Smelting method and device of molten lead oxidation slag

A technology of lead oxide slag and smelting method, which is applied in the smelting of molten lead oxide slag, and realizes the device field of the smelting method, and achieves the effects of saving energy, reducing production equipment, and saving engineering investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

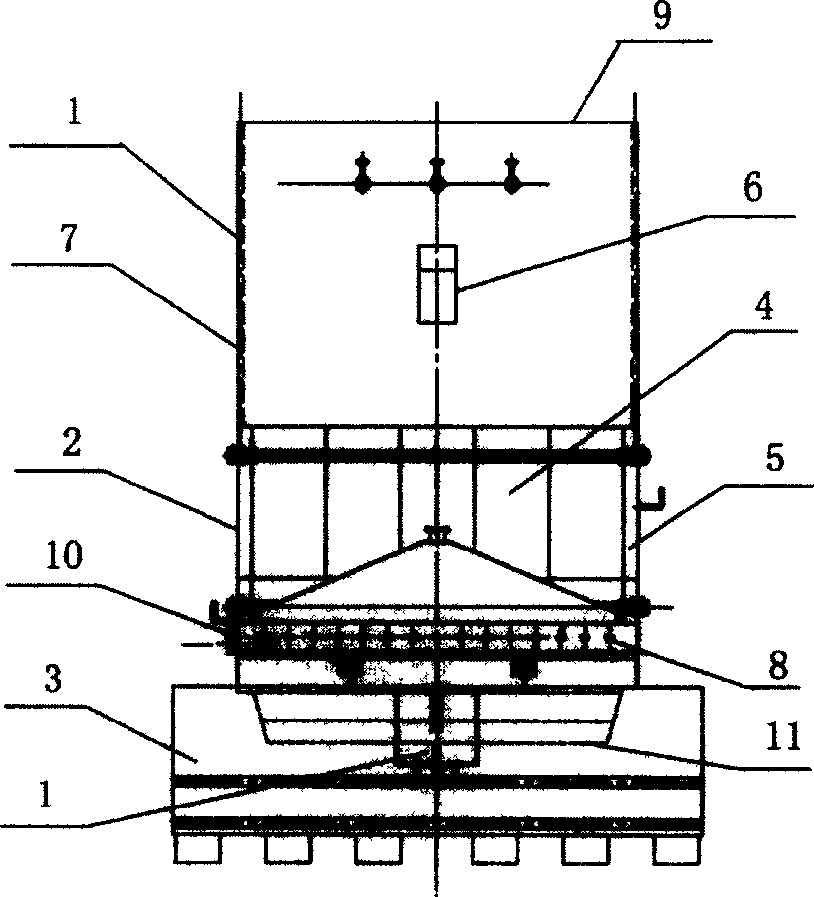

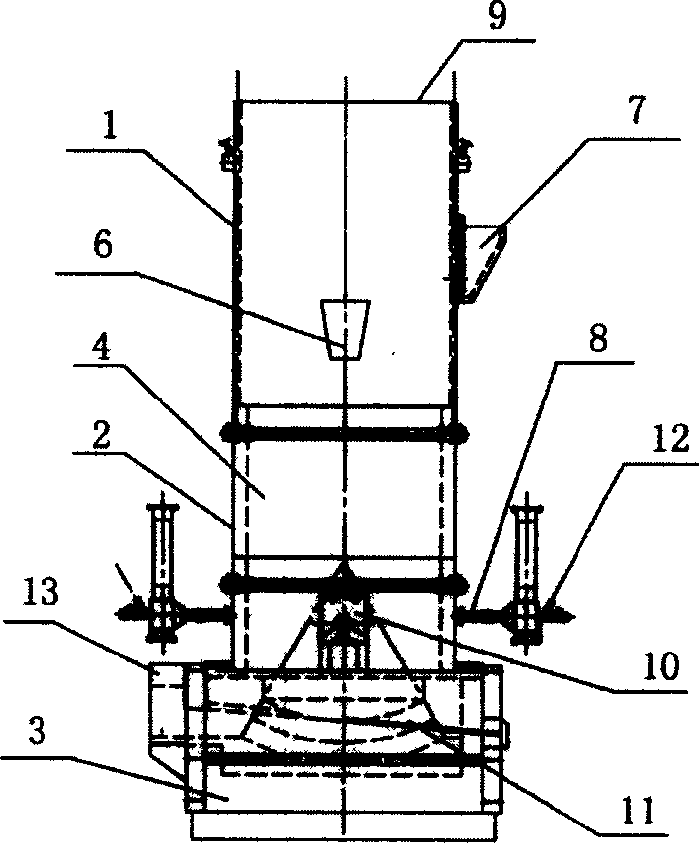

[0032] Embodiment one sees figure 1 , 2 , the specific method of smelting high-lead slag using a single side-blowing furnace includes the following process:

[0033] The furnace body adopted is a vertical side-blowing furnace, the interior of the furnace body is a melting pool 4, the furnace wall is a water jacket 5 or a membrane wall structure, the top of the upper furnace body 1 is provided with a smoke exhaust port 9, and the side wall of the upper furnace body 1 A lead oxide slag feed port 6 and a flux feed port 7 are respectively provided. The side wall of the lower furnace body 2 is provided with a nozzle inlet 8 and a slag discharge port 10. The bottom of the lower furnace body is connected to the bottom furnace body 3, and the inside of the bottom furnace body is an inverted arch. Bottom-shaped structure 11, the bottom is lined with refractory material, and a siphon lead outlet 13 is opened on the side wall.

[0034] Adopt the smelting method of above-mentioned side ...

Embodiment 2

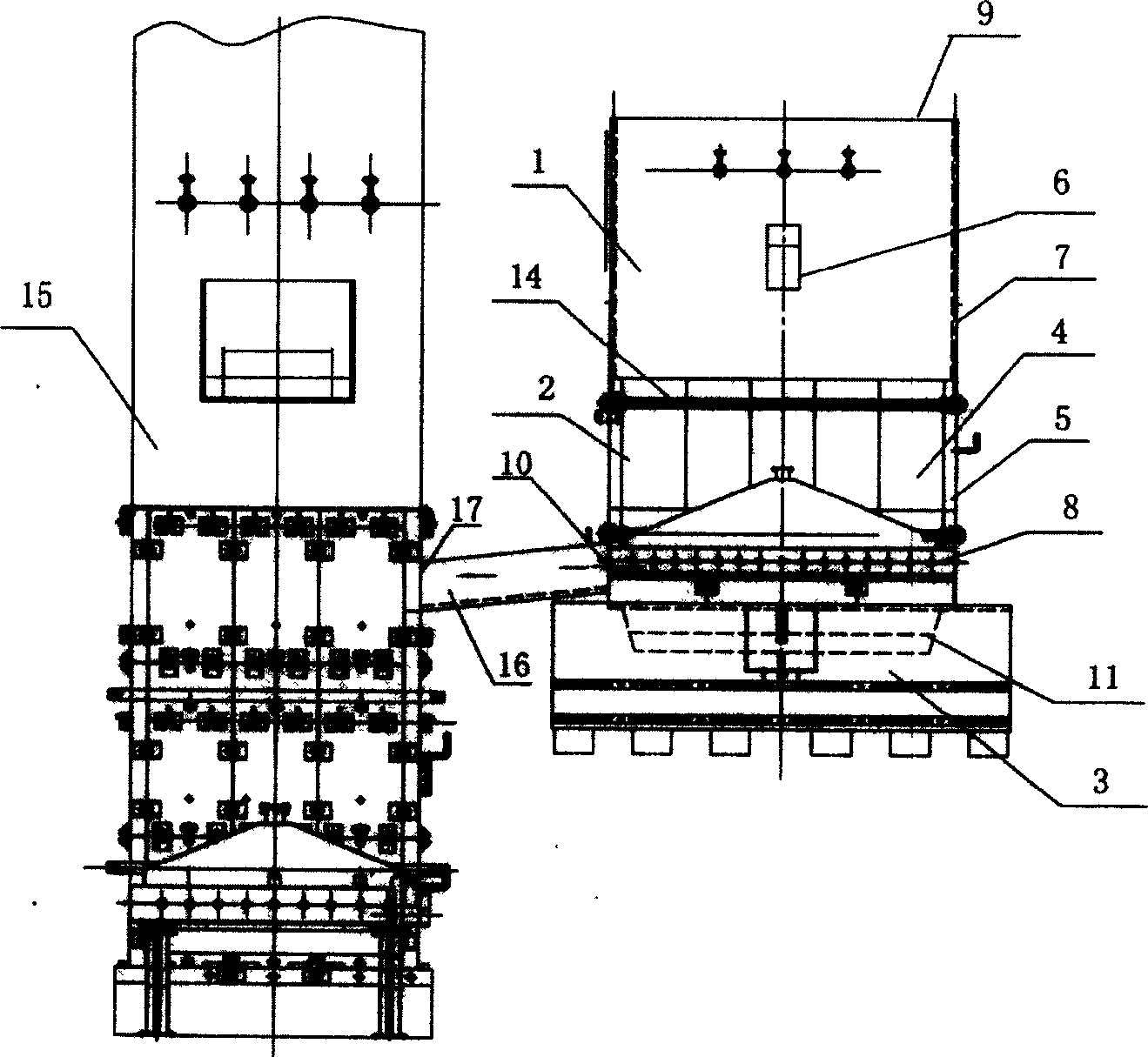

[0038] Embodiment two see image 3 : a molten lead oxide slag smelting device and a common fuming furnace are connected in series, and the slag outlet 10 of the molten lead oxide slag smelting device is communicated with the hot slag inlet 17 of the common fuming furnace 15 with a chute 16 .

[0039] see Figure 4 , its molten lead oxide slag smelting method:

[0040] In the side blowing furnace, the reduction process of the first stage is the same as that of the first embodiment. The residual slag produced in the first stage is discharged from the slag discharge port of the furnace body, and enters the second side-blowing furnace for fuming blowing. The temperature of the molten pool is 1150-1300 °C; air and reducing agent pass through the nozzle inlet It is sprayed into the molten pool from the side of the furnace, and the oxygen concentration of the air blown in is 23%-40%; after the slag is fumed in the second stage, it produces flue gas and waste slag containing zinc ox...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com