Graphene-polysiloxane composite material and preparation method thereof as well as micro-fluidic chip and application thereof

A polyorganosiloxane, microfluidic chip technology, applied in chemical instruments and methods, fluid heaters, laboratory containers, etc., can solve the problems of poor stability, difficult to widely use, and difficult in the visible light region, etc. To achieve the effect of uniform and stable performance, easy operation and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

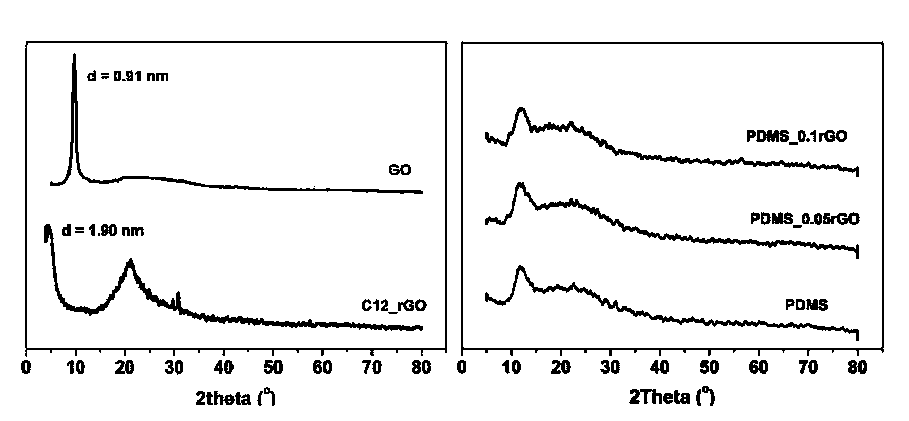

[0032] A kind of graphene-polyorganosiloxane composite material of the present invention, this graphene-polyorganosiloxane composite material is mainly made up of polyorganosiloxane matrix and graphene (see figure 1 with figure 2 ),Depend on figure 1 with figure 2It can be seen that graphene is uniformly dispersed in the polyorganosiloxane matrix; the mass ratio of graphene to polyorganosiloxane matrix is 0.001:1; graphene is modified by an alkyl chain (dodecyl group selected in this embodiment) The graphene, polyorganosiloxane matrix is polydimethylsiloxane.

[0033] The preparation method of the graphene-polyorganosiloxane composite material of the present embodiment may further comprise the steps:

[0034] (1) Preparation of graphene oxide: Put a three-necked round-bottomed flask in an ice-water bath, add a mixture of 1 g of high-purity graphite and 6 g of potassium permanganate mixed in advance, and slowly add a mixed acid solution (containing 120 mL of concentrat...

Embodiment 2

[0041] A microfluidic chip prepared from the graphene-polyorganosiloxane composite material in Example 1, the specific preparation process of the microfluidic chip includes:

[0042] (1) Prepare the precursor mixed system according to the steps (1) to (3) in Example 1;

[0043] (2) Pour the above precursor mixed system into a container with a microfluidic chip template, let it stand for 10 minutes, and then heat and cure at 65°C for 3 hours to obtain a cured microfluidic chip;

[0044] (3) The above cured microfluidic chip solidified body is removed from the microfluidic chip template to obtain the microfluidic chip of this embodiment.

[0045] Such as image 3 As shown, the microfluidic chip of this embodiment is used as an optical heating platform. When the optical heating is applied, the microfluidic chip is irradiated by a heating light source to increase the temperature of the fluid in the pipeline of the microfluidic chip. The wavelength of the light source is 650nm, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com