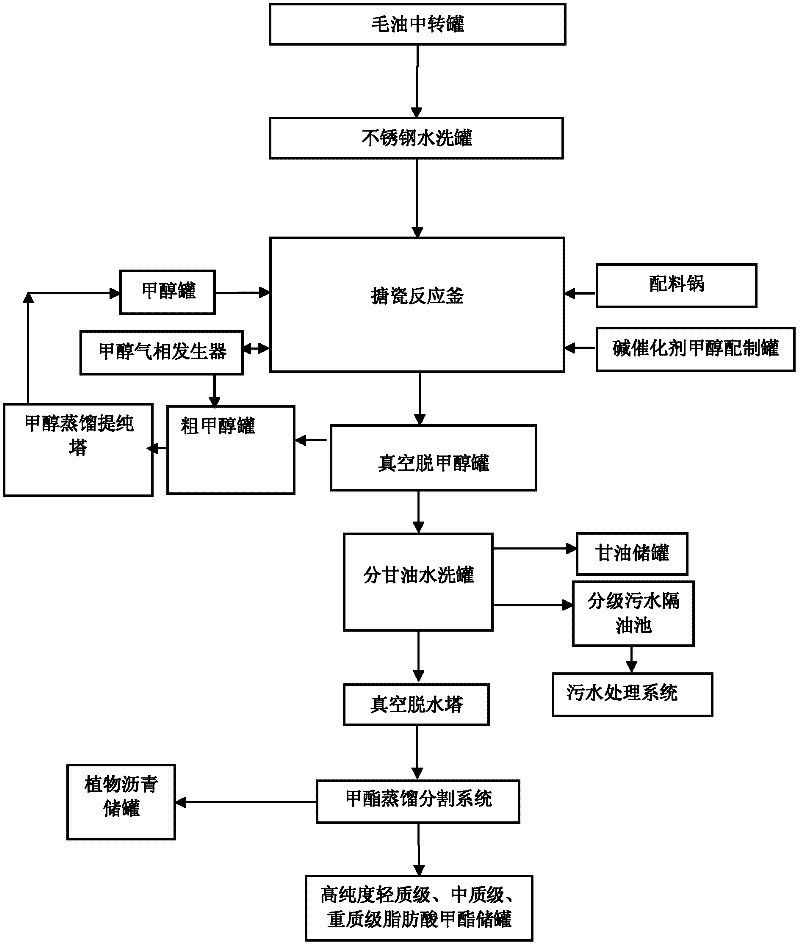

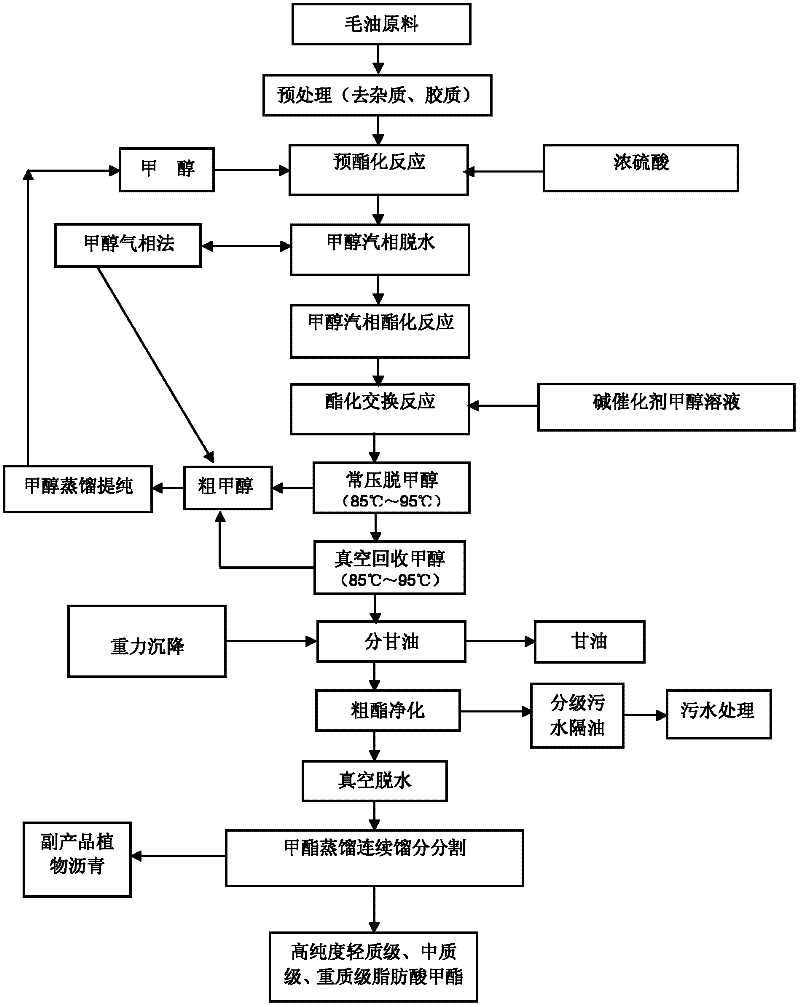

Method used

Image

Examples

Embodiment 1

[0047] Put 1200kg of methanol into the batching pot in advance, and start stirring, then add 45kg of concentrated sulfuric acid, stir well and set aside. Wash 8 tons of waste oil recovered in the crude oil transfer tank in a stainless steel water washing tank, and after vacuum dehydration, put it into the enamel reaction kettle together with the prepared sulfuric acid methanol solution, open the jacket of the reaction kettle and steam to heat to 70°C or so, for 30 minutes. Continue to open the steam inlet valve and adjust the methanol reflux valves to recover the crude methanol condensed by the methanol condenser to the crude methanol tank. When the liquid phase temperature reaches 110-115°C, open the methanol feed bottom valve of the reactor, open the fresh methanol pump, open the methanol flow meter control valve, and start to replenish vapor phase methanol through the methanol gas phase generator, and the feed flow rate is controlled at 500L / h; after 2 hours, take a sampl...

Embodiment 2

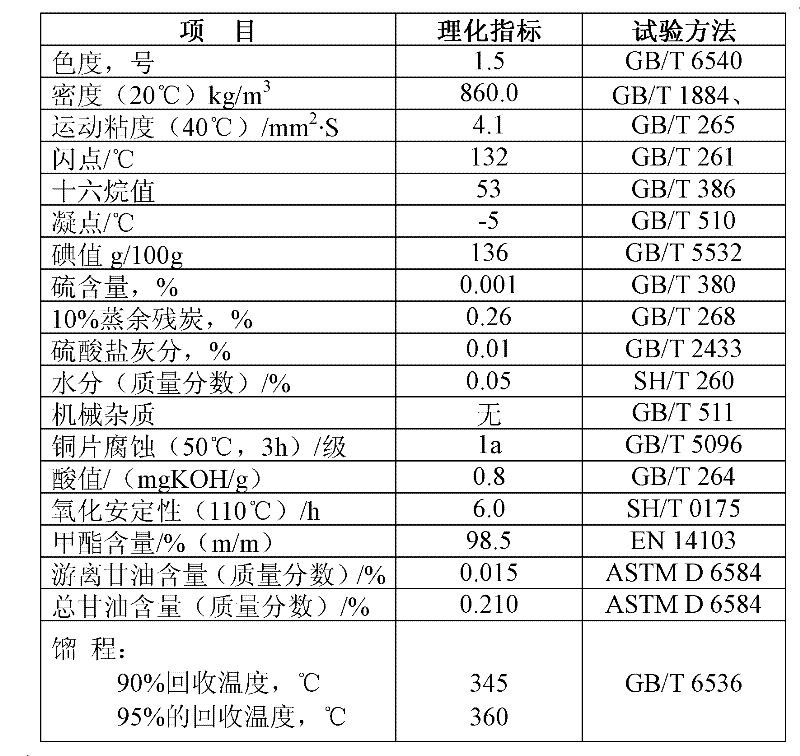

[0060] The biodiesel obtained in Example 1 was compared with the performance parameters of national standard No. 0 fossil diesel (according to GB252-2000 standard), and the results are shown in Table 2.

[0061] Table 2 The biodiesel measured value of the present invention is compared with conventional fossil diesel parameters

[0062]

[0063]

[0064] According to the results in Table 2, it can be seen that the biodiesel prepared by the method of the present invention fully meets or even exceeds the basic technical requirements of the national standard No. 0 fossil diesel, and can be used as a substitute for fossil diesel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com