Heat recovery coke oven fixed cover type machine side dust-removing technique

A fixed hood and heat recovery technology, which is applied to coke ovens, smoke and dust removal, coke oven parts, etc., can solve the problems that restrict the promotion and use of heat recovery coke ovens, the long duration of overflowing smoke and dust, and the complexity of flue gas components, etc., to achieve Reduce the one-time investment, reduce the discharge of harmful substances, and improve the effect of operating conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

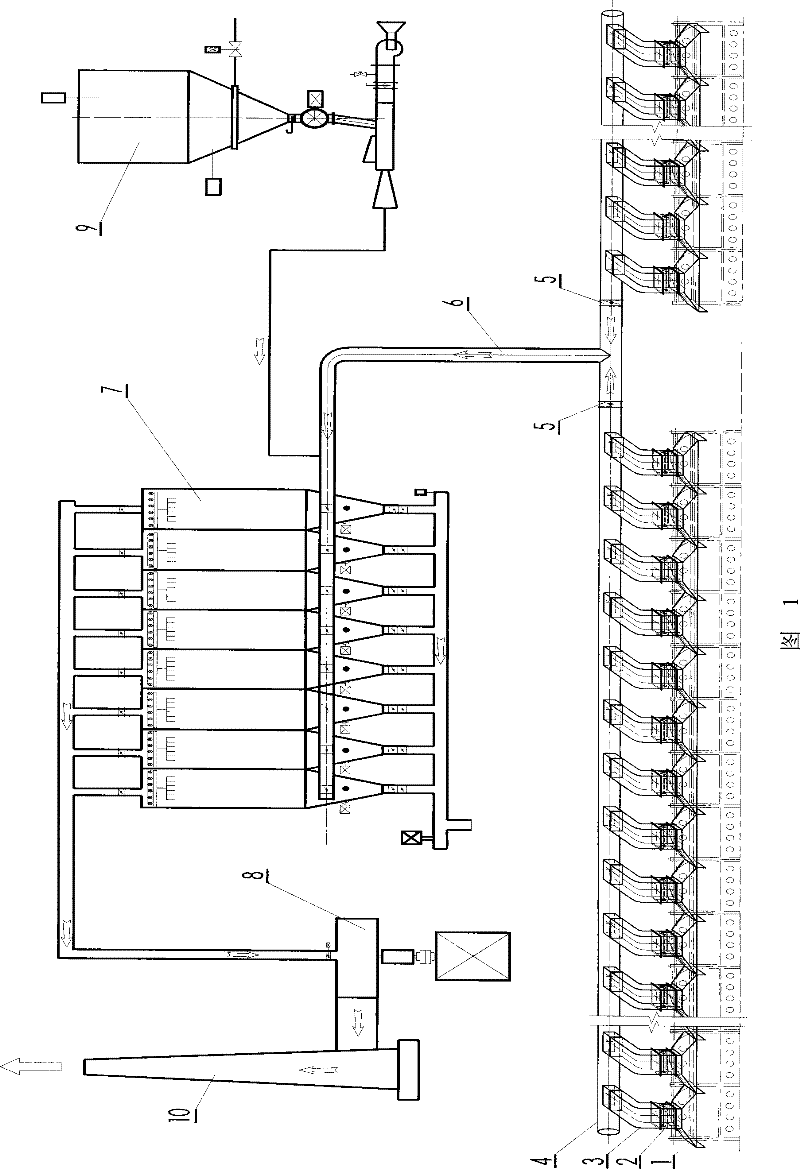

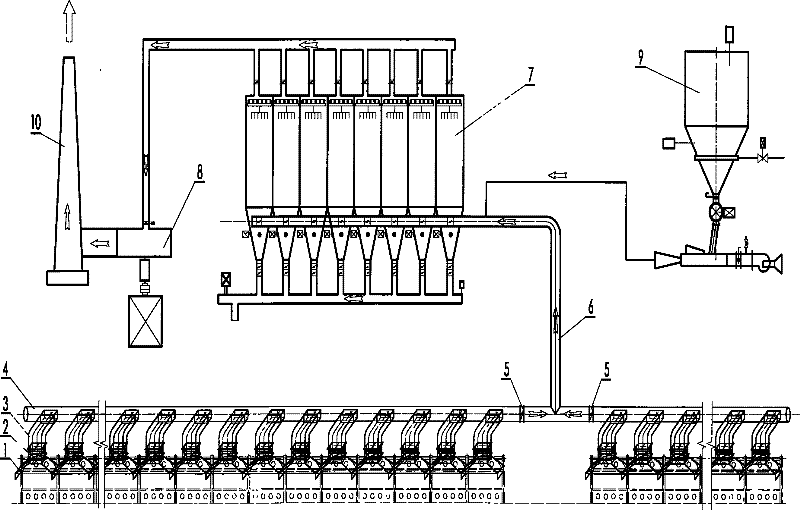

[0018] Describe the concrete content of the present invention in detail below in conjunction with accompanying drawing:

[0019] See figure 1 , heat recovery coke oven fixed cover machine side dust removal process, including fixed dust collection cover 1 set on the upper part of the furnace door, normally closed conduction valve 2, conduction pipe 3, furnace top dust collection dry pipe 4, normally closed Furnace group switching valve 5, connecting pipe 6, bag filter 7, speed-adjustable dust removal ventilation unit 8, pre-spraying device 9, chimney 10. A plurality of fixed dust collection hoods 1 are closely arranged, and each fixed dust collection hood 1 covers the upper part of the coke oven door of each hole, and smoke baffles are arranged on both sides of the fixed dust collection hood 1 . The fixed dust collection cover 1 is connected with the normally closed conduction valve 2 and the conduction pipe 3 in sequence, and the upper part of the conduction pipe 3 communicat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com