Heat pump air-conditioning system of electric vehicle

A heat pump air conditioner and electric vehicle technology, applied in air conditioning systems, home heating, heating methods, etc., can solve the problems of heat absorbed by the heat exchanger outside the car, the system cannot continue to provide heating functions, and the system cannot continue to operate, etc., to achieve improvement Operating environment, the effect of increasing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

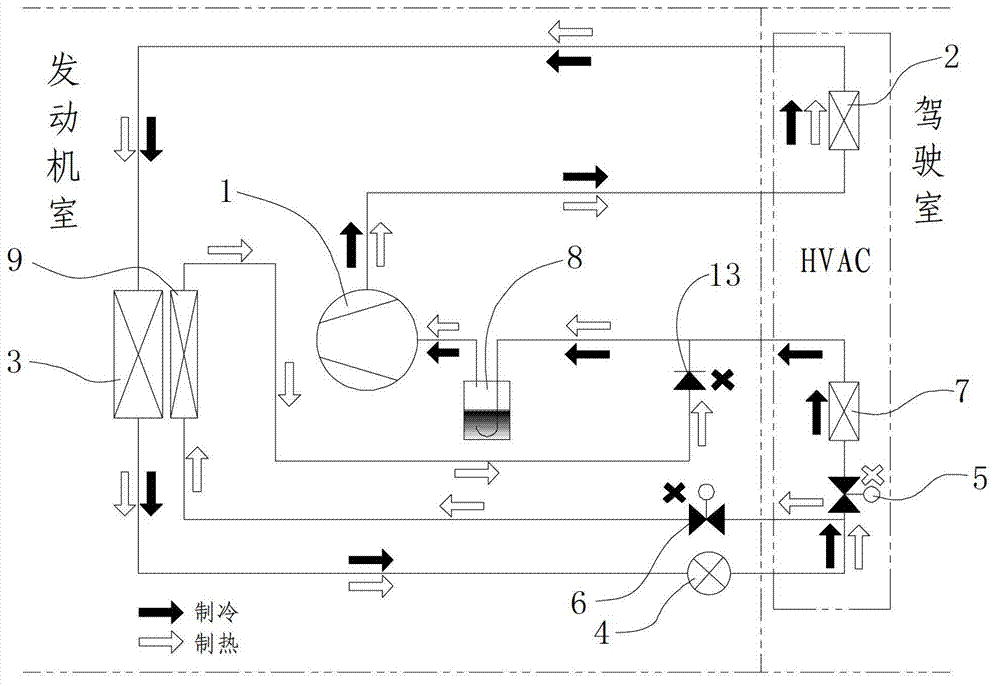

[0026] see figure 1 , electric vehicle heat pump air conditioning system, including compressor 1, interior condenser 2, exterior condenser 3, expansion valve 4, first stop valve 5, second stop valve 6, interior evaporator 7 and liquid-gas separator 8. It also includes an exterior evaporator 9, which is arranged behind the exterior condenser. According to the flow direction of the refrigerant, the outlet of the compressor and the inlet of the condenser outside the vehicle are connected through pipelines to form a first stroke section, and the condenser inside the vehicle is connected in series on the stroke section. A second travel section is formed between the inlet and the outlet of the exterior condenser. A third stroke section is formed between the outlet of the exterior condenser and the inlet of the liquid-gas separator, and this stroke section includes the first branch circuit and the second branch circuit formed by the first shut-off valve and the interior evaporator ...

Embodiment approach 2

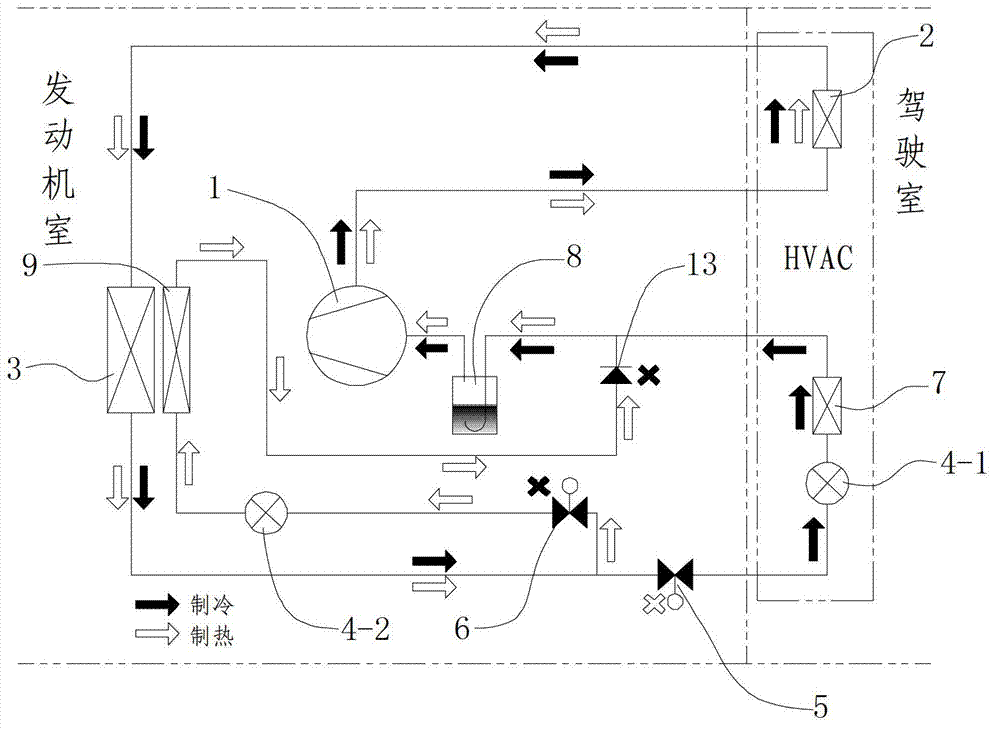

[0031] see figure 2 , the difference between this embodiment and Embodiment 1 is that there are two expansion valves, and the inlet of one expansion valve (referred to as the first expansion valve 4-1 here) is connected to the outlet of the first cut-off valve. The outlet of the valve is connected with the inlet of the evaporator inside the vehicle; the inlet of another expansion valve (called the second expansion valve 4-2 here) is connected with the outlet of the second cut-off valve, and the outlet of the expansion valve is connected with the outlet of the evaporator outside the vehicle. The import is connected.

[0032] For the working principle of this embodiment, please refer to Embodiment 1. The difference from Embodiment 1 is that in Embodiment 1, an expansion valve is used to control the first branch and the second branch. An expansion valve, independently controlled.

Embodiment approach 3

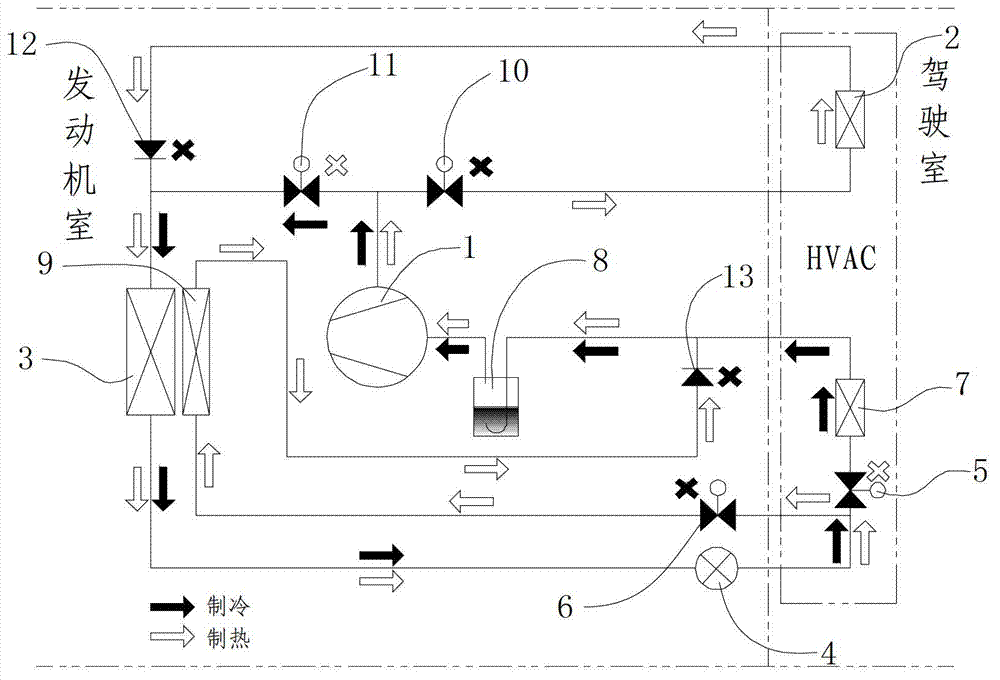

[0034] see image 3 , The difference between this embodiment and Embodiment 1 is that: the third stop valve 10 and the fourth stop valve 11 are installed on the first stroke section. The outlet of the compressor is respectively connected with the inlet of the third shut-off valve and the inlet of the fourth shut-off valve through a three-way joint. According to the flow direction of the refrigerant, the third cut-off valve is connected in series with the interior condenser to form a third branch, and the fourth branch is formed between the inlet and outlet of the fourth cut-off valve, and the third branch and The fourth branch is connected in parallel.

[0035] How this implementation works:

[0036]During the heating cycle, the third cut-off valve is opened and the fourth cut-off valve is closed. The refrigerant is compressed by the compressor and becomes a high-temperature and high-pressure gaseous refrigerant. During the heat release process, the surrounding air is heate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com