Primary cooling process for coal gas

A gas and process technology, applied in the direction of gas dust removal, liquid washing gas purification, etc., can solve the problems of high management requirements, high investment costs, easy blockage of heat exchangers, etc., achieve high cooling efficiency, reduce blockage, and improve equipment operating environment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

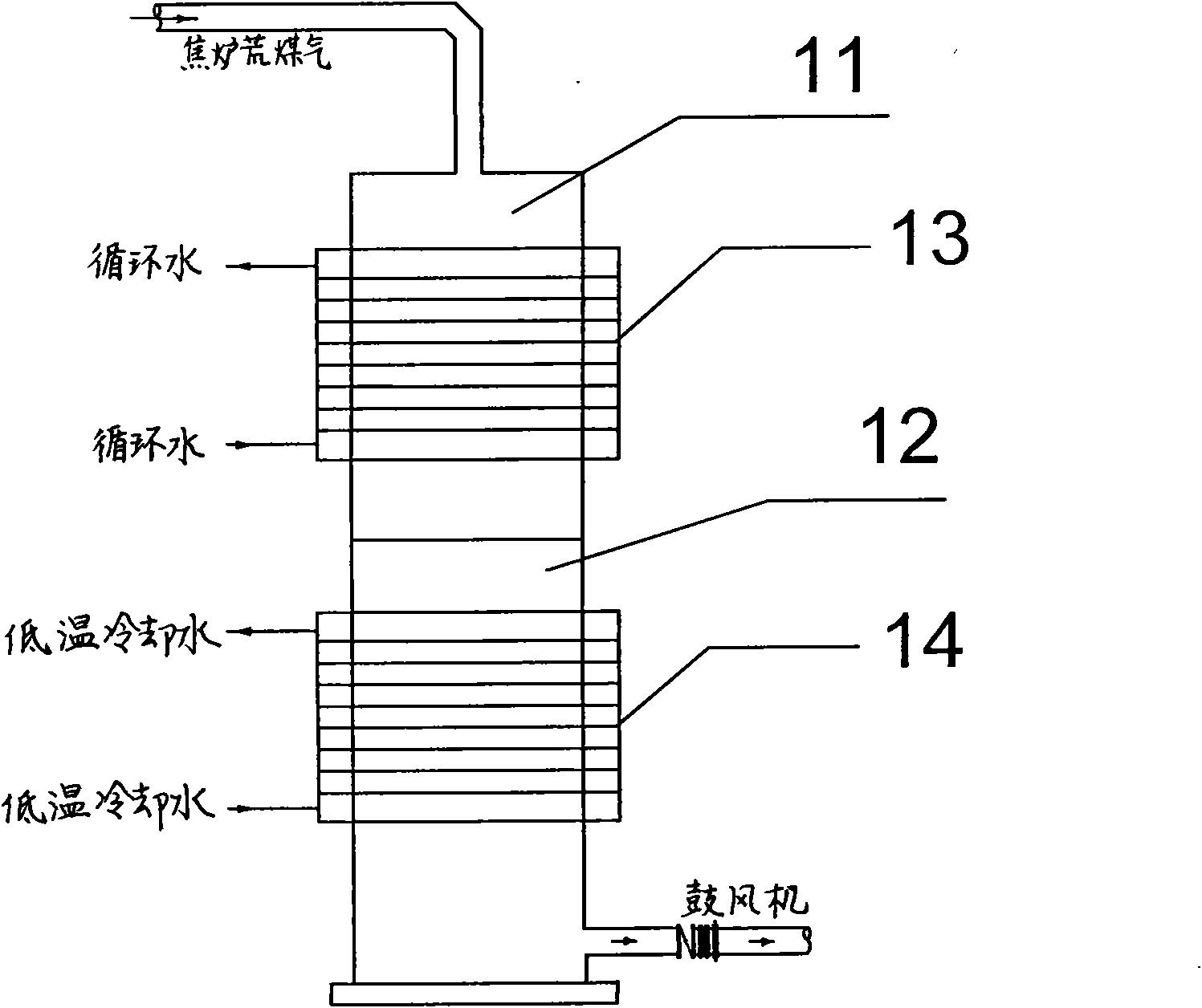

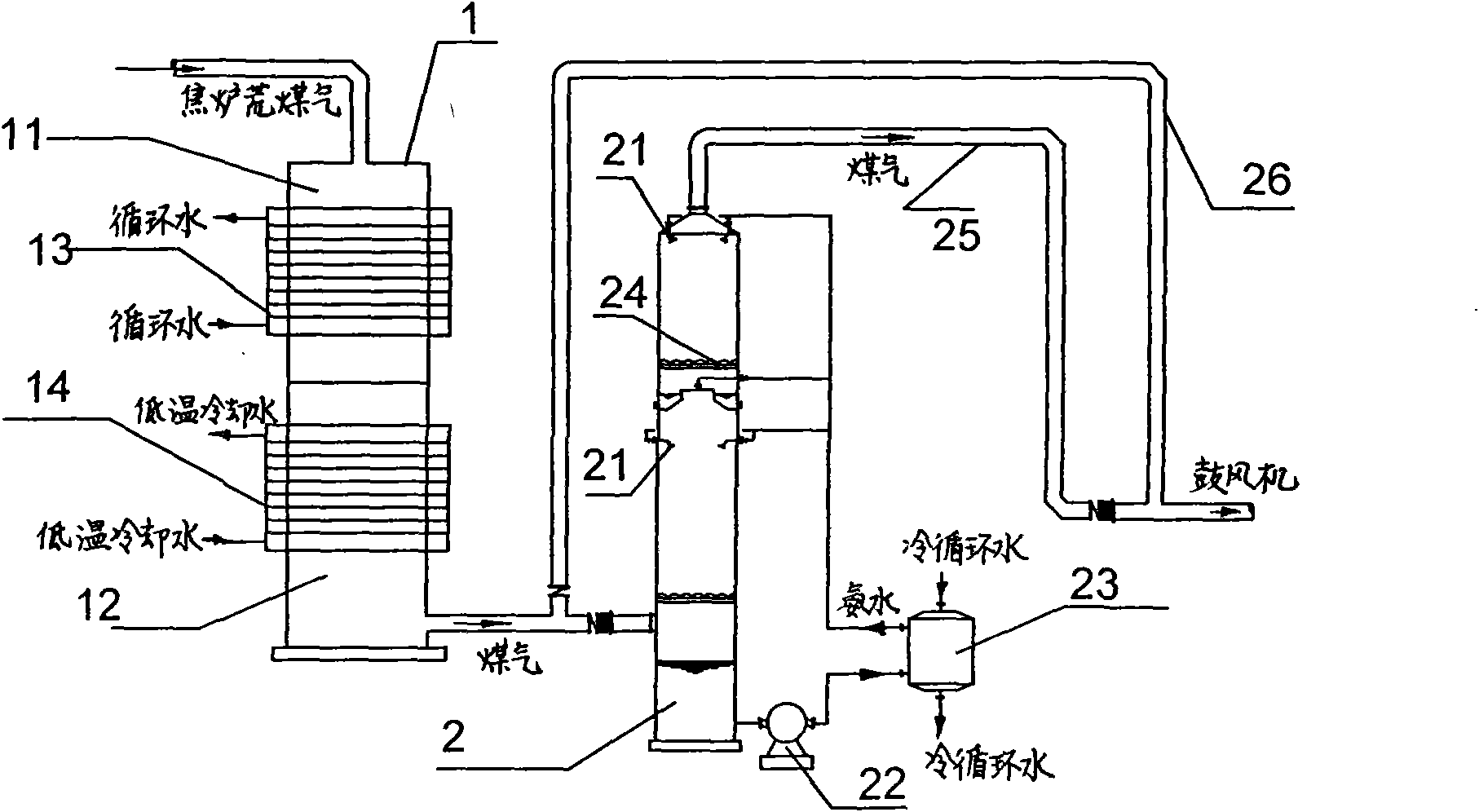

[0025] equipment such as image 3 As shown, the horizontal tube primary cooler 1 is connected to the coke oven, and the horizontal tube primary cooler is divided into a circulating water section 11 and a low-temperature cooling water section 12; in the circulating water section, the circulating water heat exchange tube 13 is used for cooling; the low-temperature cooling In the water section, cooling is performed by the low-temperature cooling water heat exchange tube 14 .

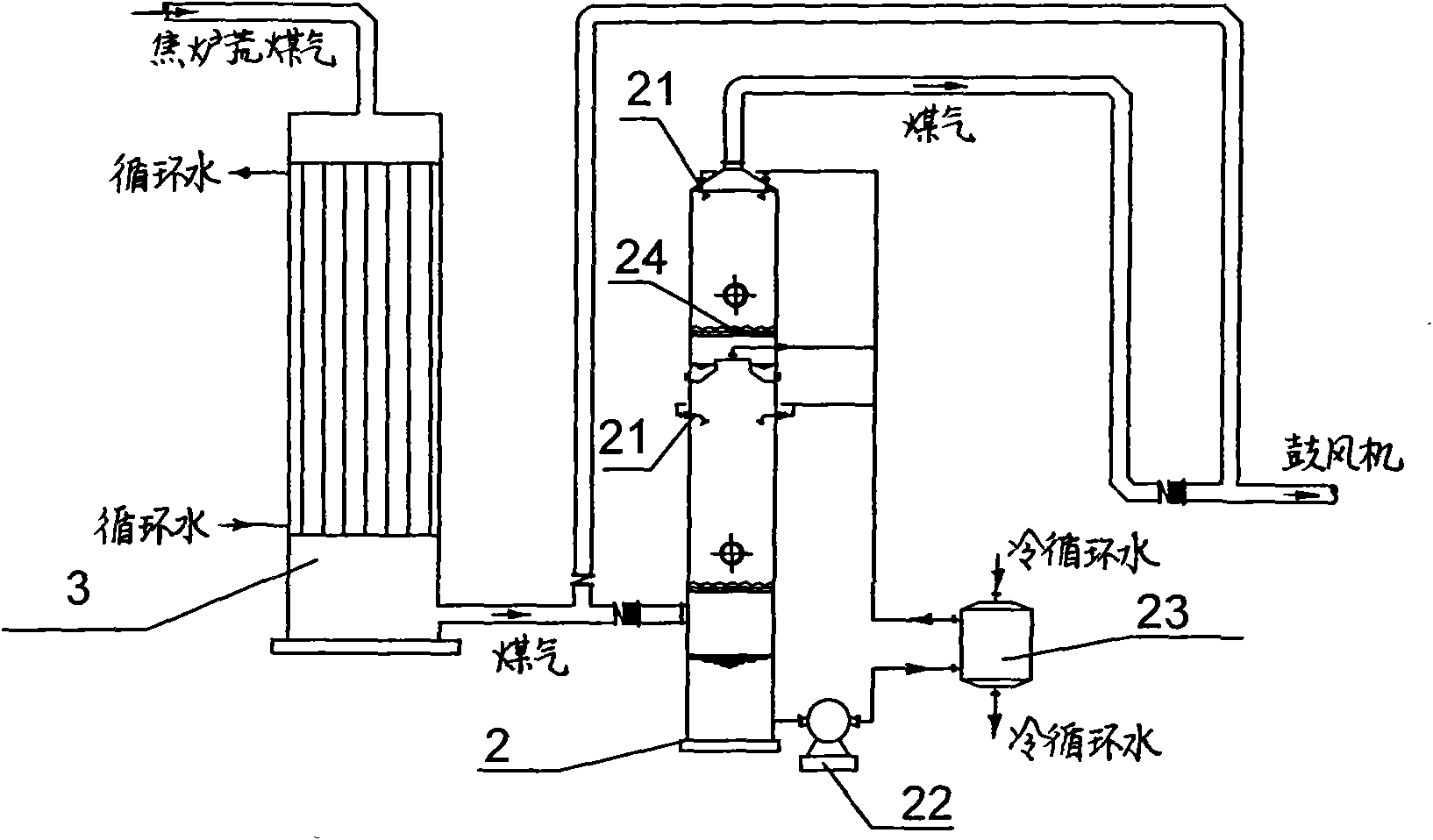

[0026] The bottom of the horizontal tube primary cooler is connected with the bottom of the direct cooling tower.

[0027] One or more ammonia water nozzles 21 are installed in the direct cooling tower, and the circulating ammonia water is sprayed into the direct cooling tower by the ammonia water nozzles, passes through the direct cooling tower circulation pump 22 at the bottom, is cooled by the spiral plate heat exchanger 23, and then sprayed through the ammonia water nozzles into the direct cooling towe...

Embodiment 2

[0036] Equipment is with embodiment 1.

[0037] The inlet water temperature of the circulating water section is controlled at 30-33°C, and the raw coal gas coming from the coke oven at 80-85°C is first cooled to 40-45°C through the circulating water section of the horizontal tube primary cooler;

[0038] The inlet water temperature of the low-temperature cooling water section is 16-18°C, and the raw coal gas of 40-45°C is cooled to 20-30°C through the low-temperature cooling water section.

[0039] The direction of circulating water and low-temperature cooling water is opposite to that of raw gas, which is countercurrent cooling.

[0040] Collect the condensate produced when the gas is cooled, and control its tar mass ratio at 3%, add it to the low-temperature cooling water section for spraying, and remove the naphthalene in the gas. Gas volume is 100000m 3 / h, gas condensate replenishment is 1.8m 3 / h. In this step, at least 90% of the naphthalene precipitated by gas cool...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com