Fluorin-silicon modified core-shell structure polyurethane-acrylate emulsion preparation method

A technology modified by acrylate and fluorosilicone, which is applied in the direction of polyurea/polyurethane coatings and coatings, can solve the problems of high surface tension of emulsions, restrictions on wide application, poor resistance to organic solvents and water resistance, etc., to improve water resistance, The effect of expanding the field of use and reducing the amount of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

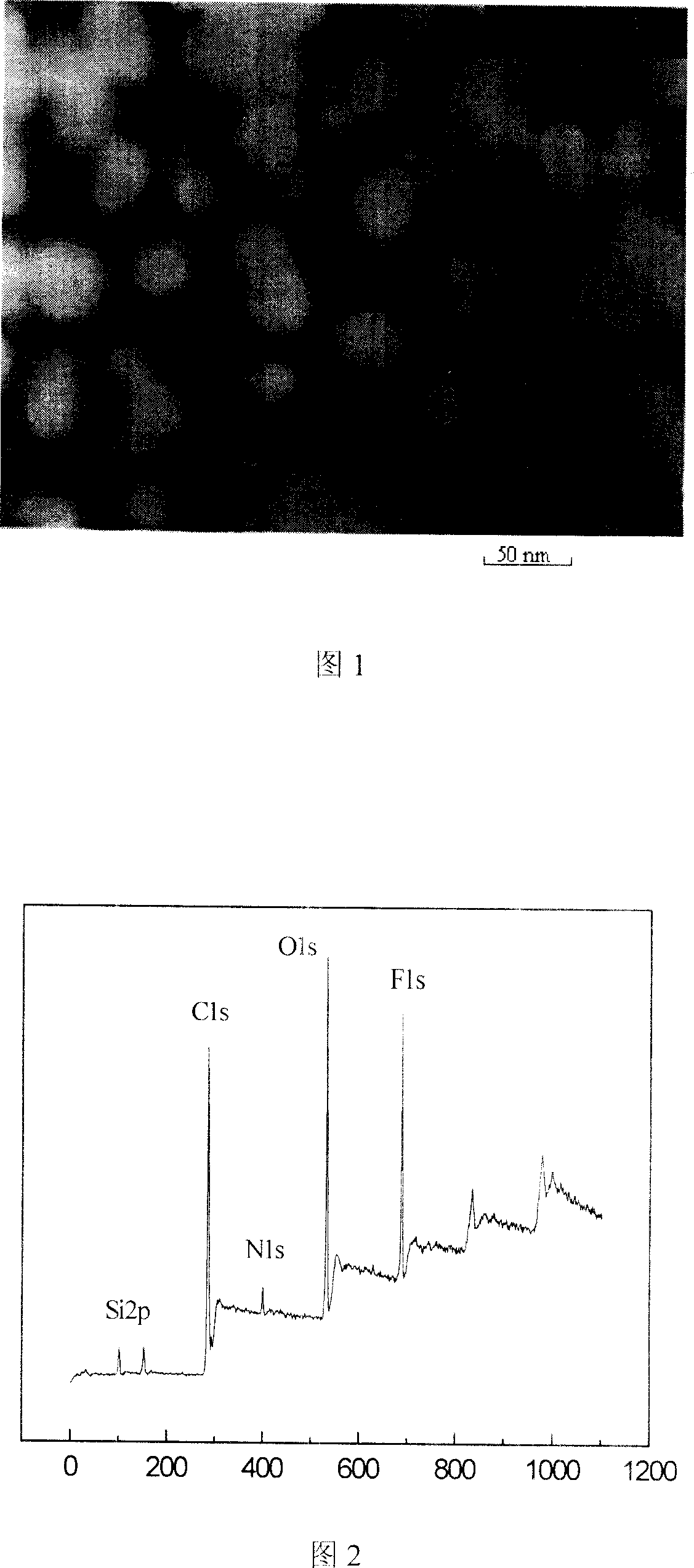

Image

Examples

Embodiment 1

[0019] 1. First prepare the silicone-modified water-based polyurethane dispersion:

[0020] Add 30.1 grams of PTMG and 6.5 grams of PDMS into a 500ml three-necked flask, dehydrate at 100°C for 1.5 hours, add 47.9 grams of IPDI, stir and react at 100°C for 2 hours, add 6.5 grams of hydrophilic chain extenders DA, 9.4 gram of BDO, 22 gram of methyl ethyl ketone and 0.073 gram of dibutyltin dilaurate were stirred and reacted at 90°C for 2 hours, then cooled to 10°C, transferred to a high-speed shear disperser, and added under the condition of 800 rpm 5 grams of triethylamine, reacted for 1 minute, added 272 grams of water and 3.2 grams of IPD, stirred for 10 minutes, then transferred to a rotary evaporator, and removed methyl ethyl ketone at 60 ° C and -0.1 MPa vacuum conditions to obtain silicone modified Waterborne polyurethane dispersion.

[0021] 2. Use silicone-modified water-based polyurethane dispersion as the seed for emulsion polymerization:

[0022] Weigh 100 grams of...

Embodiment 2

[0028] Add 32.8 grams of PJ and 3 grams of PDMS into a 500ml three-neck flask, dehydrate at 110°C for 1 hour, add 75.5 grams of MDI, stir and react at 80°C for 4 hours, add 12.3 grams of hydrophilic chain extender DA, 15.9 grams HDO, 55 grams of acetone and 0.018 grams of dibutyltin dilaurate were stirred and reacted at 60 ° C for 4 hours, cooled to 0 ° C, transferred to a high-speed shear disperser, and 9.5 grams of triethylamine was added under the condition of 2000 rpm , reacted for 2 minutes, added 418 grams of water and 13.5 grams of HD, stirred for 1 minute, then transferred to a rotary evaporator, 50 ° C, 0.09MPa vacuum conditions to remove acetone, that is, a silicone-modified water-based polyurethane dispersion.

[0029] Weigh 100 grams of the above silicone-modified polyurethane dispersion, add it to a 250ml three-necked flask, add 3 grams of OP-10, stir and heat to 75°C, add 10 grams of MMA and 20 grams of HFBMA dropwise at a rate of 15 drops / minute, At the same tim...

Embodiment 3

[0032] Add 69.2 grams of PCD and PPG mixture and 28.5 grams of PDMS into a 500ml three-neck flask, dehydrate at 120°C for 0.5 hours, add 50 grams of TDI, react at 90°C for 3 hours, add 6.7 grams of hydrophilic chain extender DA, 7.2 grams of CX, 58.5 grams of acetone and 0.069 grams of dibutyltin dilaurate, stirred and reacted at 65 ° C for 3 hours, cooled to 5 ° C, transferred to a high-speed shear disperser, and added triethyl tin at 4000 rpm 6.5 grams of amine, reacted for 3 minutes, added 342 grams of water and 25 grams of a mixture of IPD and HD, stirred for 5 minutes, then transferred it to a precipitation tank, and removed acetone at 40 ° C and 0.08 MPa vacuum to obtain organosilicon Modified waterborne polyurethane dispersion.

[0033] Weigh 100 grams of the above silicone-modified polyurethane dispersion, add it to a 250ml three-necked flask, add a mixture of 1 gram of OP-10 and SDS, stir and heat to 80°C, and dropwise add 15 grams of BA and 15 1 gram of LFHMA, while...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com