Combined collecting agent for flotation of scheelite and gangue minerals and flotation method thereof

A technology combining collectors and gangue minerals, applied in flotation, solid separation and other directions, can solve the problem of difficulty in separating target minerals and calcium-containing gangue minerals, and achieve selectivity and collection enhancement, flotation conditions Requires loose, highly selective effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

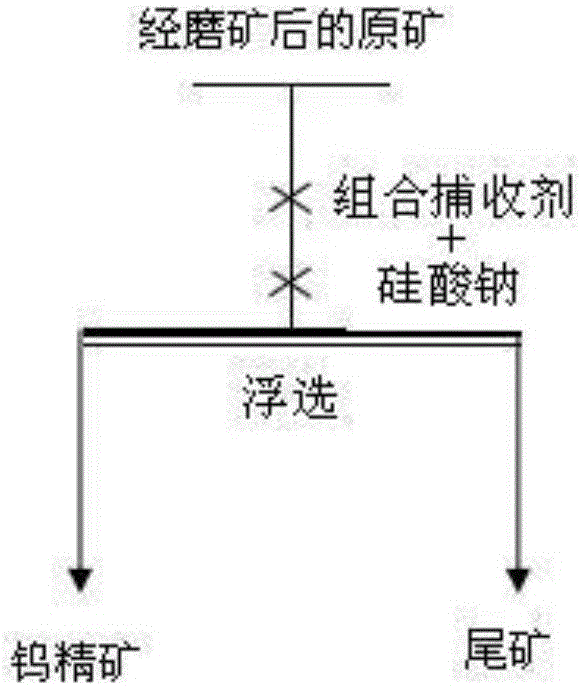

[0036] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings of the present invention. Obviously, the described embodiments are only part of the embodiments of the present invention, not all of them.

[0037] A combined collector for flotation scheelite and gangue minerals and a flotation method thereof, the specific composition of which is octanoylhydroxamic acid (C 8 h 17 NO 2 ) and sodium oleate (C 18 h 33 o 2 Na) A mixture formed by combining in a mass ratio of 1:1 to 1:6.

[0038] The following formula is the molecular structural formula of octanoylhydroxamic acid:

[0039]

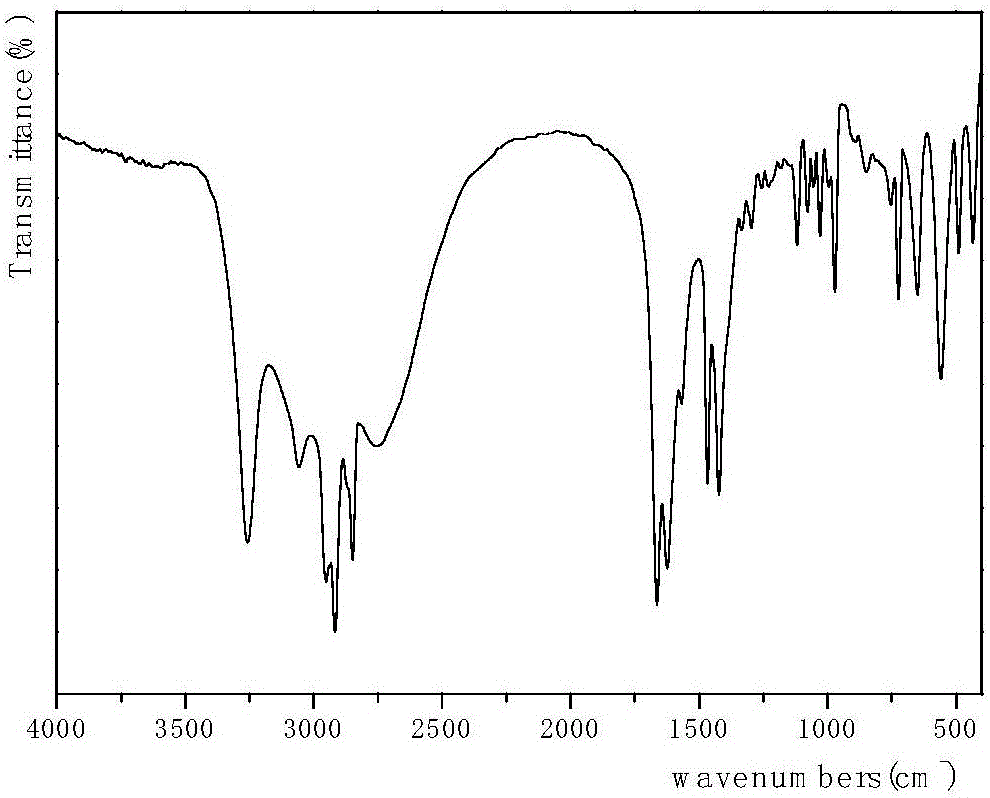

[0040] The infrared spectrum of caprylylhydroxamic acid is detailed in figure 2 .

[0041] The following formula is the molecular structural formula of sodium oleate:

[0042]

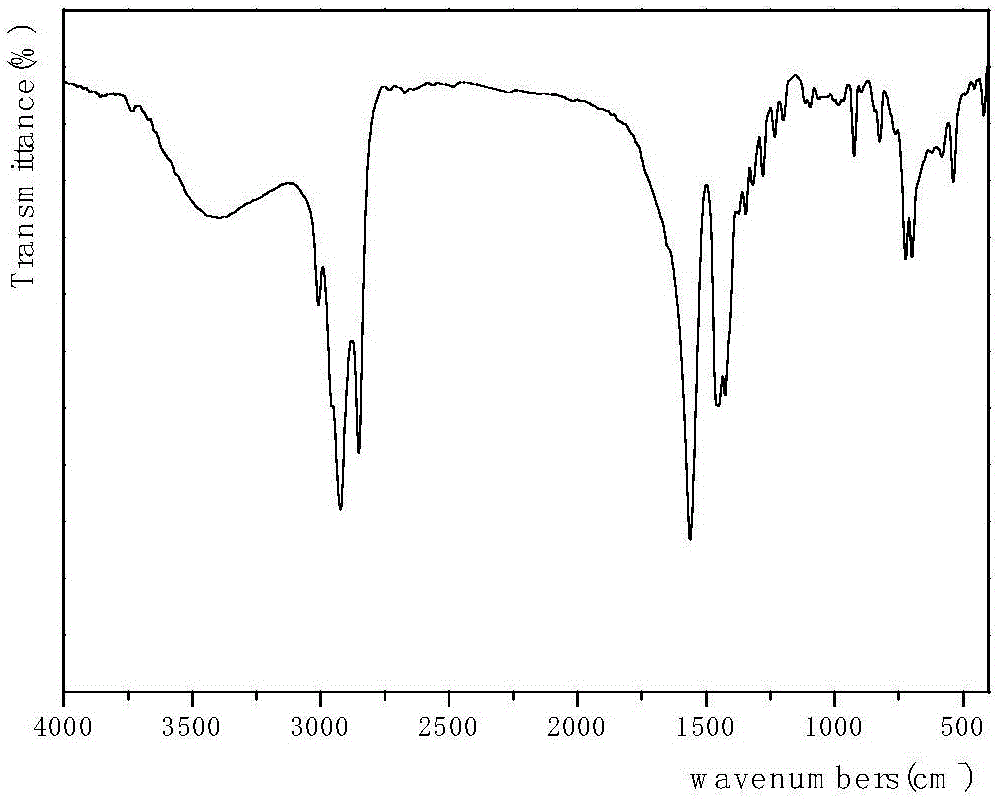

[0043] The infrared spectrum of sodium oleate is detailed in image 3 .

[0044] Further, the mass ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com