Method for treating glyphosate mother liquid

A technology of glyphosate mother liquor and processing method, applied in the field of glyphosate mother liquor treatment of catalyst triethylamine recovery rate, can solve the problems of rising production cost, high consumption of triethylamine, reduced possibility of industrialized production, etc. The effect of slow heat transfer efficiency, low production intensity and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

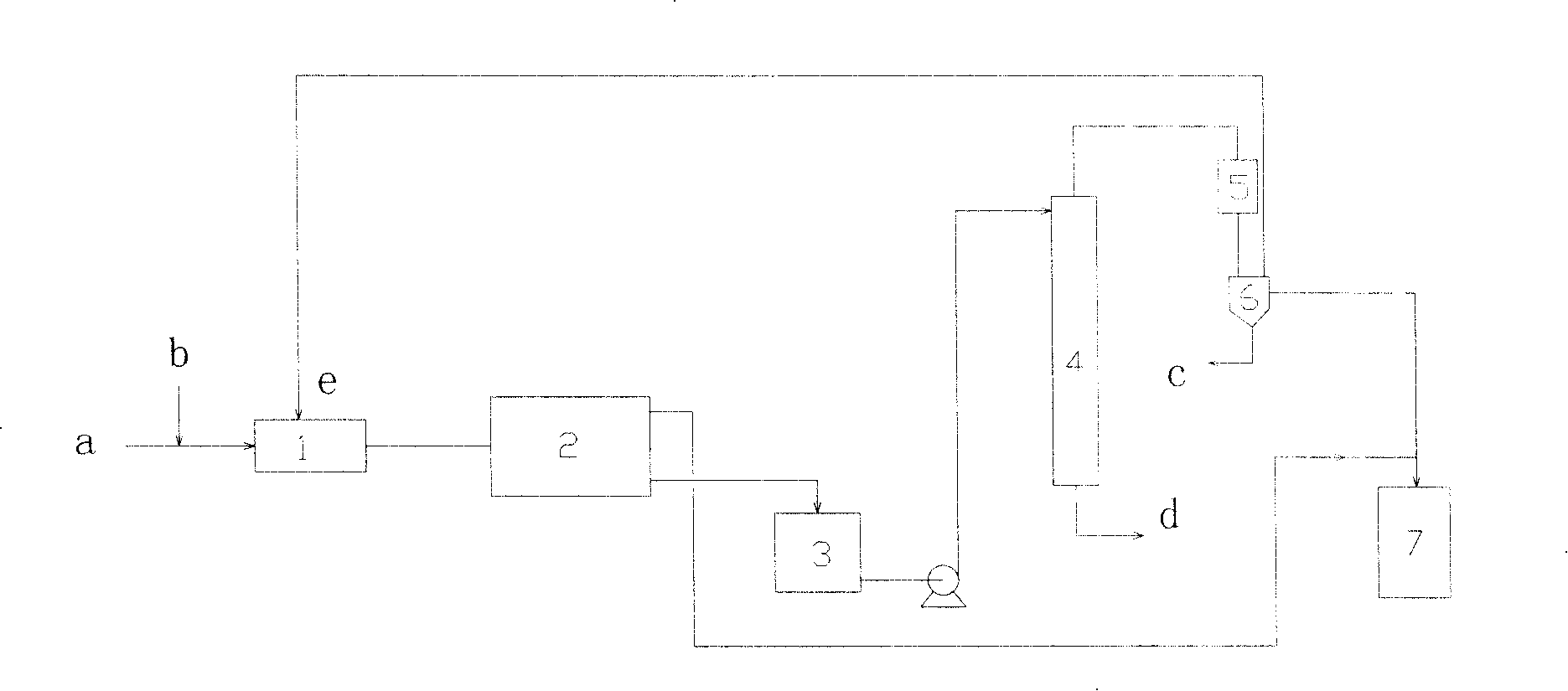

[0029] in the attached figure 1 In the process of glycine method synthesis, the mother liquor and ammonia gas filtered out of glyphosate crystallization are placed in the static mixer 1, and the glyphosate mother liquor is now treated with ammonia.

[0030] The flow rate of the glyphosate mother liquor is 166.7kg / h, adjust the flow rate of the ammonia gas, neutralize the two in a static mixer, and control the temperature within the range of -5°C to 15°C. The neutralization solution flowing out of the outlet of the static mixer directly enters the gravity chromatograph 2 for stratification, the amine phase of the upper layer enters the triethylamine tank 7 for dehydration treatment, and then returns to the glyphosate synthesis process, and the water phase of the lower layer enters the large mother liquor tank 3. Then the pump enters the rectification tower 4 for rectification, and the discharge from the tower kettle goes to the mother liquor concentration process. After concent...

Embodiment 2

[0034] Add 300g 99% methanol into a reactor equipped with a stirrer, first add 60g 98% triethylamine under stirring, then add 40g 93% paraformaldehyde, keep warm at 40°C for 60 minutes; add 45g 97.5% glycine, 50 Insulate at ℃ for 60 minutes; add 80g 98% dimethyl phosphite, and insulate at 65℃ for 95 minutes; cool the material to 30℃, add 200g 30% hydrochloric acid, heat up to 120℃, add 25g water when cooling to 95℃, drop Add 43g of 25% ammonia solution, so that the pH is 0.9; cool and crystallize, filter and dry to obtain 79.2g of glyphosate technical substance, the content is 95.2%, and the yield is 76.3%. The filtrate is the glyphosate mother liquor.

[0035]Take all the glyphosate mother liquor synthesized above, feed 25.2g of ammonia gas, so that the pH is 7.6, and control the process temperature between 60°C and 110°C. The mother liquor was left to stand for stratification, and 23.4g of triethylamine was obtained in the upper layer. The mother liquor in the lower layer wa...

Embodiment 5

[0037] Get all the glyphosate mother liquor prepared by the operation method in Example 2, feed 48.3g of ammonia gas, so that the pH is 10.5, and control the process temperature between 20°C and 60°C. The mother liquor was left to stand for stratification, and 44.8g of triethylamine was obtained in the upper layer. The mother liquor in the lower layer was distilled and the fraction below 110°C was collected. Ethylamine, which is equivalent to a total recovery rate of 85.9%; after the remaining mother liquor is distilled under reduced pressure, it is cooled to normal temperature, and filtered to obtain 30.4 g of ammonium chloride crystals (content 84.0%), and the concentrated mother liquor content is 3.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com