Tamping coke oven smoke treatment system and smoke treatment method thereof

A technology for tamping coke ovens and dust removal systems. It is applied in coke ovens, furnaces to prevent/remove fouling, and the petroleum industry. Safe and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

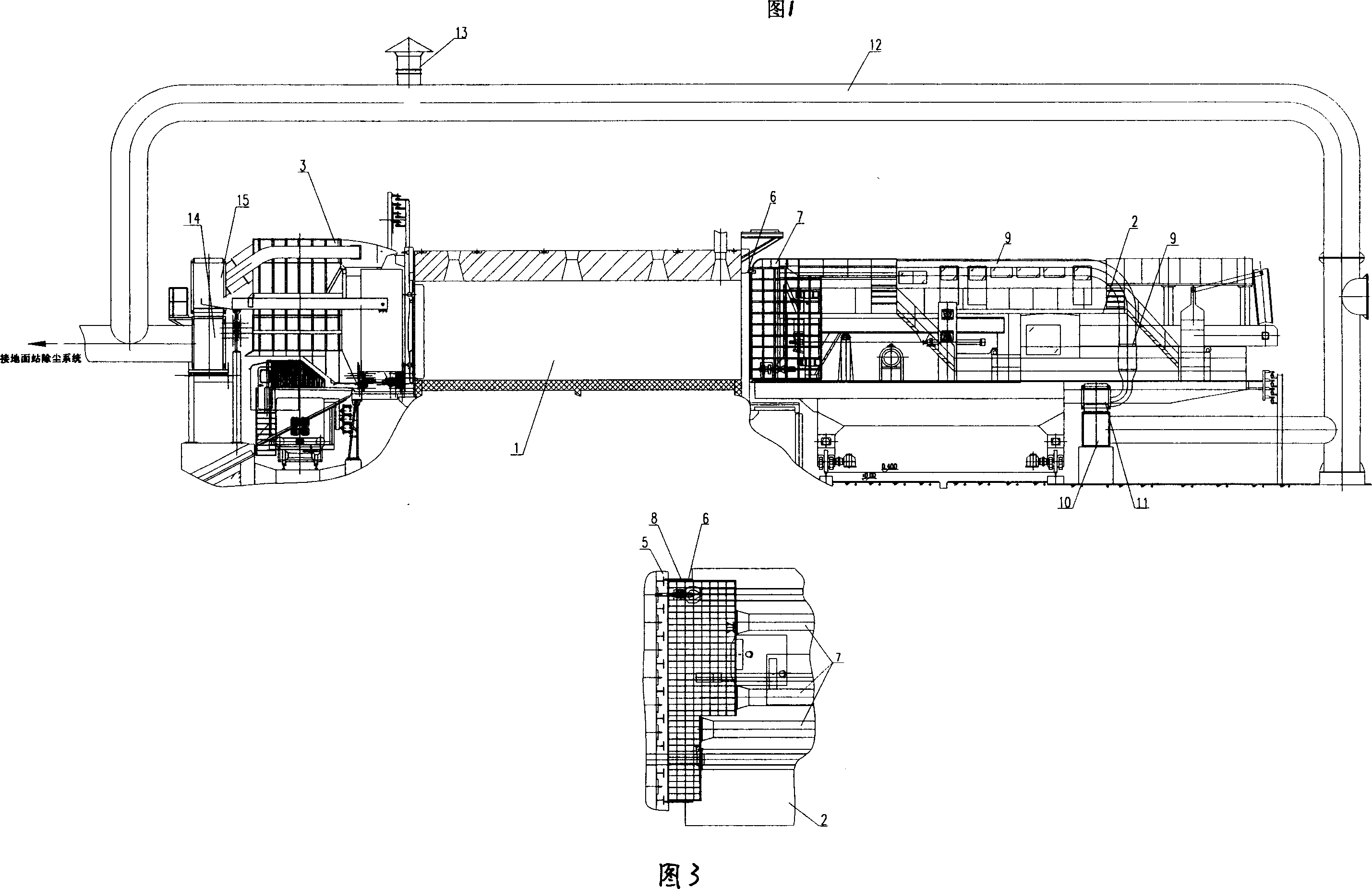

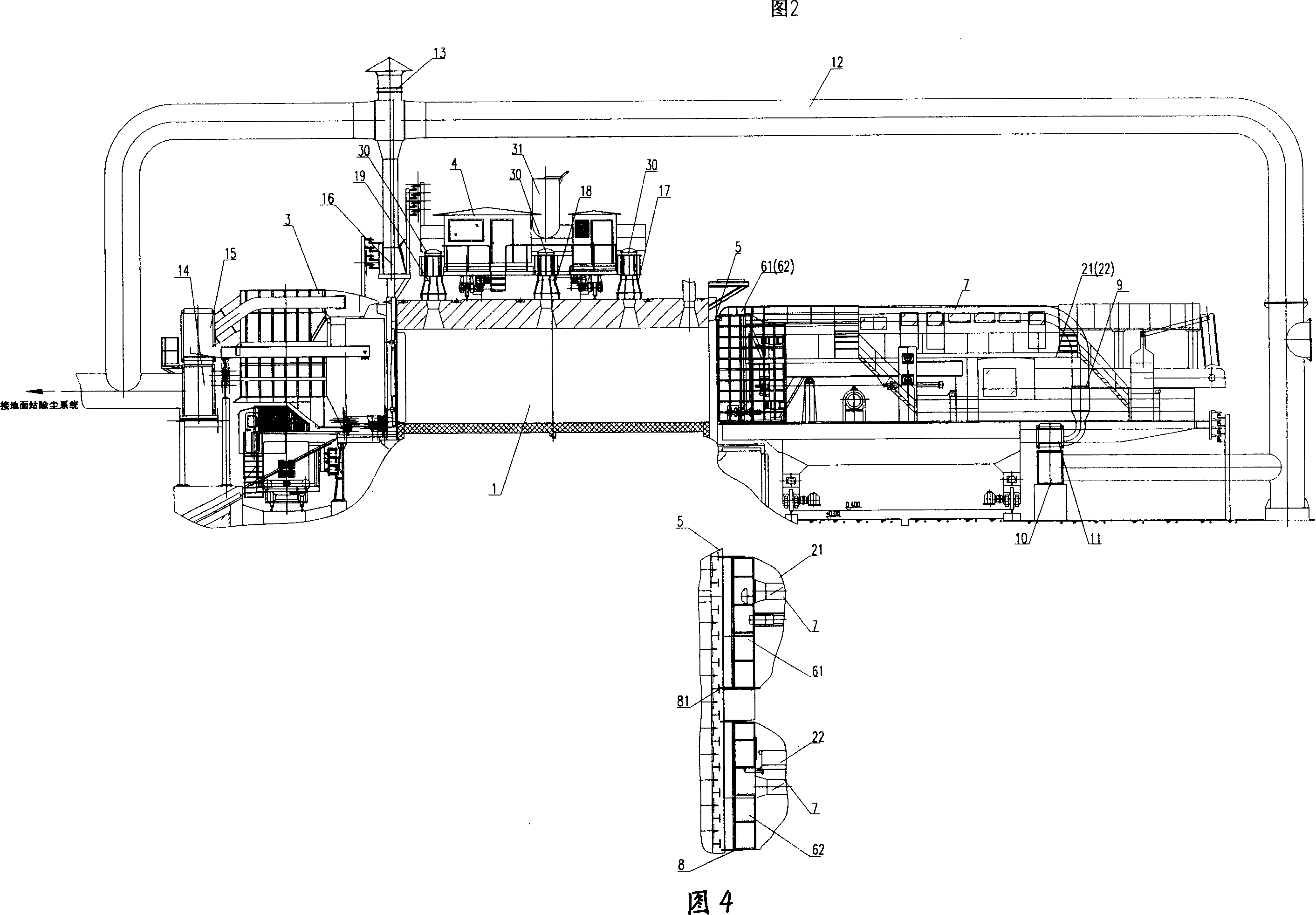

[0025] As shown in Fig. 1, the first embodiment of the present invention is the smoke control equipment when coal is charged at a relatively low speed. Wherein, a machine-side smoke and dust collection device is arranged on the machine side of the tamping coke oven (1), and the gas collecting pipes of the machine-side smoke and dust collection device are collected and transported to the machine-side ground smoke through a pipeline stepless docking device (11). Pipe (10) is connected, and the smoke and dust collection device on the side of the machine adopts a large air volume during operation to form a continuous, unequal negative pressure dust collection area at the furnace door, so as to capture the smoke and dust that escapes from the furnace door when the coal is loaded on the side of the machine. ; The coke side of the tamping coke oven (1) is provided with a dust removal and coke arresting vehicle (3), which is connected to the coke side flue gas delivery main pipe throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com