Device and method for rapid preparation of ice particle gas jet

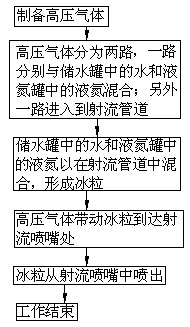

A technology of gas jet and preparation device, which is applied in the direction of abrasive feeding device, used abrasive processing device, manufacturing tools, etc., which can solve the problem of the inability to realize the integration of ice particle preparation and jet flow, and the inability to realize the continuous preparation of ice particles , Ice particles continue to be in the low temperature field, etc., to achieve simple and rapid preparation, easy control, and convenient effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

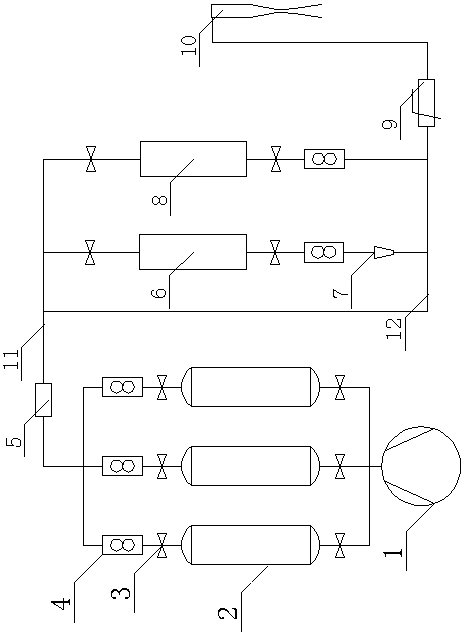

[0028] A device for rapid preparation of ice particle gas jet, such as figure 1 As shown, it includes a high-pressure gas section, which is used to prepare gas with pressure. The high-pressure gas section includes an air compressor 1, a gas input pipeline 11 and at least one gas cylinder 2. The number of gas cylinders 2 in this embodiment is 3. In order to facilitate the control of the gas, a valve 3 is provided on the gas inlet and the gas outlet of the gas cylinder 2, and the control process of gas transmission is facilitated by opening or closing the valve 3. At the same time, a flow meter 4 is arranged on the gas outlet of the gas cylinder 2, and the flow rate of the gas coming out of each gas cylinder can be known through the flow meter 4. By monitoring the gas parameters, the flow rate of the entire ice particle gas jet can be monitored in time. Make adjustments to the process to ensure its efficient working status. The air compressor 1 is connected to the gas inlet of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com