Strong wind cooling system for medium plate heat treatment

A strong wind cooling and air supply system technology, applied to heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve the problems of low overall control of the cooling process, precise cooling strategies and cooling procedures, and the inability to achieve regional cooling, etc., to achieve Reduce jet backflow and jet interference, eliminate blind spots and eddy currents, and improve cooling uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

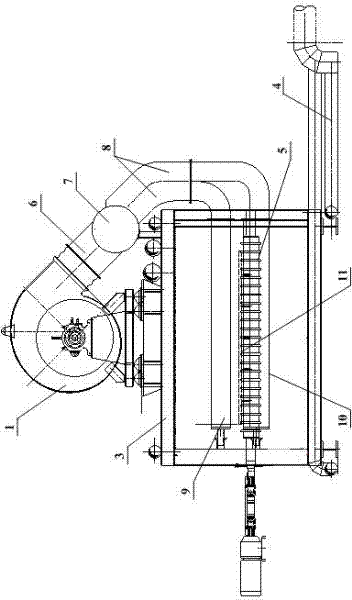

[0029] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0030] Firstly, an embodiment of the forced wind cooling device of the present invention will be described below.

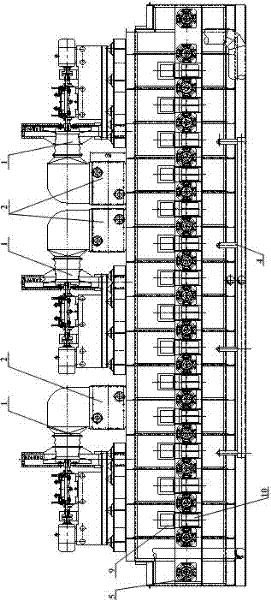

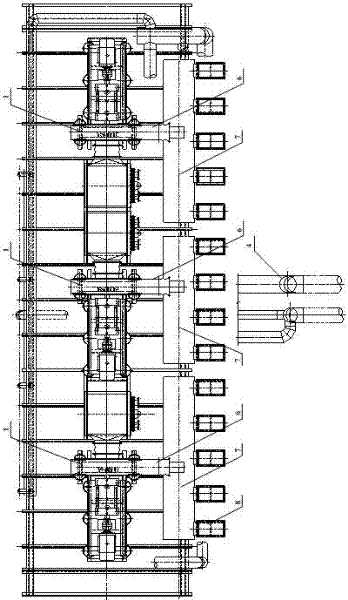

[0031] The cooling room of the strong wind cooling system is divided into multiple cooling sections, each cooling section contains several upper and lower spray boxes and several roller tables, the steel plate moves at the process speed on the roller surface between the upper and lower spray boxes, and the roller table is controlled by independent transmission , Frequency conversion in groups. Each cooling section is equipped with a set of air supply system, a set of heat exchanger and a set of control system. A water wall composed of cooling water pipes is installed in the side wall and top wall of the cooling chamber. Its function is to increase the cooling speed of the steel plate and prevent the heat transfer of the steel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com