Method for recovery of waste heat of steel slag and comprehensively processing and utilizing steel slag

A technology of waste heat recovery and comprehensive processing, applied in the field of steel slag treatment, to avoid water explosion, solve environmental pollution problems, and prevent quality decline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

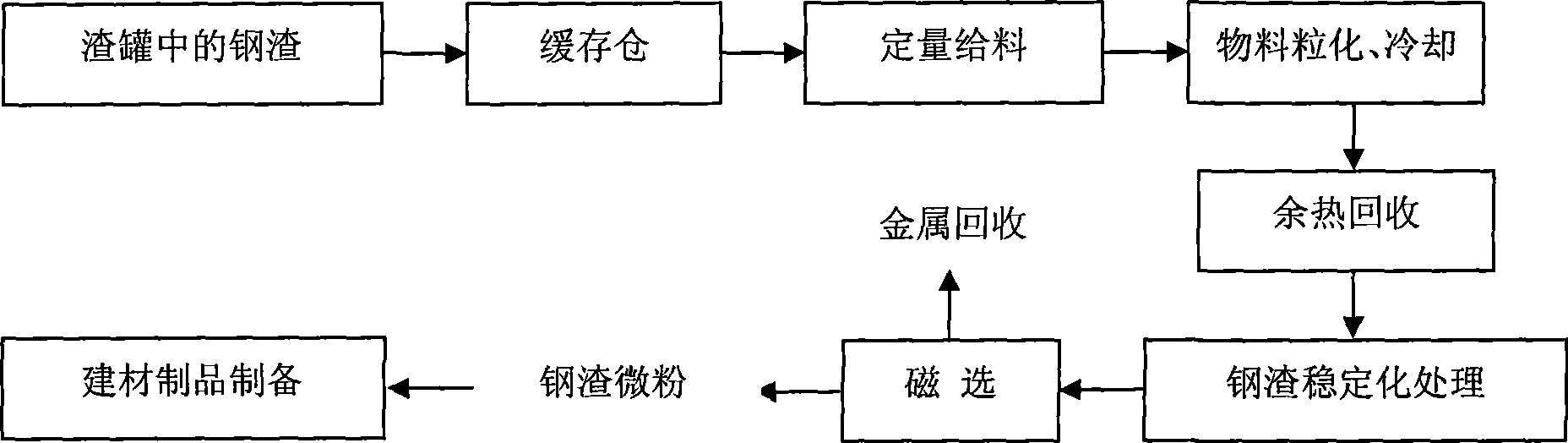

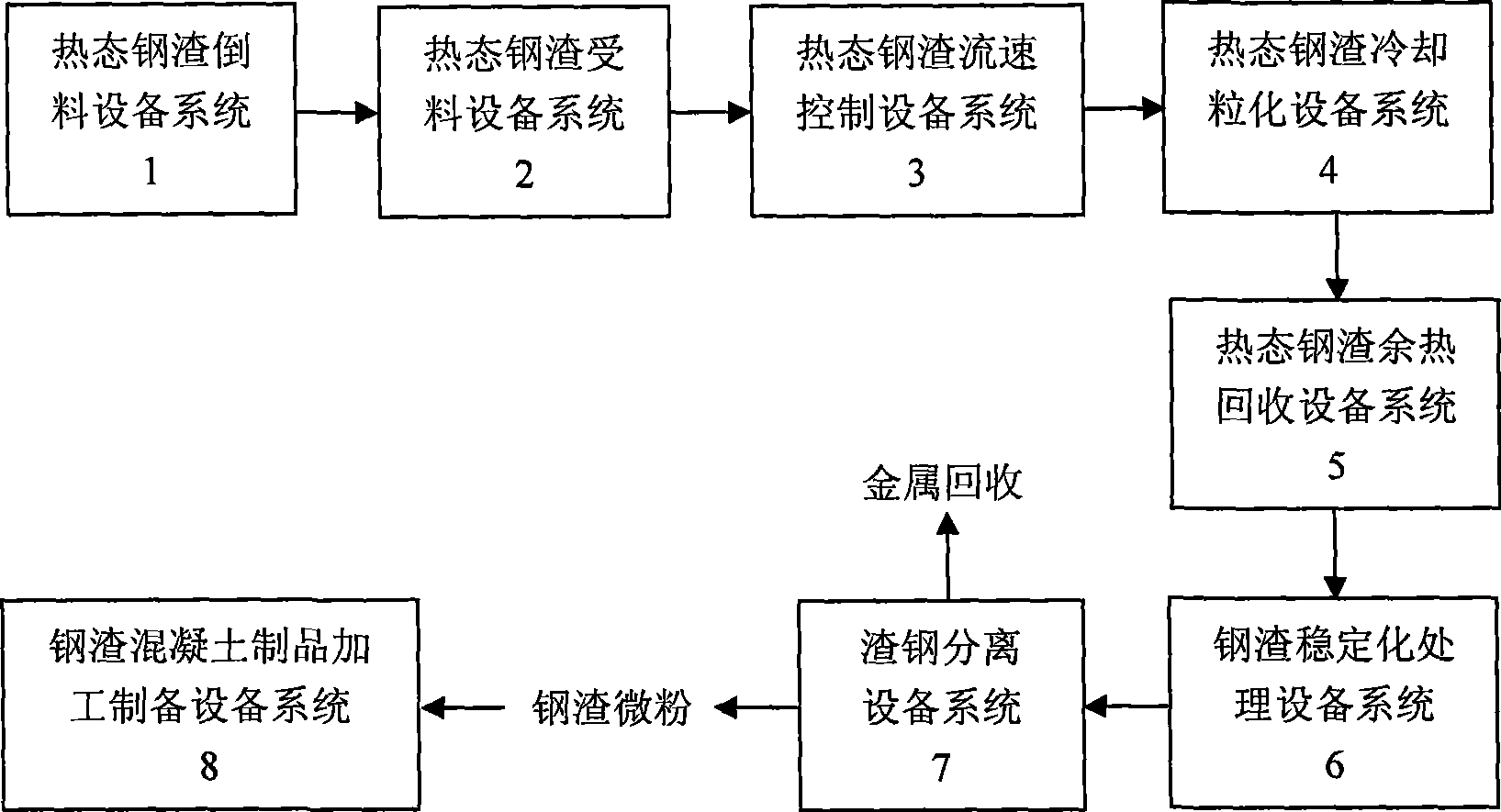

[0029] The invention relates to a treatment method for steel slag waste heat recovery and comprehensive processing and utilization of steel slag, which realizes the combination of steps figure 1 Described as follows:

[0030] (1) Hot steel slag enters the steel slag receiving system while performing preliminary granulation through the discharging system during the discharging process;

[0031] (2) The hot steel slag passes through the flow rate control system to realize the quantitative feeding of the subsequent process, and realizes the secondary granulation of the hot steel slag in the system;

[0032] (3) After preliminary cooling and granulation, the hot steel slag enters the steel slag waste heat recovery system. Since the surface of the hot steel slag is continuously renewed in this system, the heat in the steel slag is completely and evenly released, and the steel slag waste heat is recovered in the form of hot air and steam. , and at the same time realize the granulat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com