Fat-coated fodder acidifying agent

A feed acidifier and acidifier technology, applied in the field of feed additives, can solve the problems of expensive coating materials, low content of active substances, and high manufacturing costs, and achieve the effects of saving coating materials, simple process, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The coating material is formulated with palm stearin 60% + higher fatty acid polyol polyester 20% + glyceryl monostearate 20%.

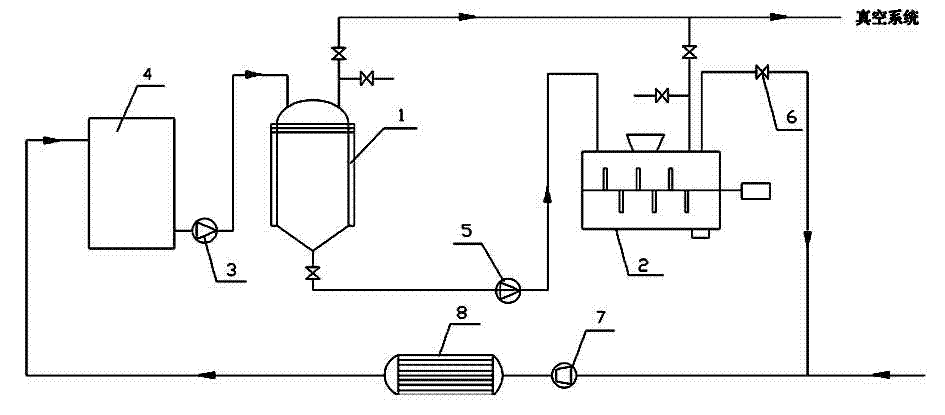

[0026] like figure 1 As shown, add 100Kg of the coating material (packaging material) prepared according to the above ratio into the dissolution kettle 1 (with agitator or ultrasonic generator, pressure P≥2MPa), and vacuum through the vacuum system until the vacuum indication number is 0.09 MPa, open the hydrocarbon pump 3 to pass the liquefied petroleum gas solution 800L in the storage tank 4 into the dissolution kettle 1 (normal butane, high-purity isobutane, propane, dimethyl ether, 1,1,1,2 - liquid solvents such as tetrafluoroethane or sulfur hexafluoride, the liquid solvent can be compressed in advance, cooled and stored in the storage tank 4), heated and stirred to dissolve the packaging material.

[0027] Add 200kg of solid citric acid with a particle size of 0.01~0.5mm into the vacuum rake dryer 2, and vacuum through the vacuum system...

Embodiment 2

[0029] The coating material is formulated with hydrogenated vegetable oil 70% + glyceryl monostearate 20% + polymerized glycerol fatty acid ester 10%.

[0030] like figure 1 As shown, add 200Kg of packaging material to the dissolution tank 1 (with agitator or ultrasonic generator, pressure P≥2MPa), vacuumize through the vacuum system until the vacuum indicator is 0.09MPa, and turn on the hydrocarbon pump 3 to move the storage tank 4 1000L of the liquefied petroleum gas solution in the solution is passed into the dissolution kettle 1 (n-butane, high-purity isobutane, propane, dimethyl ether, 1,1,1,2-tetrafluoroethane or sulfur hexafluoride can also be used and other liquid solvents, the liquid solvents can be compressed in advance, cooled and stored in the storage tank 4), stirred to dissolve the packaging material, and the dissolution temperature is less than 50°C.

[0031] Add 200 kg of solid potassium diformate with a particle size of 0.01 to 0.5 mm into the vacuum rake dry...

Embodiment 3

[0033] The coating material is formulated with hydrogenated vegetable oil 50% + glyceryl adipate stearate 30% + glyceryl monostearate 10% + polymerized glycerin fatty acid ester + 10%.

[0034] like figure 1 As shown, add 90Kg of packaging materials into the dissolution tank 1 (with agitator or ultrasonic generator, pressure P≥2MPa), vacuumize through the vacuum system until the vacuum indicator is 0.09MPa, and turn on the hydrocarbon pump 3 to move the storage tank 4 800L of n-butane solution in the solution is passed into the dissolution kettle 1 (liquefied petroleum gas, high-purity isobutane, propane, dimethyl ether, 1,1,1,2-tetrafluoroethane or sulfur hexafluoride can also be used and other liquid solvents, the liquid solvents can be compressed in advance, cooled and stored in the storage tank 4), stirred to dissolve the packaging material.

[0035] Add 210kg of sodium butyrate (particle size: 0.15mm) to the vacuum rake dryer 2, vacuum through the vacuum system until the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com