Control method of roll forming of twin-roll thin strip continuous casting cooling roll

A twin-roll thin strip continuous casting and control method technology, which is applied in the field of continuous casting technology and equipment in the metallurgical industry, can solve problems such as reducing the service life of cooling rolls, defects at the edge of the strip, and unfavorable rolling treatments, so as to prolong life, The effect of limited roll shape variation and good edge quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

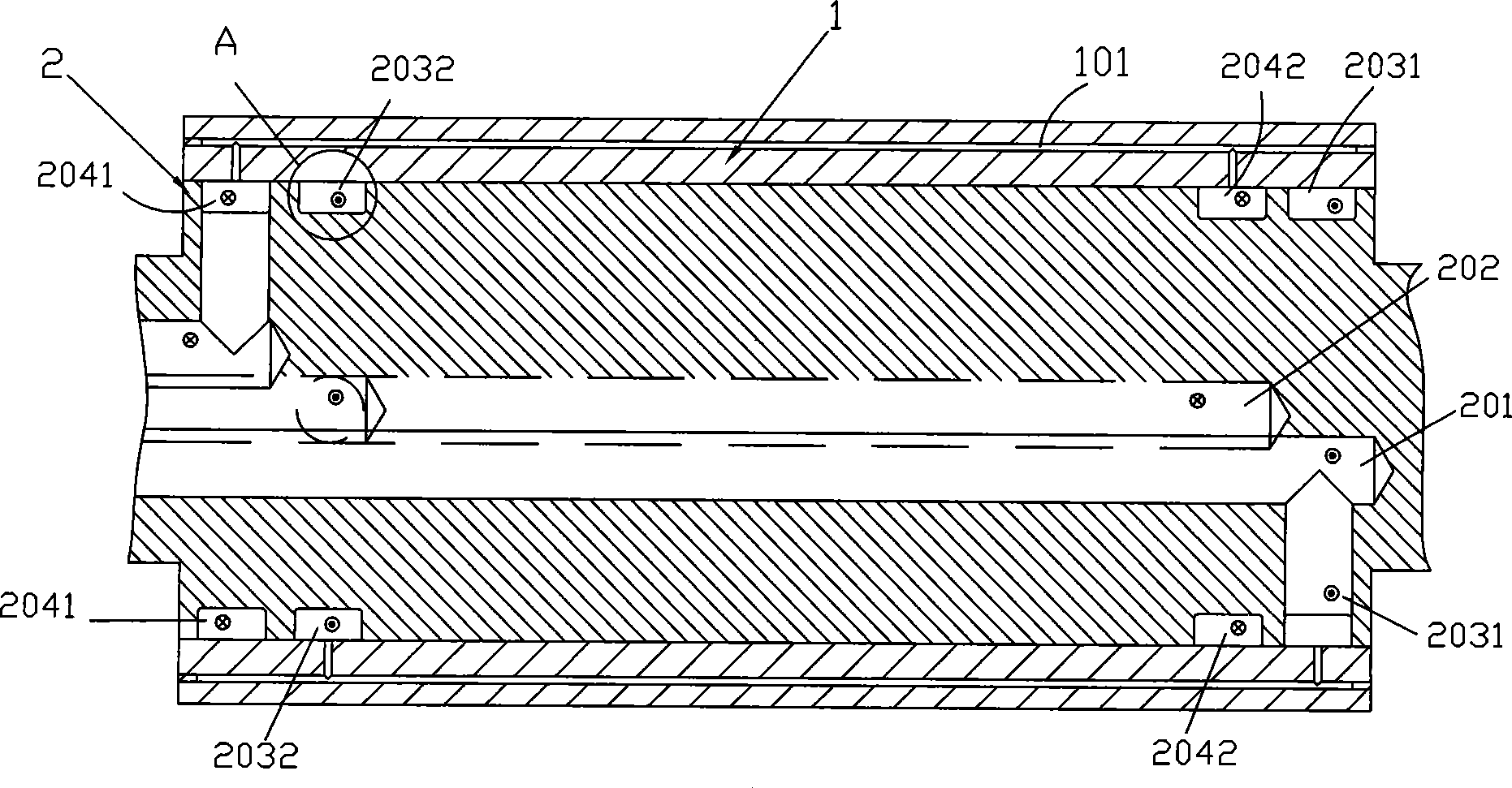

[0058] see image 3 , Figure 4 , which is an embodiment of the present invention. In this embodiment, two cooling rolls that pass through cooling water in relative rotation, including the roll sleeve 1 and the roll shaft 2, are shrink-fitted together, and the roll sleeve 1 adopts Made of special materials, it has good thermal conductivity and resistance to shock and heat; the roller shaft 2 is made of high-strength structural steel, and the shape of the cooling roller is a cylindrical flat roller. A water channel 101, a water inlet channel 201 and a water outlet channel 202 are opened in the axial direction of the roller shaft 2, and two cooling water channels corresponding to the water inlet and outlet channels 201, 202 and the roller sleeve 1 are respectively opened on both sides of the outer periphery 101 is connected to the water inlet water collection ring groove 2031, 2041 and the water outlet water collection ring groove 2032, 2042; the inner peripheral edge of the ro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com