Delayed coking production method utilizing ethylene cracking tar as raw material

A technology of ethylene cracking and delayed coking, which is applied in cracking, non-catalytic thermal cracking, petroleum industry, etc., to achieve the effect of increasing coke yield and comprehensive utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Mixed raw material plan for blending 5% ethylene pyrolysis tar: the delayed coking mixed raw material is composed of Daqing ethylene pyrolysis tar, Daqing vacuum residue and Daqing catalytic oil slurry, and the weight ratio is 1:17:2, that is, ethylene pyrolysis tar accounts for 5%. , Vacuum residual oil accounts for 85%, and catalytic oil slurry accounts for 10%. During the experiment, 15ppm (accounting for feed) YJ-01 defoamer was injected into the top of the coke tower.

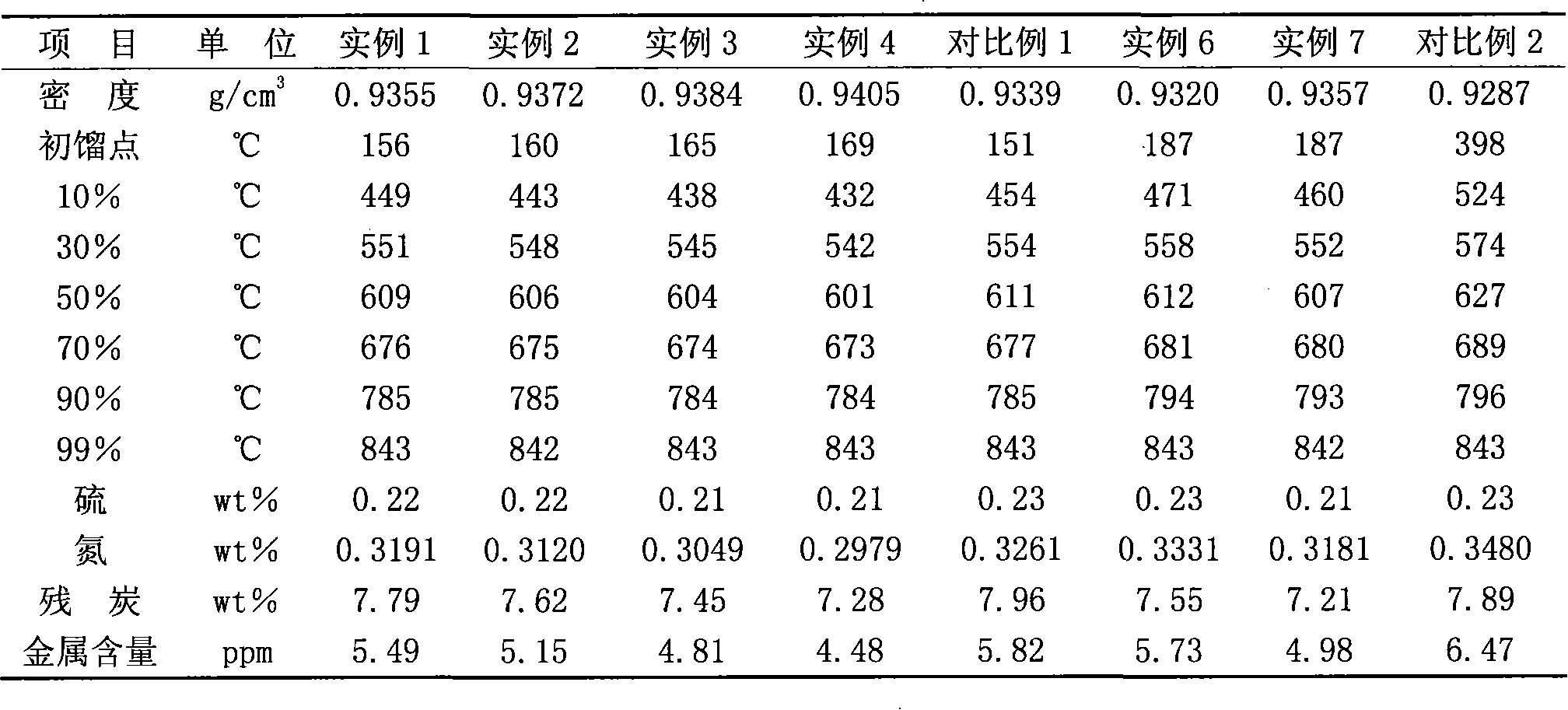

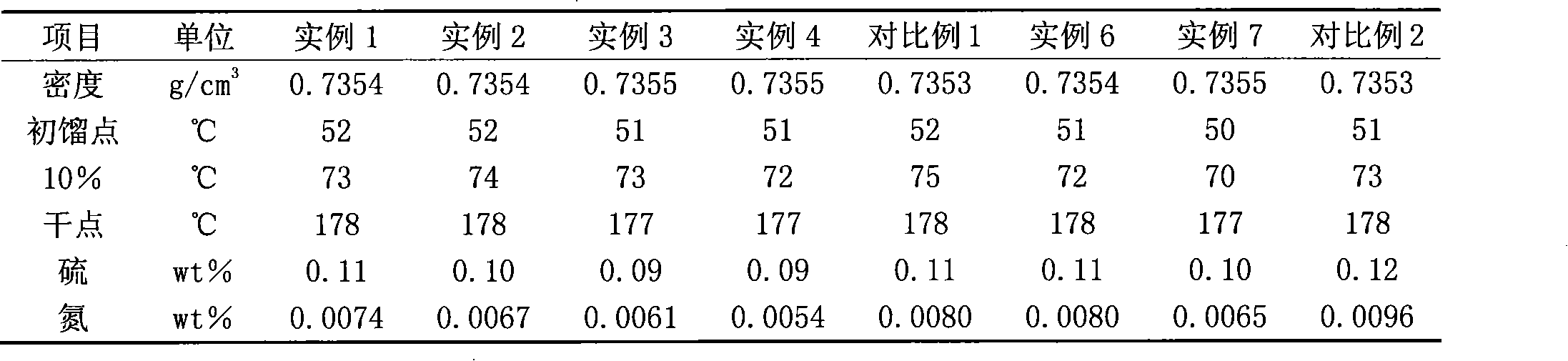

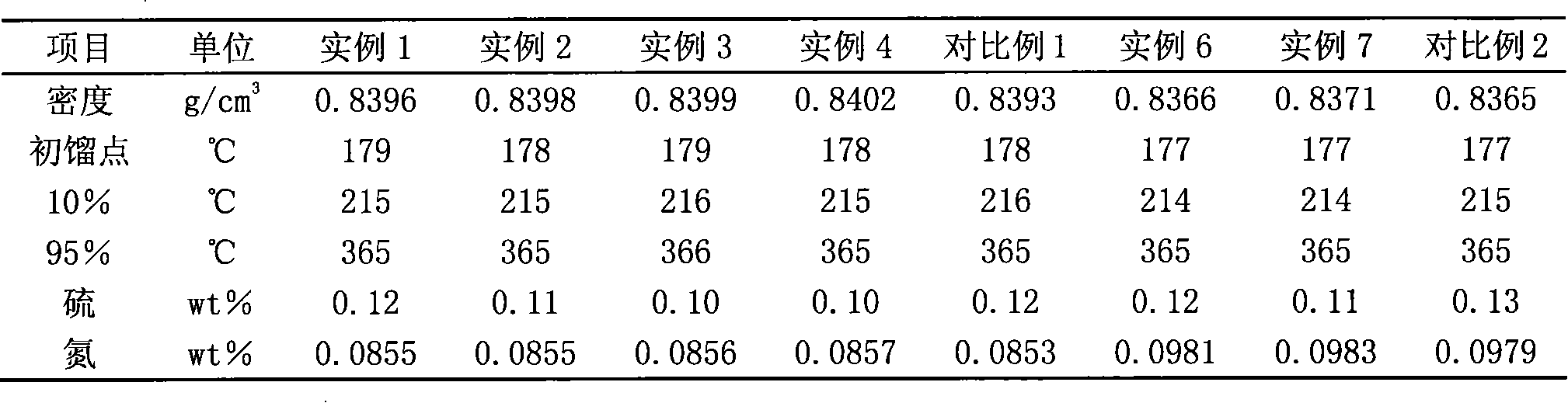

[0017] Through the analysis of the mixed raw materials of ethylene cracking tar, vacuum residue and catalytic oil slurry, the evaluation of mixed raw materials with different blending ratios was carried out in the delayed coking experimental device. The feed rate of the delayed coking device was 3kg / h, and the reaction pressure 0.16MPa (table), reaction temperature 500°C, circulation ratio 0.35, raw material properties of different raw material mixing schemes are shown in Table 1, main product gasol...

Embodiment 2

[0019] Mixed raw material plan for blending 10% ethylene cracking tar: the delayed coking mixed raw material is composed of Daqing ethylene cracking tar, Daqing vacuum residue and Daqing catalytic oil slurry, and the weight ratio is 1:8:1, that is, ethylene cracking tar accounts for 10%. , Vacuum residual oil accounts for 80%, and catalytic oil slurry accounts for 10%. During the experiment, 15ppm (accounting for feed) YJ-01 defoamer was injected into the top of the coke tower

[0020] Through the analysis of the mixed raw materials of ethylene cracking tar, vacuum residue and catalytic oil slurry, the evaluation of mixed raw materials with different blending ratios was carried out in the delayed coking experimental device. The feed rate of the delayed coking device was 3kg / h, and the reaction pressure 0.16MPa (table), reaction temperature 500°C, circulation ratio 0.35, raw material properties of different raw material mixing schemes are shown in Table 1, main product gasoline...

Embodiment 3

[0022] Mixed raw material plan for blending 15% ethylene cracking tar: the delayed coking mixed raw material is composed of Daqing ethylene cracking tar, Daqing vacuum residue and Daqing catalytic oil slurry, with a weight ratio of 1:5:0.67, that is, ethylene cracking tar accounts for 15% , Vacuum residual oil accounted for 75%, catalytic oil slurry accounted for 10%. During the experiment, 15ppm (accounting for feed) YJ-01 defoamer was injected into the top of the coke tower

[0023] Through the analysis of the mixed raw materials of ethylene cracking tar, vacuum residue and catalytic oil slurry, the evaluation of mixed raw materials with different blending ratios was carried out in the delayed coking experimental device. The feed rate of the delayed coking device was 3kg / h, and the reaction pressure 0.16MPa (table), reaction temperature 500°C, circulation ratio 0.35, raw material properties of different raw material mixing schemes are shown in Table 1, main product gasoline ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com