Material adopting thin graphene and metal powder composite structure, preparation method and application thereof

A technology of thin-layer graphene and metal powder, applied in the direction of non-metal elements, chemical instruments and methods, carbon compounds, etc., can solve the problems of easy oxidation or corrosion, high cost of metal powder, active chemical properties, etc., to achieve Enhance oxidation resistance and corrosion resistance, reduce system cost and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

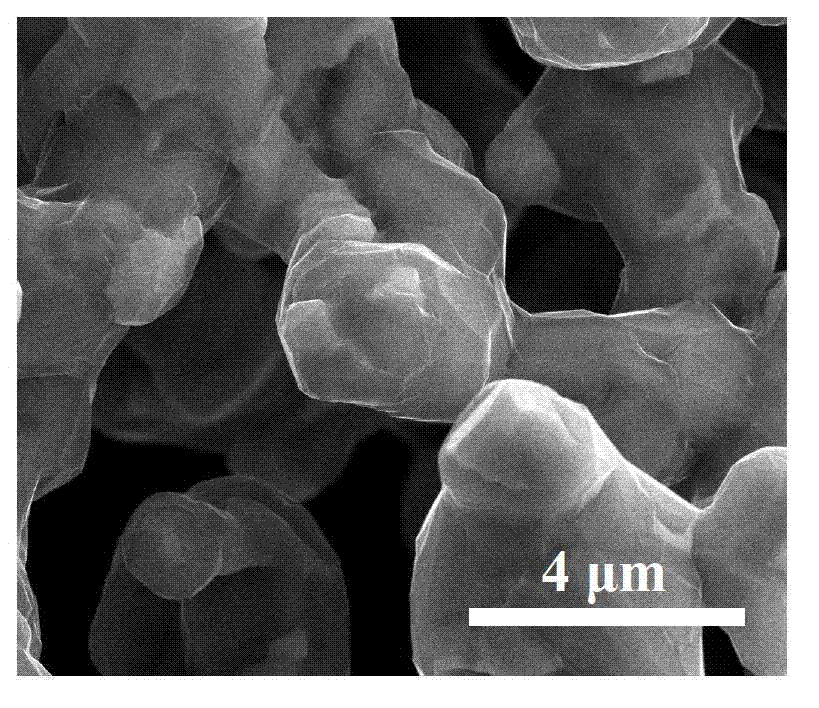

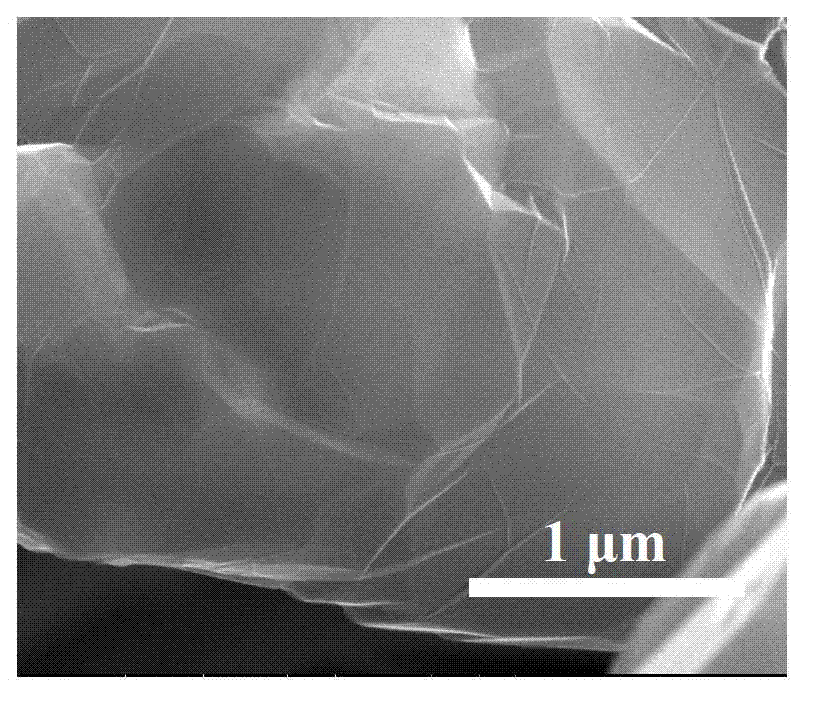

[0043] Example 1: Put 5g of nickel powder into a quartz tube, and pass through argon: 100 sccm, hydrogen 200 sccm for 15 min. Raise the tube furnace to 900°C, the atmosphere environment is: hydrogen: 200 sccm, argon: 100 sccm, methane: 30 sccm; keep the air pressure at 500 torr for 30 minutes. After the growth is completed, pass argon gas at 200 sccm until the quartz tube cools down to obtain multilayer graphene-coated nickel powder, whose morphology can be found in Figure 2a and Figure 2b and image 3 .

Embodiment 2

[0044] Embodiment 2: 5g of nickel nickel chloride powder and 500mg of expanded graphite are ball milled and mixed, put into a quartz tube, and pass through argon: 100sccm, hydrogen 200sccm for 15min. Raise the tube furnace to 900°C, the atmosphere environment is: hydrogen: 200 sccm, argon: 100 sccm, methane: 30 sccm; keep the air pressure at 500 torr for 30 minutes. After the growth is completed, pass argon gas at 200 sccm until the quartz tube cools down to obtain nickel powder covered by multi-layer graphene. The characterization results can be found in Figure 4 .

Embodiment 3

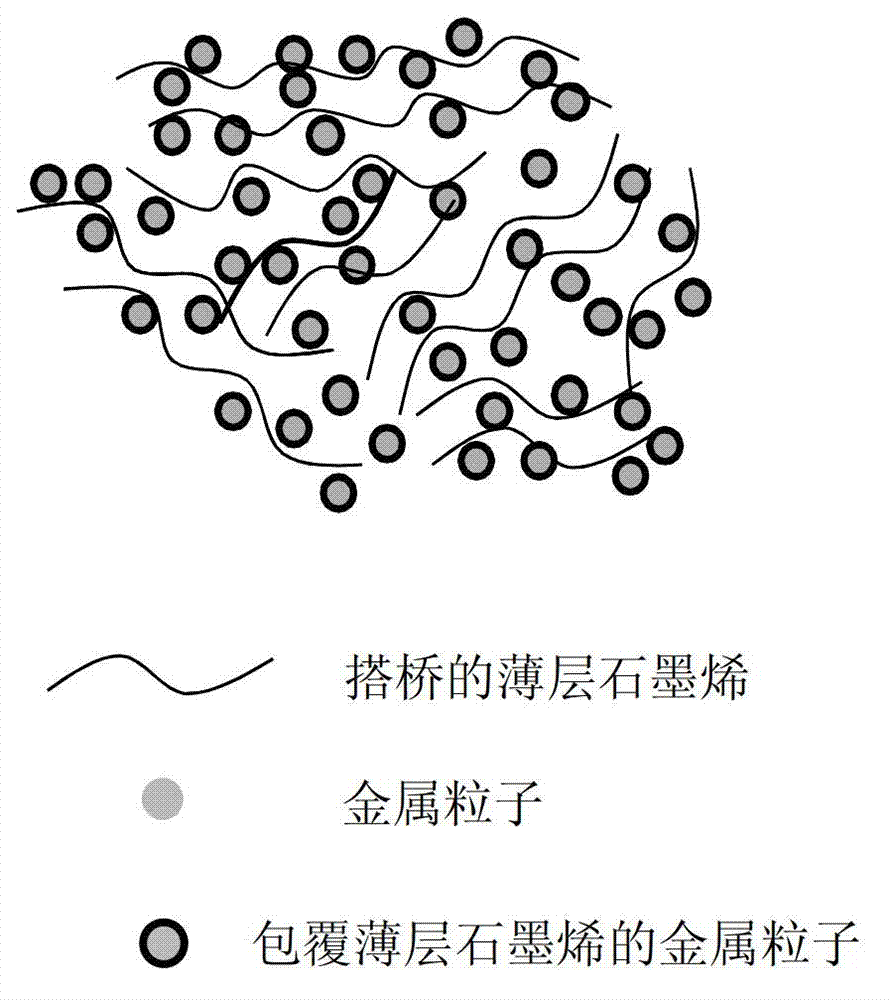

[0045] Example 3: Stir and mix the saturated nickel chloride solution and the graphene oxide solution, freeze-dry, put into a tube furnace, keep at 600°C for 10 minutes, and the atmosphere is: hydrogen: 300 sccm, argon: 100 sccm. Then raise the tube furnace to 1000°C and keep it at 1000°C for 10 minutes. At this time, the atmosphere is: methane: 30sccm, hydrogen: 200sccm, argon: 200sccm, keep it for 10 minutes, take out the quartz tube and cool it to room temperature to obtain graphene Nickel powder lapped and clad.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com