Water-cooled slag groove

A water-cooled slag and water-cooled tank technology, which is applied in the field of steel rolling, can solve the problems of inability to cool the slag at high temperature, and the slag with molten iron burst, so as to ensure the flow performance, reduce the temperature of the slag, and avoid the effect of water burst.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

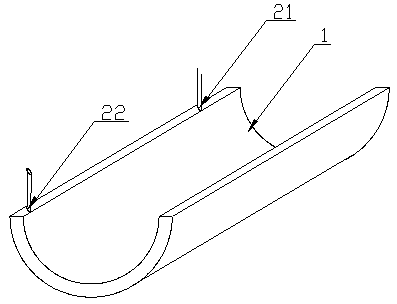

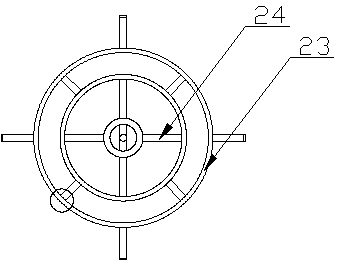

[0030] This embodiment provides a water-cooled slag groove, such as figure 1 As shown, it includes a water-cooling tank 1 made of steel. A water-cooling chamber 2 is arranged in the water-cooling chamber 1. A partition plate is used to separate a cooling channel in the water-cooling channel 2. A circulating water inlet 21 is provided at one end of the cooling channel. One end is provided with a circulating water outlet 22 .

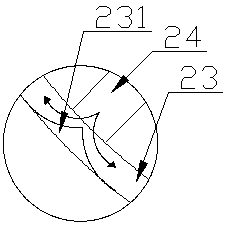

[0031] Applying the characteristics of high-efficiency and rapid heat exchange of steel, the steel plate is used to roll the slag groove according to the required size of the slag groove to replace the slag groove drop opening constructed by the original refractory brick and ramming material. The upper and lower surfaces of the slag groove are preferably semi-circular arcs, and the middle In the water cooling chamber 2, a circular cooling water channel is made in the form of a clapboard labyrinth, and the inlet and outlet of the circulating water are exte...

Embodiment 2

[0033] In this embodiment, on the basis of Embodiment 1, it is further defined that: both the inlets and outlets of the circulating water are in communication with the blast furnace cooling soft water system.

Embodiment 3

[0035] In this embodiment, on the basis of Embodiment 1, it is further defined that: the cooling water channels are arranged in a serpentine shape and more than two cooling water channels are arranged in the water cooling cavity 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com