Method for controlling quality of bloom hypo-peritectic steel continuous casting billet

A technology of continuous casting slab and bloom, which is applied in the field of controlling the quality of bloom subperitectic steel continuous casting slab, which can solve the problems of easy surface depression, large linear shrinkage coefficient, and easy formation of air gap, etc., to achieve optimal performance, Improve cooling uniformity and reduce the effect of solidification phase transition shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

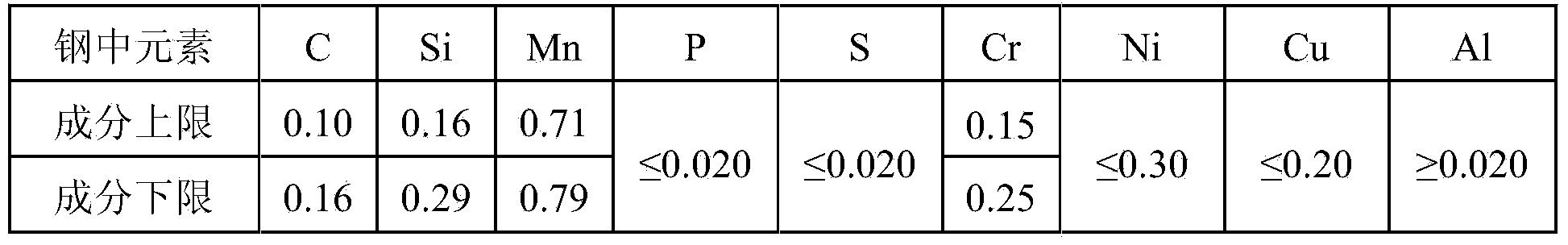

[0029] The following method is used to manufacture the continuous cast slab of hypoperitectic steel Q235D. Specifically, the smelting and continuous casting process adopted is as follows: firstly through ultra-high power electric arc furnace (UHP), ladle refining furnace (LF), vacuum degassing furnace (VD), and then through continuous casting of alloy steel with an arc radius of 11 meters The sub-peritectic steel Q235D continuous casting slab with a section of 260mm×300mm is produced by the machine. Table 2 shows the smelting chemical composition of the bloom hypoperitectic steel Q235D continuous casting slab of Example 1.

[0030] Table 2 Steel melting chemical composition of the bloom hypoperitectic steel Q235D continuous casting slab in Example 1 (wt%)

[0031]

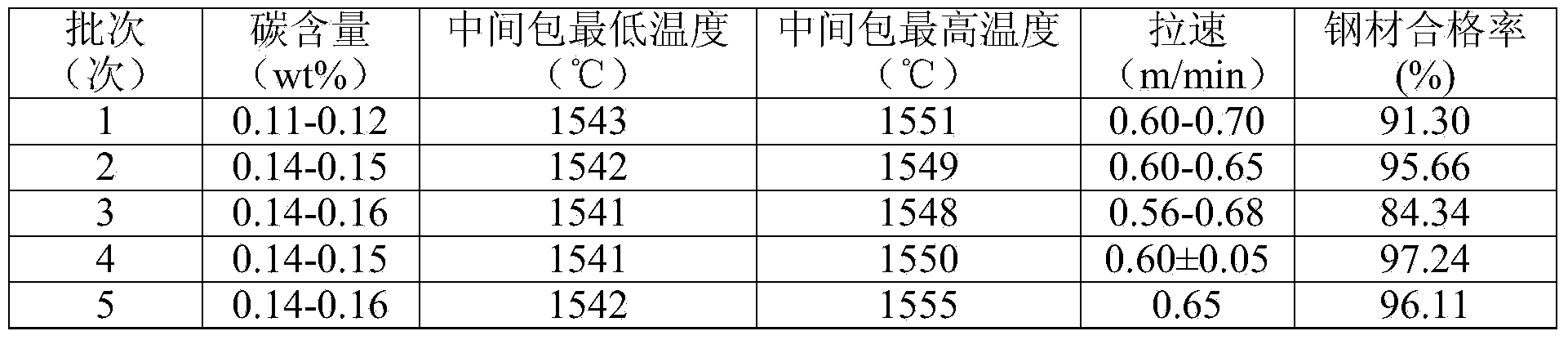

[0032] Calculate the carbon content C of the peritectic point according to the previous formula (2) J , and calculate the carbon content C of the peritectic point J The difference ΔC between the actual carbon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com