Melt direct spinning superfine denier terylene FDY filament and preparation process thereof

A technology of ultra-fine denier polyester and melt direct spinning, which is applied in the directions of melt spinning, filament forming treatment, filament/thread forming, etc. The effect of reduced energy consumption, improved intrinsic quality, and reduced processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

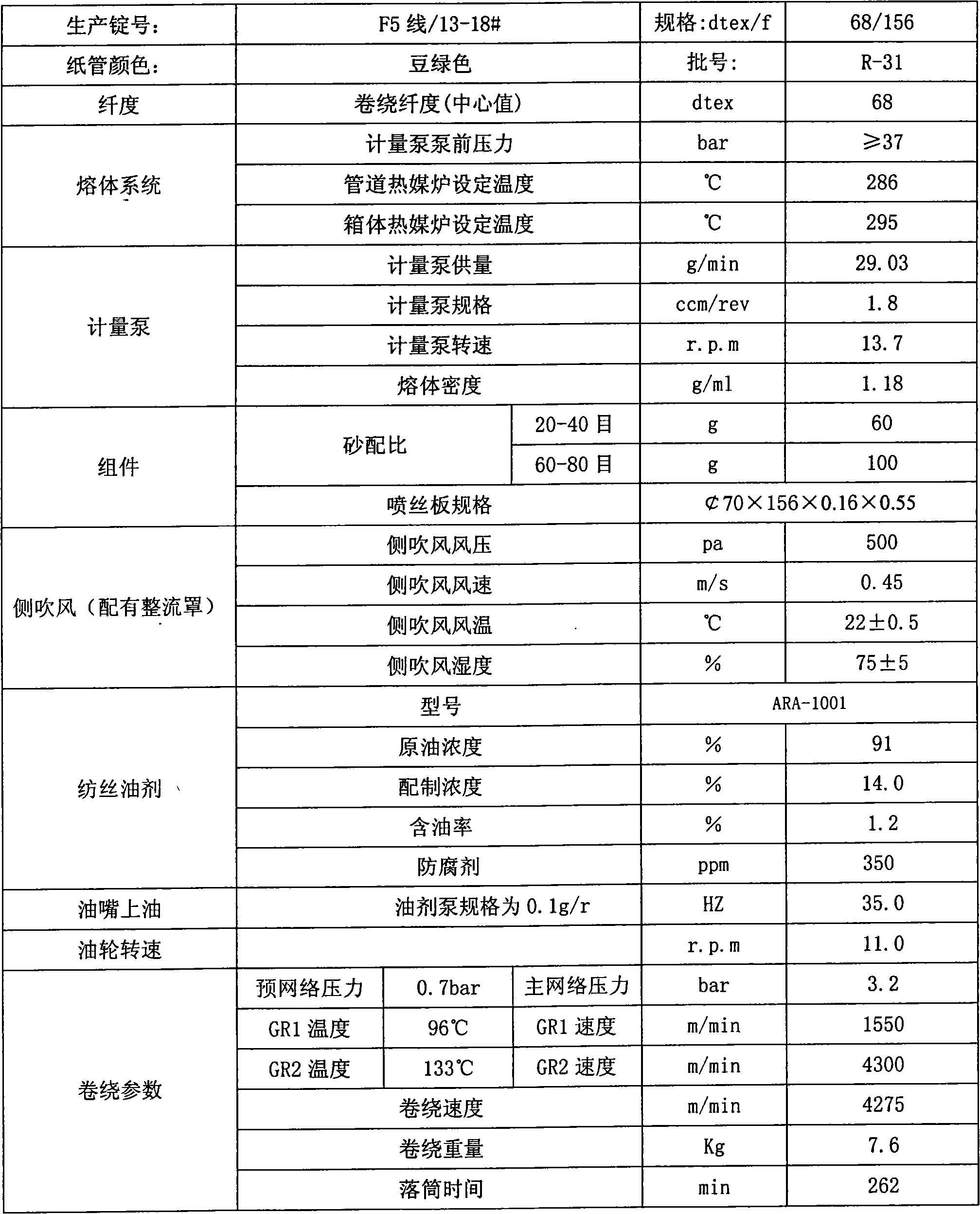

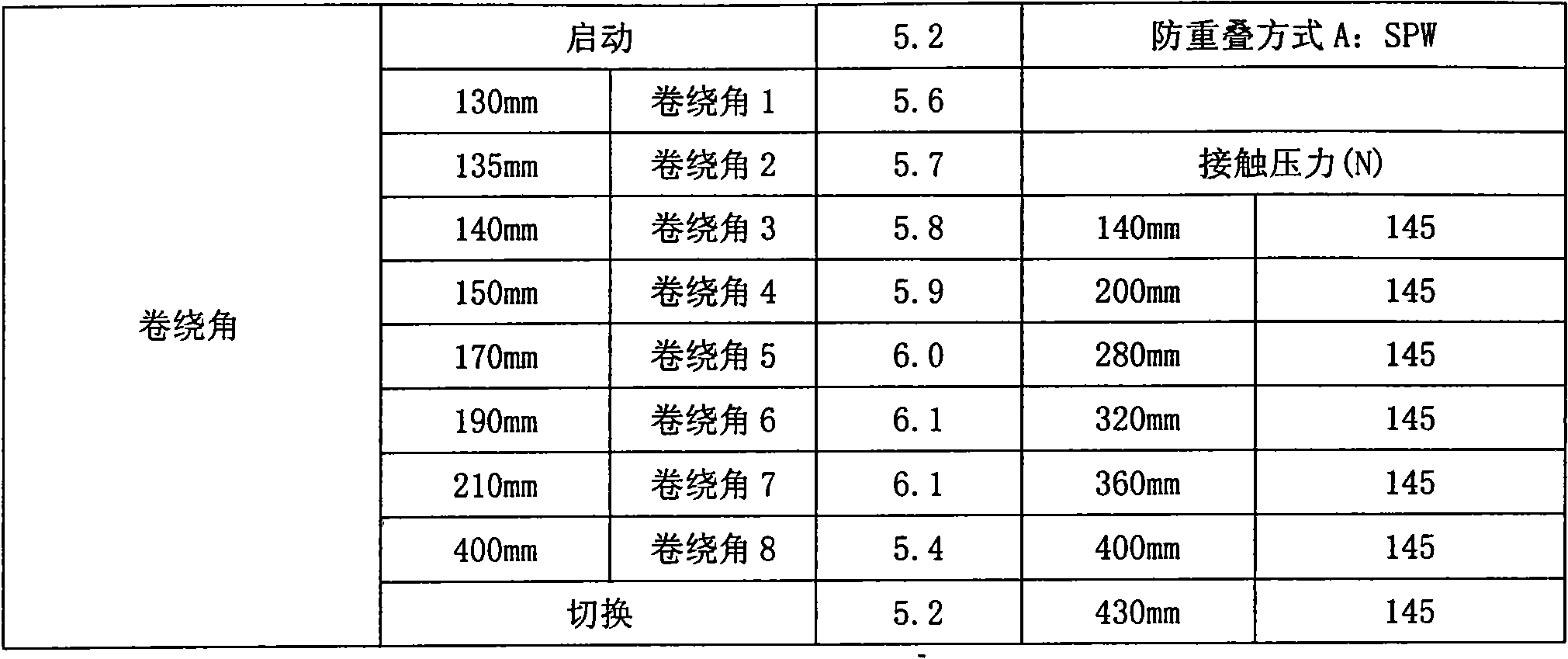

[0018] Embodiment 1 produces the FDY silk (single-filament fineness dpf is 0.436) that specification is 68dtex / 156F.

[0019] This product adopts the one-step production route of melt direct spinning. The polyester melt (PET) obtained by PTA+EG polymerization passes through the melt filter, then is boosted and transported by the gear booster pump, cooled by the cooler, and then distributed to each spinning machine. Each spinning position sends the melt to each spinning assembly quantitatively by a metering pump. After the melt is filtered and uniformly pressurized through the filter layer in the spinning assembly, it passes through the capillary-shaped spinneret hole (the spinneret is in the spinning In the assembly, the capillary diameter of the plate is 0.16mm, L / D=3.4, and the diameter of the plate surface is 70mm.) It is sprayed out in a thin stream, and a fairing is installed in the primary fiber cooling area, and the melt stream passes through the cooling area After bein...

Embodiment 2

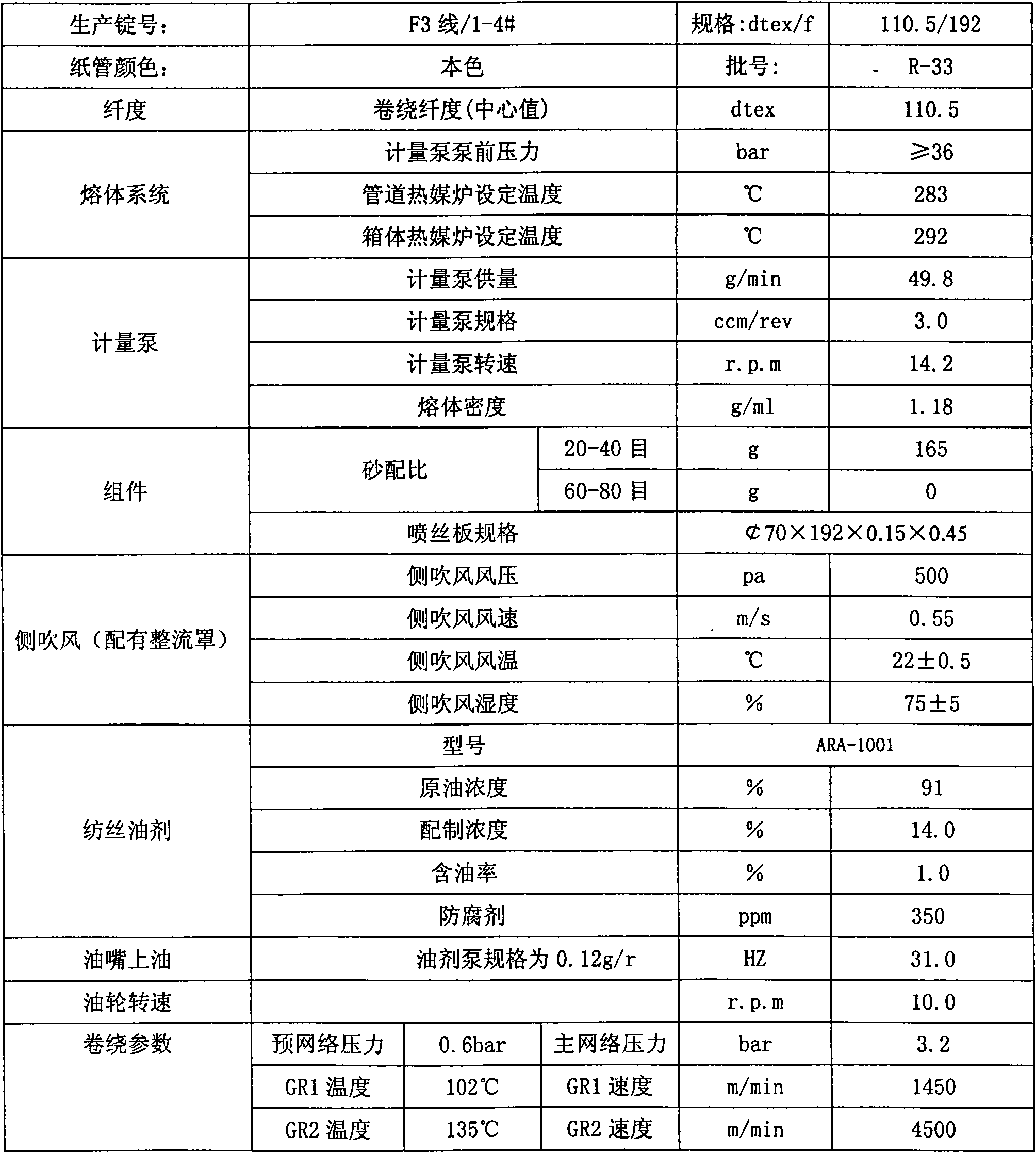

[0027] Example 2 produces FDY yarns with specifications of 110.5dtex / 192F (single yarn fineness dpf is 0.576).

[0028] This product adopts the one-step production route of melt direct spinning. The polyester melt (PET) obtained by PTA+EG polymerization passes through the melt filter, then is boosted and transported by the gear booster pump, cooled by the cooler, and then distributed to each spinning machine. each spinning position, the melt is quantitatively sent to each spinning assembly by a metering pump, and the melt is filtered and uniformly pressurized through the filter layer in the spinning assembly, and then passes through the capillary-shaped spinneret hole (the spinneret is in the spinning In the assembly, the capillary diameter of the plate is 0.15mm, L / D=3, and the diameter of the plate surface is 70mm.) It is sprayed out in a thin stream, and a fairing is installed in the primary fiber cooling area, and the melt stream passes through the cooling area After being...

Embodiment 3

[0036] Embodiment 3 production specification is the FDY silk (single filament denier dpf is 0.385) of 55.5dtex / 144F

[0037] This product adopts the one-step production route of melt direct spinning. The polyester melt (PET) obtained by PTA+EG polymerization passes through the melt filter, then is boosted and transported by the gear booster pump, cooled by the cooler, and then distributed to each spinning machine. Each spinning position sends the melt to each spinning assembly quantitatively by a metering pump. After the melt is filtered and uniformly pressurized through the filter layer in the spinning assembly, it passes through the capillary-shaped spinneret hole (the spinneret is in the spinning In the assembly, the capillary diameter of the plate is 0.15mm, L / D=2.7, and the diameter of the plate surface is 90mm.) It is sprayed out in a thin stream, and a fairing is installed in the primary fiber cooling area, and the melt stream passes through the cooling area After being...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com