Bamboo charcoal viscose filament and its making method

A technology of viscose filament and bamboo carbon viscose, which is applied in the direction of rayon manufacturing, filament/thread molding, single-component cellulose rayon, etc., can solve the problem of urgent increase in technical content and special functions, single function, Problems such as additional functions and value not being brought into play, to achieve the effect of satisfying health and environmental protection, increasing functional value, and enhancing product added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

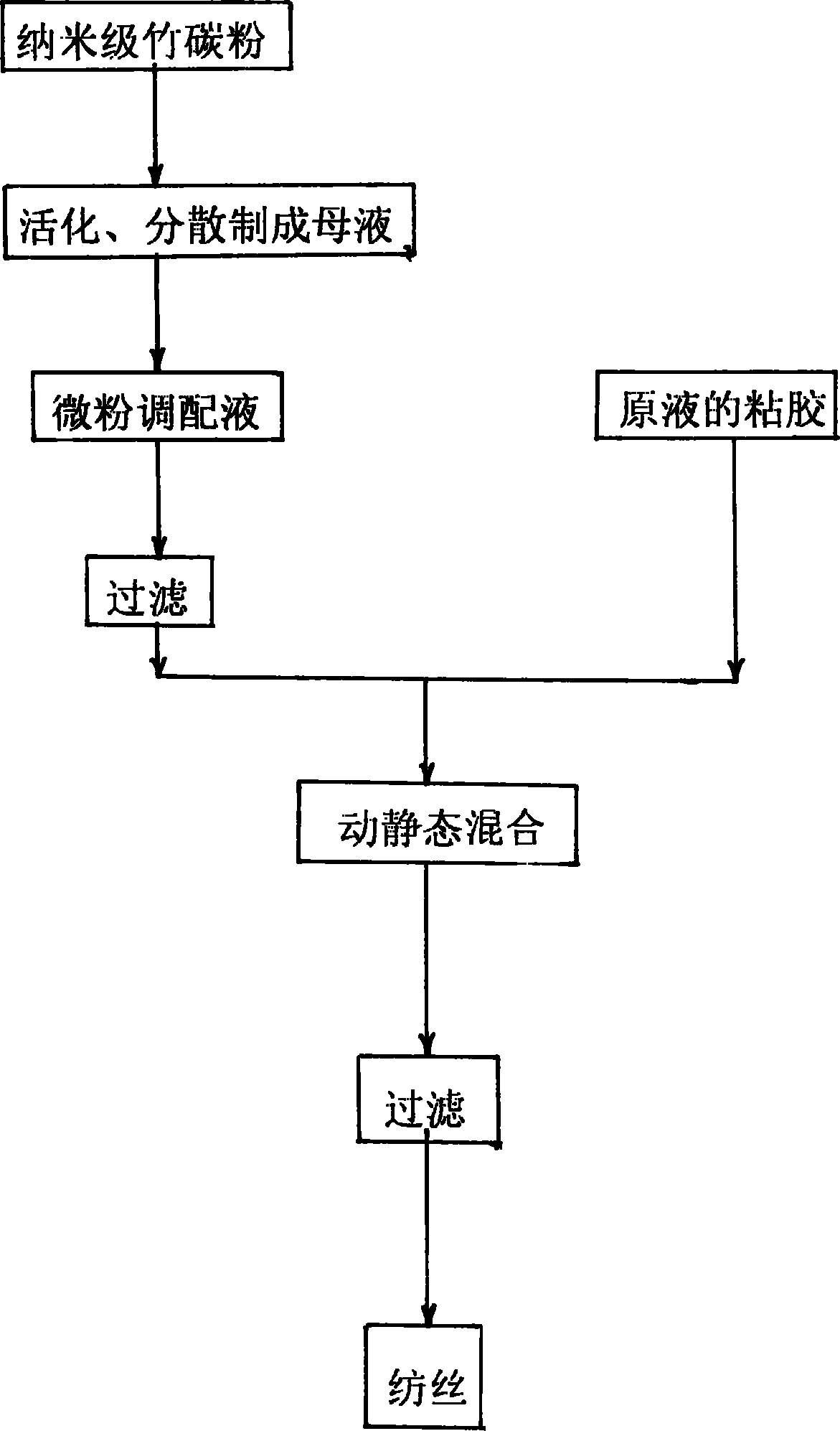

Image

Examples

Embodiment 1

[0030] Bamboo carbon viscose filament, described bamboo carbon viscose filament refers to that bamboo carbon powder solution and viscose solution are mixed by 0.1% and then spun to obtain 30 single filaments and 0% deviation of single filaments , the residual sulfur content is 4.8mg / 100g, the oil content is 0.35%, the dyeing uniformity is 3.5, and the finished product of bamboo carbon viscose filament is 99.8% resistant to Escherichia coli and Staphylococcus aureus. The bamboo carbon powder refers to a nano-scale black powder made of bamboo as a raw material, which is fired by high-temperature carbonization technology at 1600° C., activated, refined and ground.

[0031] The manufacture method of bamboo carbon viscose filament, is to realize according to the following steps:

[0032] A, the preparation of bamboo carbon powder mother liquor: by powder: the ratio of water=1: 1.5, dispersant addition adds by making 0.5% of mother liquor, and its concrete steps are:

[0033] (1), ...

Embodiment 2

[0047] Bamboo charcoal viscose filament, described bamboo charcoal viscose filament refers to that bamboo carbon powder solution and viscose solution are mixed by 2% and then spun to obtain 30 single filaments and 0% deviation of single filaments , the residual sulfur content is 4.8mg / 100g, the oil content is 0.35%, the dyeing uniformity is 3.5, and the finished product of bamboo carbon viscose filament is 99.8% resistant to Escherichia coli and Staphylococcus aureus. The bamboo carbon powder refers to a nano-scale black powder made of bamboo as a raw material, which is fired by high-temperature carbonization technology at 1600° C., activated, refined and ground.

[0048] The manufacture method of bamboo carbon viscose filament, is to realize according to the following steps:

[0049]A, the preparation of bamboo charcoal powder mother liquor: by powder: the ratio of water=1:5, dispersant add-on adds by making 3% of mother liquor, and its concrete steps are:

[0050] (1), firs...

Embodiment 3

[0064] Bamboo charcoal viscose filament, described bamboo charcoal viscose filament refers to that bamboo carbon powder solution and viscose solution are mixed by 1% and then spun to obtain 30 single filaments and 0% deviation of single filaments , the residual sulfur content is 4.8mg / 100g, the oil content is 0.35%, the dyeing uniformity is 3.5, and the finished product of bamboo carbon viscose filament is 99.8% resistant to Escherichia coli and Staphylococcus aureus. The bamboo carbon powder refers to a nano-scale black powder made of bamboo as a raw material, which is fired by high-temperature carbonization technology at 1600° C., activated, refined and ground.

[0065] The manufacture method of bamboo carbon viscose filament, is to realize according to the following steps:

[0066] A, the preparation of bamboo carbon powder mother liquor: by powder: the ratio of water=1: 3, dispersant addition adds by making 1.5% of mother liquor, and its concrete steps are:

[0067] (1), ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com