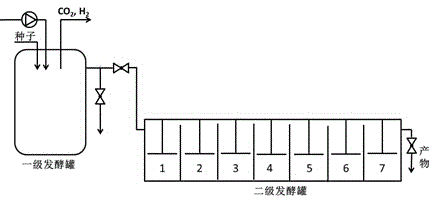

Device and method for producing butyl alcohol through continuous fermentation of lignocellulose

A technology for lignocellulose and butanol, which is applied in the directions of microorganism-based methods, biochemical cleaning devices, biochemical equipment and methods, etc., can solve the problems of complicated operation and increase of data detection points, and achieves simple fermentation equipment and improved utilization. The effect of high efficiency and production intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Clostridium acetobutylicum ( Clostridium acetobutylicum ) ATCC 824, purchased from the American Type Culture Collection. The fermentation medium uses the above-mentioned lignocellulose hydrolyzate as the carbon source, the total sugar concentration is 80g / L, and the following nutrients are added in g / L: Yeast 1.0, CH 3 COONH 4 2.2, KH 2 PO 4 0.5,K 2 HPO 4 0.5, MnSO 4 0.01, NaCl 0.01, MgSO 4 ?7H 2 O 0.2, FeSO 4 0.01, p-aminobenzoic acid 0.001, vitamin B 1 0.001, biotin 0.01×10 -3 . The fermented seed solution was obtained by inoculating Clostridium acetobutylicum ATCC 824 into the RCM seed medium and culturing at 37 °C for 20 h under anaerobic environment.

[0032] Using the continuous fermentation operation mode described in the present invention, add the above-mentioned fermentation medium into the first-stage fermenter, the addition amount is half of the volume of the fermenter, and insert the butanol fermenting bacteria seed liquid for cultivation,...

Embodiment 2

[0037] The treatment process and operating conditions are the same as in Example 1, except that Clostridium beijerinckii CM20 is used, the fermentation medium uses the above-mentioned lignocellulose hydrolyzate as a carbon source, the concentration of reducing sugar is 60g / L, and the following nutrients are added, Calculated in g / L: Yeast 1.0, CH 3 COONH 4 2.2, KH 2 PO 4 0.5,K 2 HPO 4 0.5, MnSO 4 0.01, NaCl 0.01, MgSO 4 ?7H 2 O 0.2, FeSO 4 0.01, p-aminobenzoic acid 0.001, vitamin B 1 0.001, biotin 0.01×10 -3 . The fermented seed solution was obtained by inoculating Clostridium beijerinckii CM20 into the RCM seed medium and culturing at 37 °C for 20 h in an anaerobic environment. Control the dilution rate of the primary fermenter at 0.03h -1 , taking the first overflow of the fermentation broth from the secondary fermenter as the starting point of continuous fermentation, the results are shown in Table 2 below.

[0038] The fermentation result of table 2 embo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com