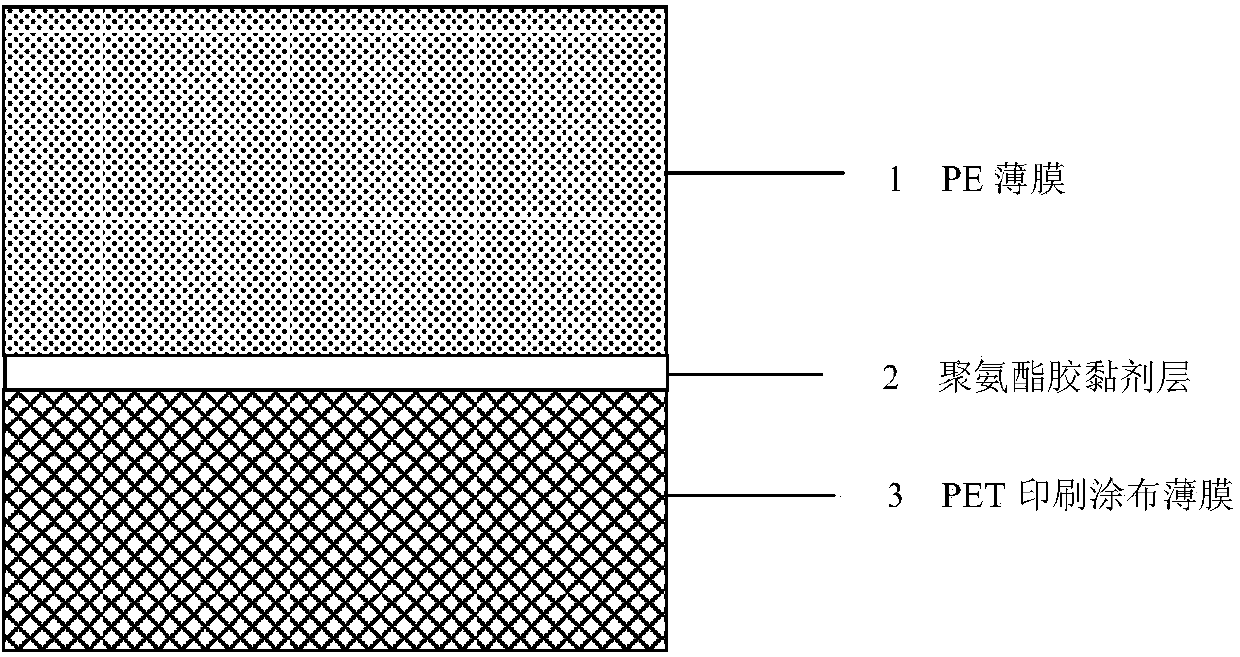

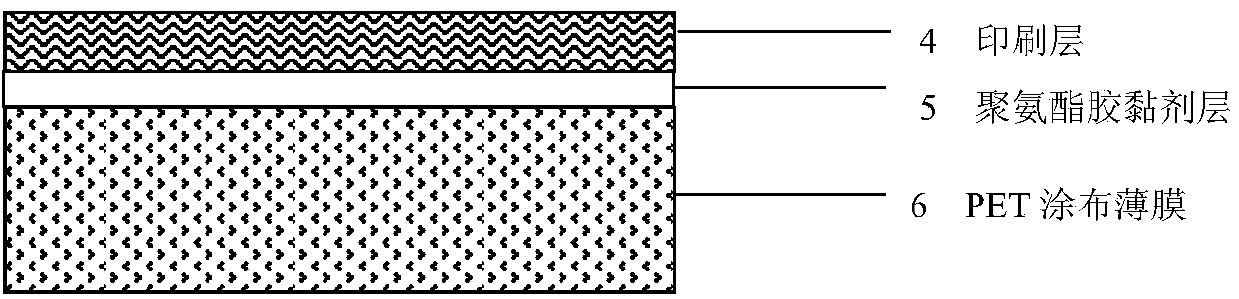

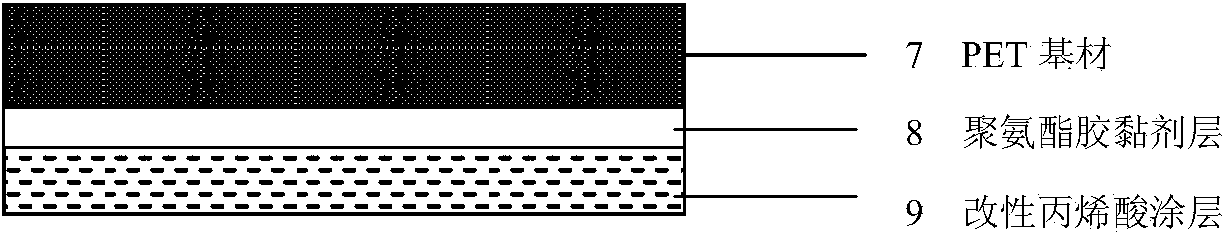

Composite film for flour packaging and manufacturing method thereof

A manufacturing method and composite film technology, applied in packaging, wrapping paper, transportation and packaging, etc., can solve problems such as large amount of addition, influence on emulsion stability, emulsion breaking, etc., achieve good heat sealing performance, and simple and easy production process control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Manufacture raw material (weight percentage) according to following composition:

[0040]

[0041]

[0042] (1) Preparation of modified acrylic emulsion:

[0043] Add 0.51kg of sodium lauryl sulfate, 0.51kg of OP-10 and 0.3kg of potassium persulfate into the pre-emulsification tank in sequence, then add 250kg of deionized water, start stirring to fully dissolve the contents of the tank; Process ratio Add 60kg of acrylic acid, 80kg of ethyl acrylate, 40kg of methyl acrylate and 40kg of methyl methacrylate into the polymerization kettle in sequence, stir and emulsify for 15 minutes to obtain a pre-emulsion, and heat up to 70°C under nitrogen protection; in the polymerization kettle Add 1.5kg sodium lauryl sulfate, 1.5kg OP-10, 0.7kg potassium persulfate and 500kg deionized water in sequence; stir and heat up to 80°C, add 1kg of silicone defoamer, keep the temperature for 5 minutes, Use the installed plunger pump to slowly inject the contents of the pre-emulsificati...

Embodiment 2

[0049] Manufacture raw material (weight percentage) according to following composition:

[0050]

[0051] (1) Preparation of modified acrylic emulsion:

[0052] Add 0.1kg sodium lauryl sulfate, 0.2kg OP-10 and 0.05kg ammonium persulfate in turn into the pre-emulsification kettle, then add 44kg deionized water, start stirring to fully dissolve the contents of the kettle; according to the set specific Proportion of process Add 18.2kg of acrylic acid, 24kg of butyl acrylate, 8kg of methyl acrylate and 8kg of methyl methacrylate into the polymerization kettle in sequence, stir and emulsify for 20 minutes to obtain a pre-emulsion, and heat up to 70°C under nitrogen protection; Add 0.3kg of sodium lauryl sulfate, 0.4kg of OP-10, 0.15kg of ammonium persulfate and 90kg of deionized water in sequence; stir and heat up to 80°C, add 0.36kg of silicone defoamer, and keep the temperature constant for 5 minutes Finally, use the installed plunger pump to slowly inject the contents of the...

Embodiment 3

[0058] Manufacture raw material (weight percentage) according to following composition:

[0059]

[0060] (1) Preparation of modified acrylic emulsion:

[0061] Add 0.52kg of sodium lauryl sulfate, 0.52kg of OP-10 and 0.3kg of potassium persulfate to the pre-emulsification kettle in sequence, then add 230kg of deionized water, and start stirring to fully dissolve the contents of the kettle; Process ratio Add 100kg of acrylic acid, 80kg of ethyl acrylate, 30kg of methyl acrylate and 30kg of methyl methacrylate into the polymerization tank in sequence, stir and emulsify for 30 minutes to obtain a pre-emulsion, and heat up to 75°C under nitrogen protection; in the polymerization tank Add 0.52kg sodium lauryl sulfate, 0.52kg OP-10, 0.7kg potassium persulfate and 500kg deionized water in sequence; stir and heat up to 80°C, add 2kg of silicone defoamer, keep the temperature for 5 minutes, Use the installed plunger pump to slowly inject the contents of the pre-emulsification tank...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com