Method for producing high-strength thin strip steel in short process

A high-strength, thin-strip technology, applied in workpiece surface treatment equipment, metal processing equipment, metal rolling, etc., can solve problems such as uneven cooling, limited cooling speed, and affecting surface quality, so as to improve cooling uniformity and Cooling speed, maintaining excellent performance, and improving the effect of process space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

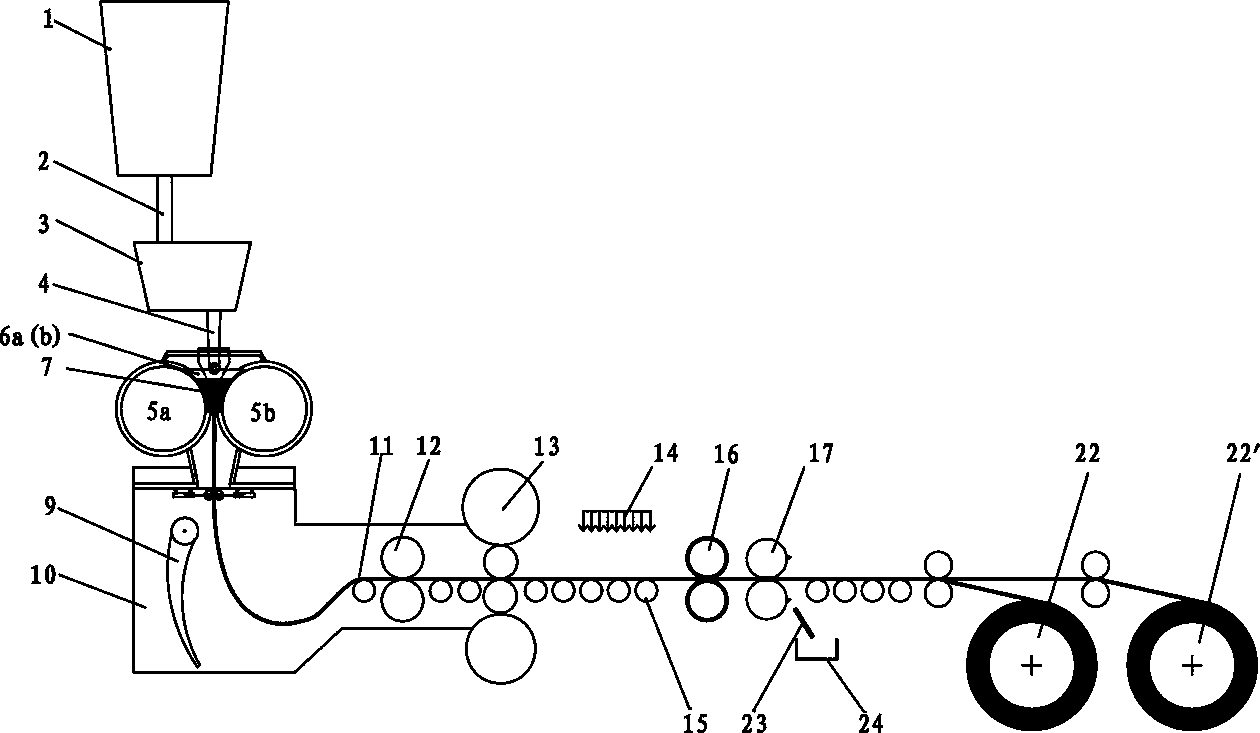

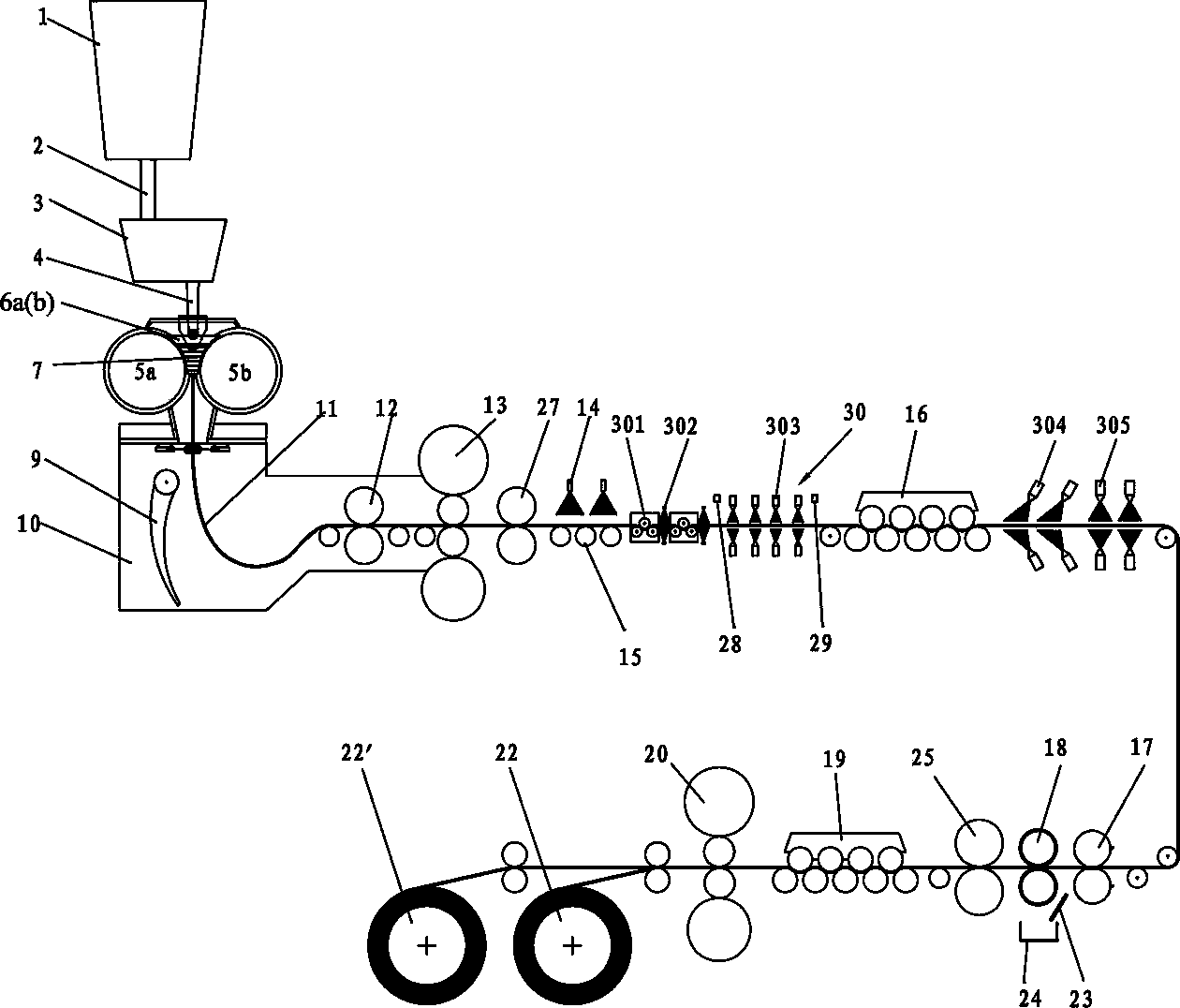

[0054] Such as figure 2 , Figure 4 Shown, the short flow process of the present invention produces a kind of atmospheric corrosion resistant steel strip, and it comprises the steps:

[0055] a) Smelting and casting

[0056] The mass percentage of chemical composition of steel strip is: C 0.02~0.15%, Si 0.20~0.6%, Mn0.2~1.5%, P 0.02~0.3%, S≤0.006%, Cu 0.3~0.80%, Nb 0.010-0.025%, Ti 0.01-0.03%, Al 0.01%-0.06%, Cr 0.40-0.8%, Ni 0.08-0.40%, Re 0.02-0.25%; the rest is Fe and unavoidable impurities; twin-roll thin strip continuous casting, ladle 1 The molten steel in the molten steel is poured directly into a molten pool 7 surrounded by two relatively rotating casting rolls 5a, 5b capable of rapid cooling and side sealing devices 6a, 6b through the nozzle 2, tundish 3 and flow distributor 4, The molten steel solidifies on the rotating circumferential surface of the casting rolls, and then forms a solidified shell and gradually grows, and then forms a 1.5mm thick casting belt 11...

Embodiment 2

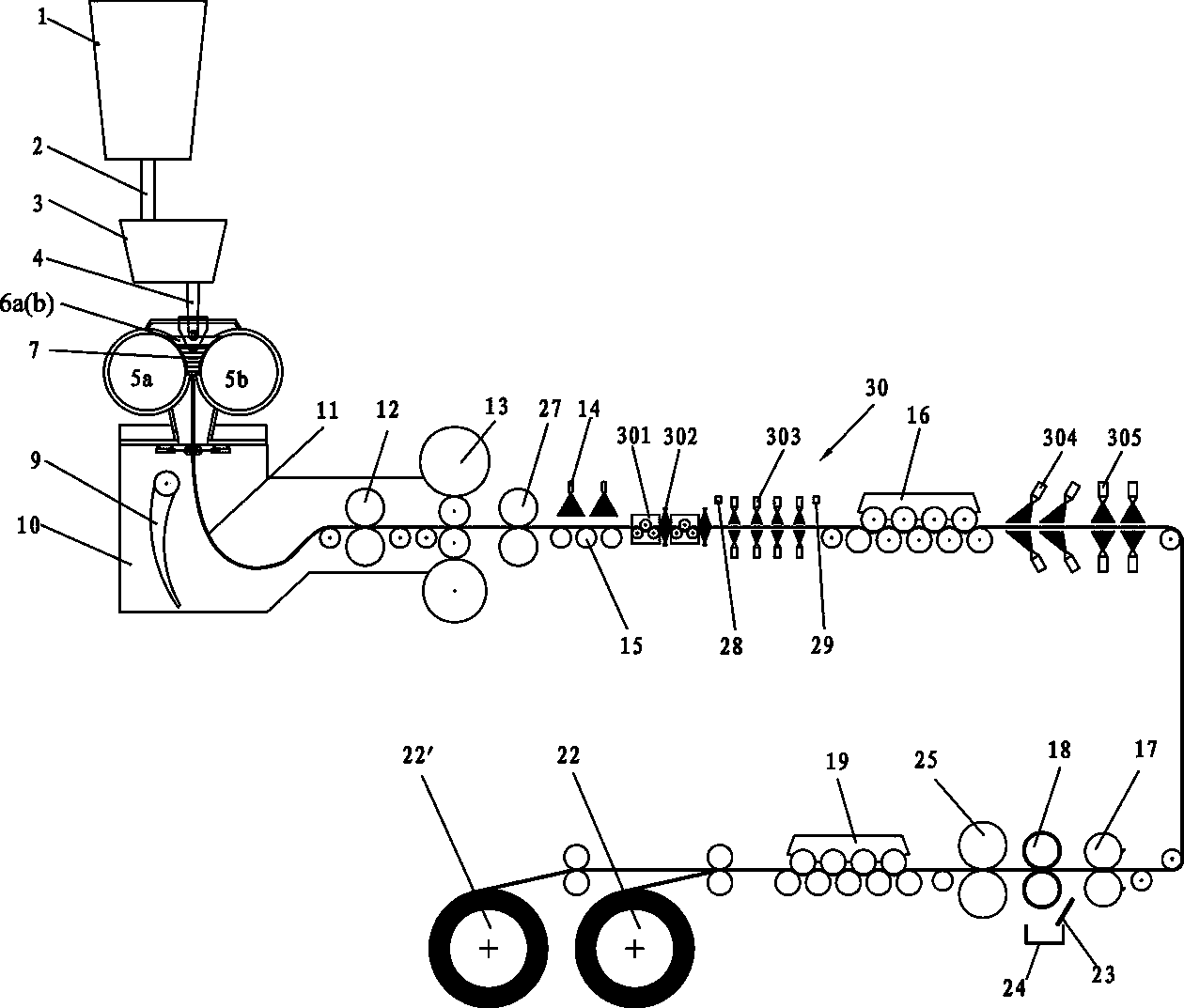

[0080] see image 3 , which shows another embodiment of the present invention, the steel type and most of the production process are the same as in embodiment 1, except that no smoothing treatment is carried out before entering the coiler, the thickness is 1.6mm, and the surface roughness Ra<2.5μm .

[0081] In summary, the present invention adopts the method of atomization cooling + rapid anti-oxidation cooling in the cooling stage of thin strip continuous casting strip steel by combining the acid-free dephosphorization process to improve cooling uniformity and cooling speed; the anti-oxidation cooling method can control The thickness of the oxide skin on the surface of the strip is beneficial to the subsequent rapid jet dephosphorization; in the jet fine dephosphorization process, the combination of fine dephosphorization particles and liquid medium is used to improve the surface quality of the strip, that is: the dephosphorization process and the enhanced cooling of the str...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com