High-efficient conductive fibre and preparing method thereof

A conductive fiber, high-efficiency technology, applied in the manufacture of conductive/antistatic filaments, single-component polyester rayon, etc., can solve the problems of poor dispersion of conductive powder, general spinnability, and good conductive effect. The effect of low manufacturing cost, good spinnability and excellent electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

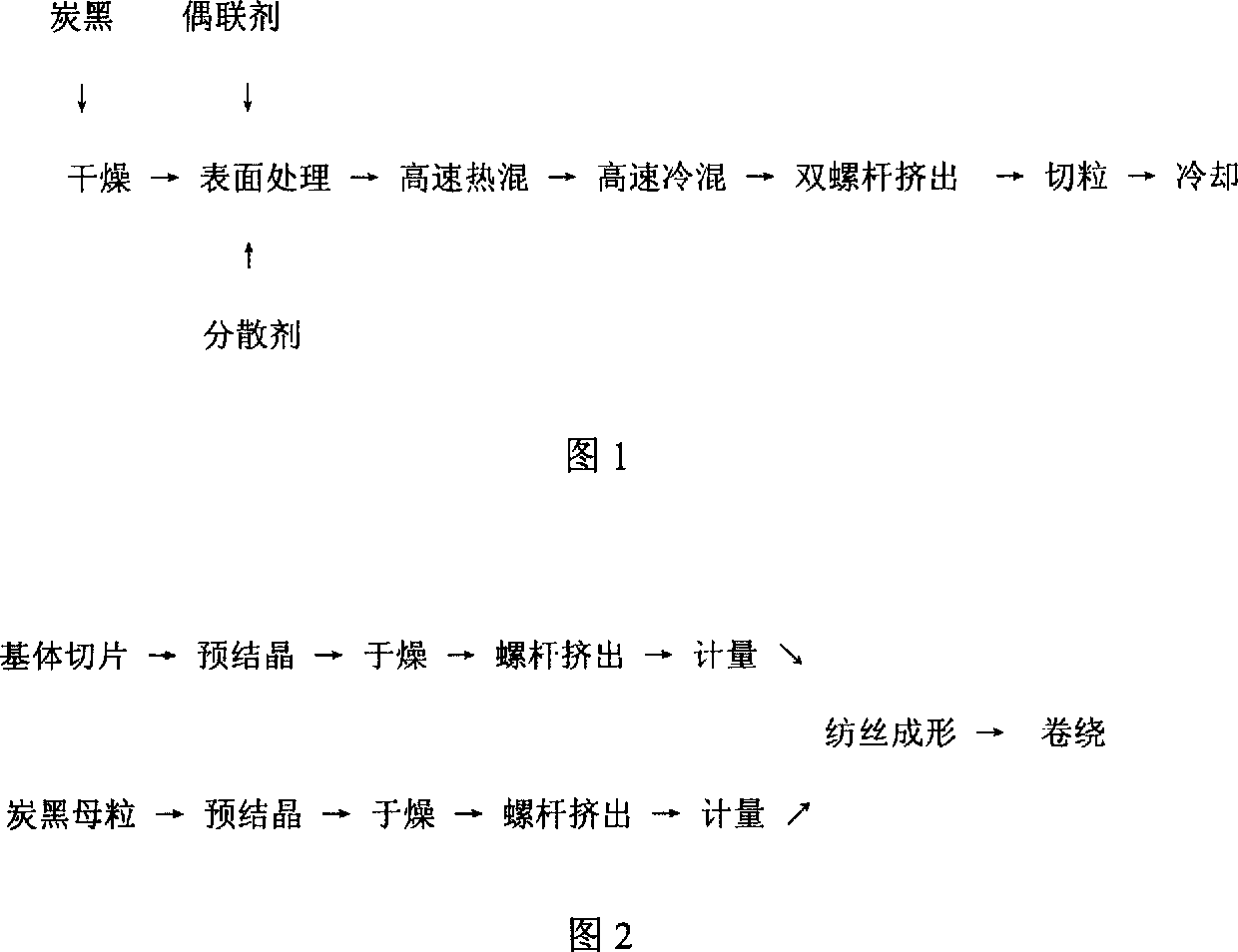

[0014] The present invention will be further described below with reference to the embodiments and accompanying drawings. The preparation method of this special effect conductive fiber, its main steps are as follows:

[0015] (1) Masterbatch preparation:

[0016] Dry 500 grams of conductive carbon black at 95°C, put the dried carbon black into a high-speed mixer, add 3% coupling agent (CT-928) by spraying, and heat to 125°C , after high-speed stirring for 25 minutes, add dispersant respectively: polyethylene wax (2000) 10%; antioxidant: 1010 1.5%; DLTP 1.5%; magnesium stearate 3%; The ester powder was mixed at high speed for 15 minutes, and then cold mixed at high speed for 15 minutes before discharging. Put the above materials into the hopper of twin-screw extruder for twin-screw extruder, extrusion and granulation.

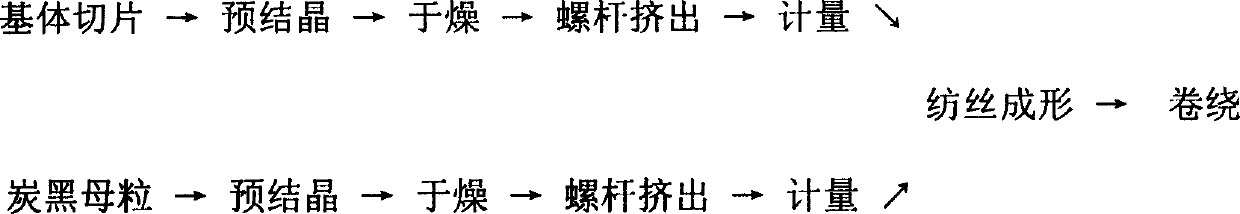

[0017] Its technological process (as shown in Figure 1):

[0018] Extrusion temperature: (℃)

[0019] Zone 1 Zone 2 Zone 3 Zone 4 Zone 5 Zone 6

[0020] 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com