Ultra-high strength steel hot stamping forming die

A technology of hot stamping and ultra-high strength, applied in the field of stamping molds, can solve the problems of inconvenient preparation, storage, and transportation of cooling gas, high scrap rate, complex mold structure, etc., to achieve easy daily maintenance and improve heat exchange efficiency , The effect of ensuring dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

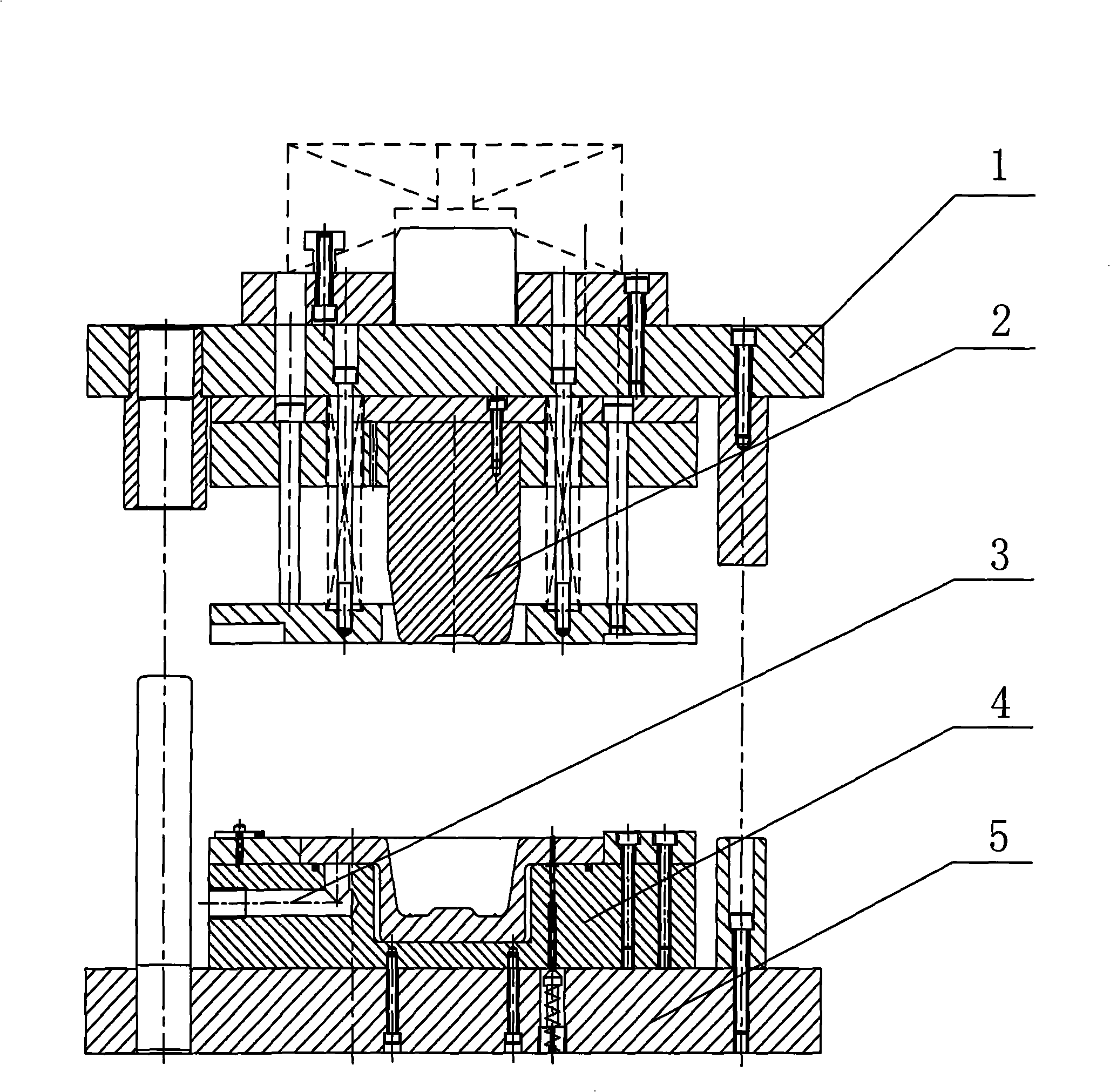

[0013] Such as figure 1 As shown, the punch 2 is fixed on the upper die base 1, the die 4 is fixed on the lower die base 5, the die 4 is provided with a cooling water channel 3, and the cooling water channel 3 is connected to a cooling water circulation system. During hot stamping, circulating cooling water is introduced into the cooling water channel arranged in the die to rapidly cool down the die to achieve the effect of solid quenching.

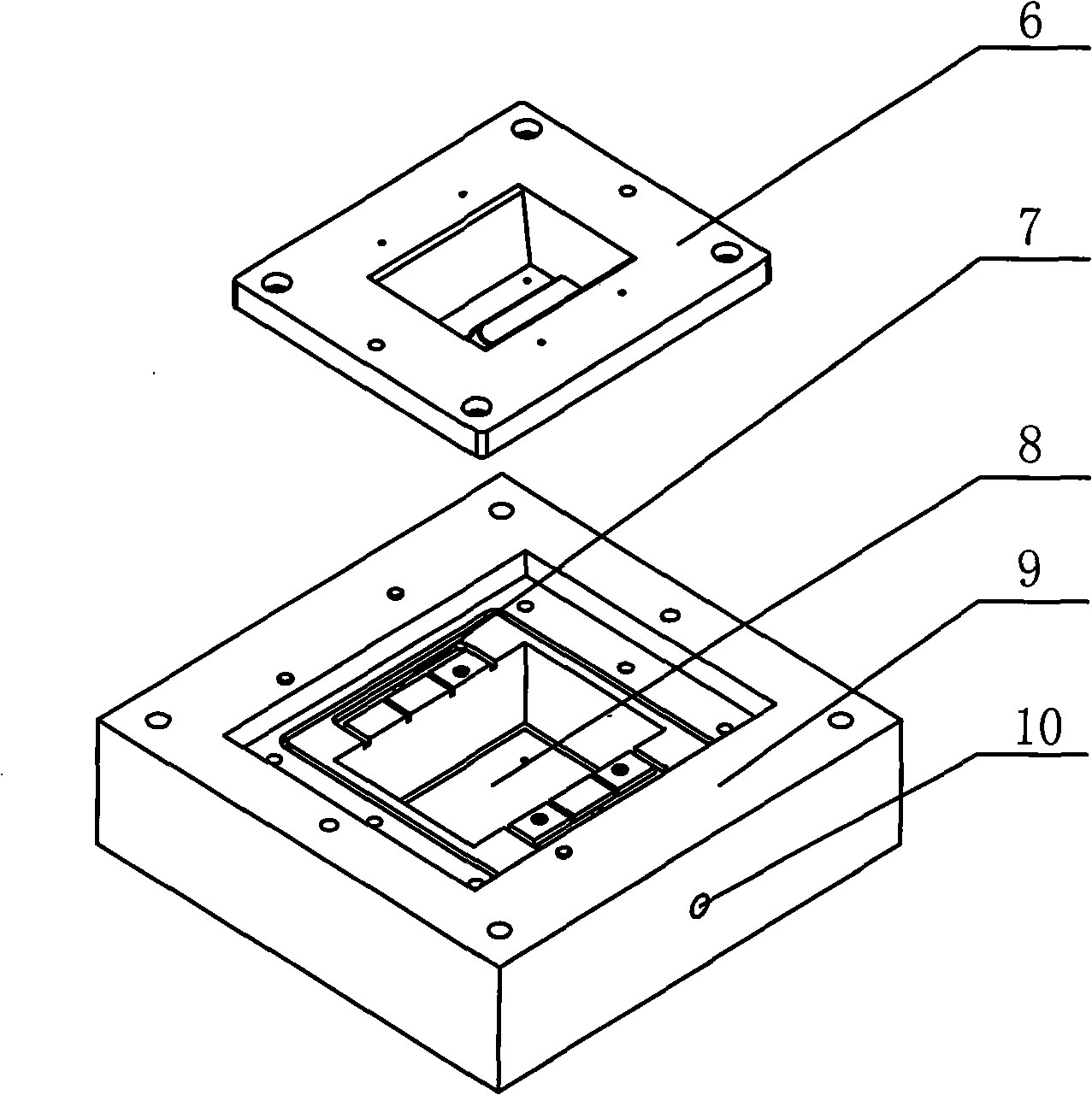

[0014] figure 2 Shown is a die structure of a preferred embodiment of the present invention, which uses a composite die, consisting of a groove-shaped die base 9 and a cavity body 6, the die base 9 is provided with a water inlet 7 and the water outlet 10, the cavity body 6 is located in the groove 8 of the die base 9, and there is a gap between the cavity body 6 and the die base 9, and the gap communicates with the water inlet 7 and the water outlet 10 . After passing through the cooling water, the space between the cavity body 6 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com