Clasp assembly for a watch chain

a technology of clasp assembly and watch chain, which is applied in the direction of bracelets, wristwatch straps, apparel, etc., can solve the problems of inconvenient use and assembly of conventional watch chains, complicated structure of clasp assembly of metallic watch chains, and high cost, so as to improve the security of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

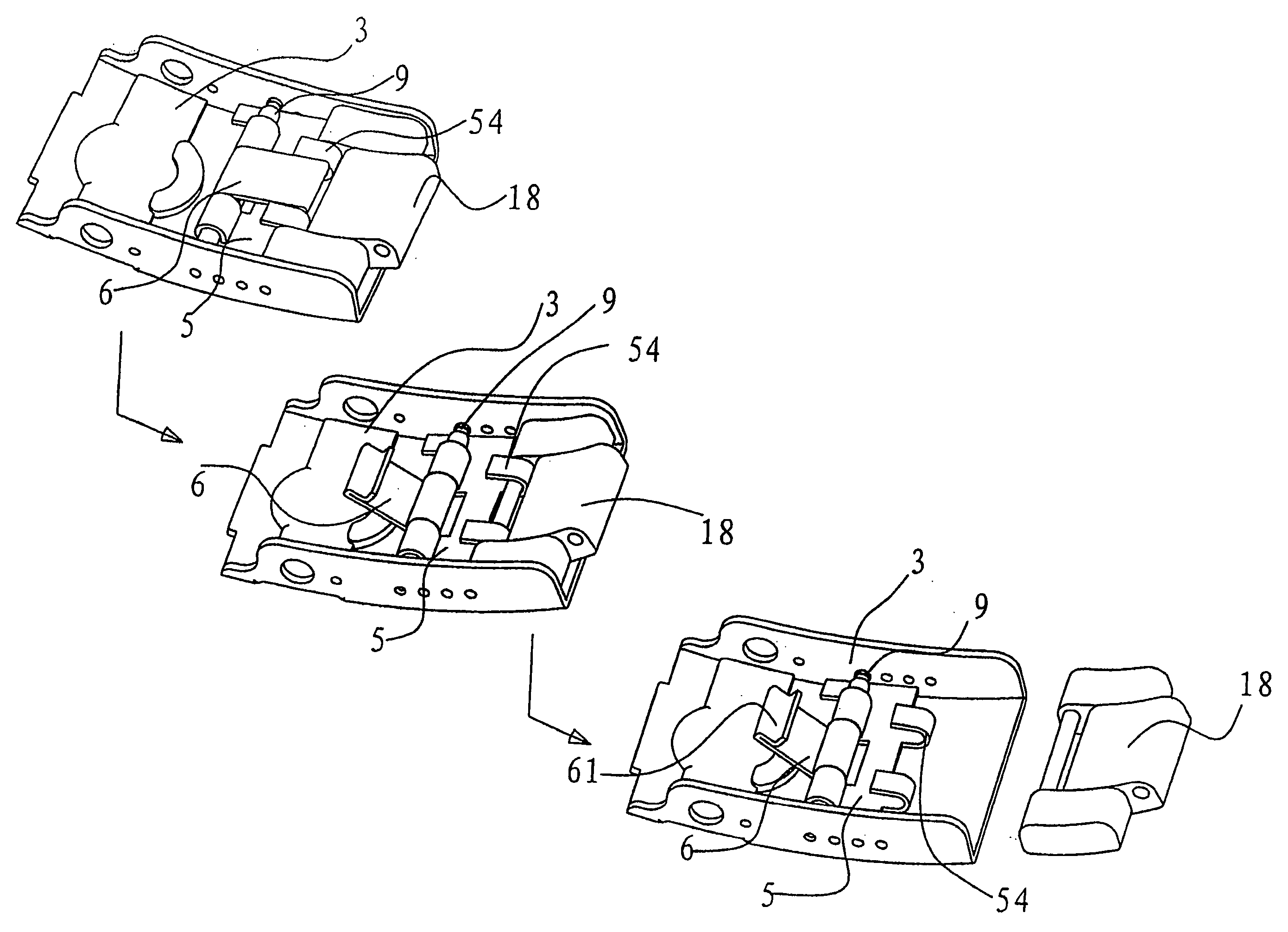

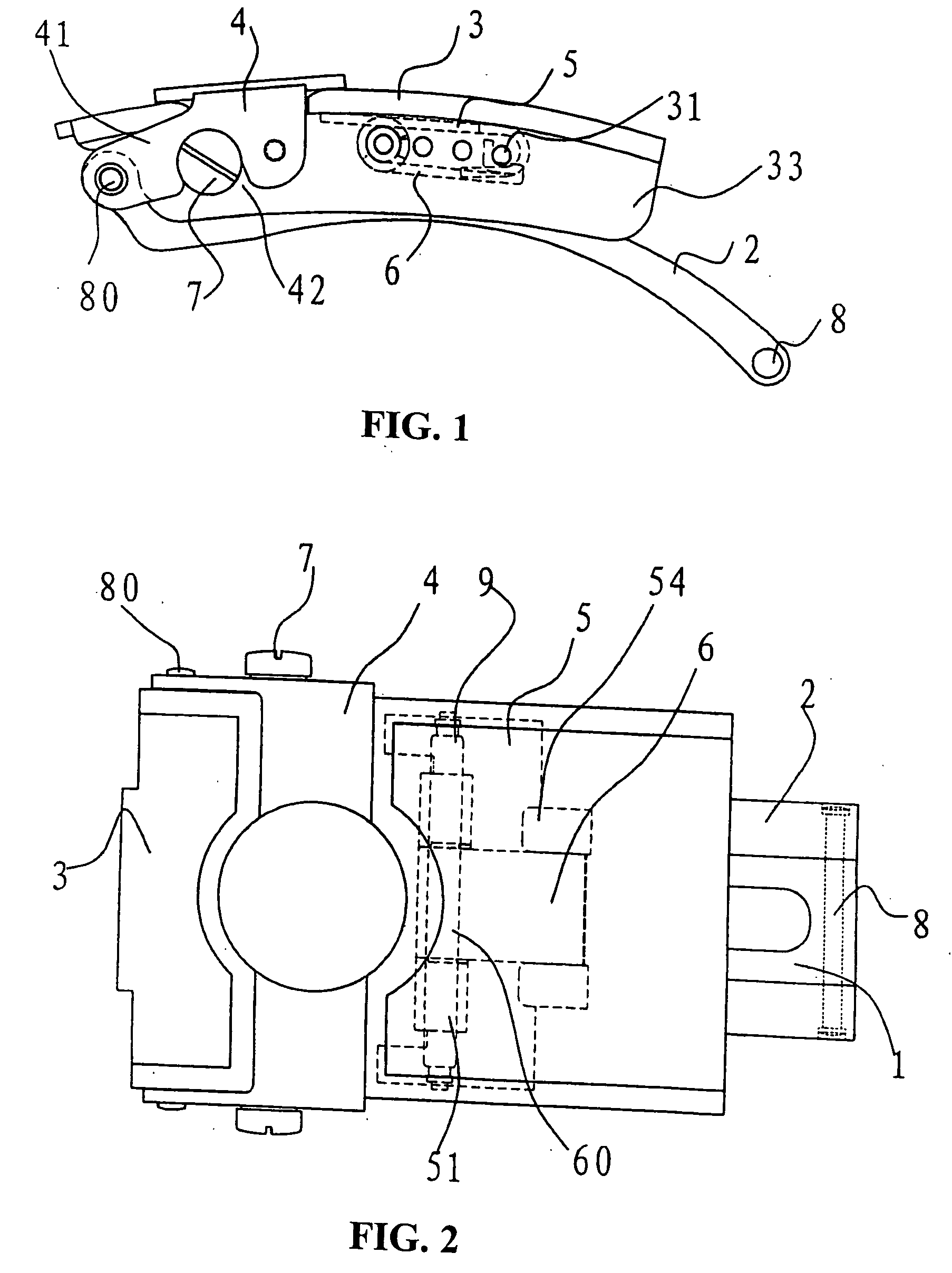

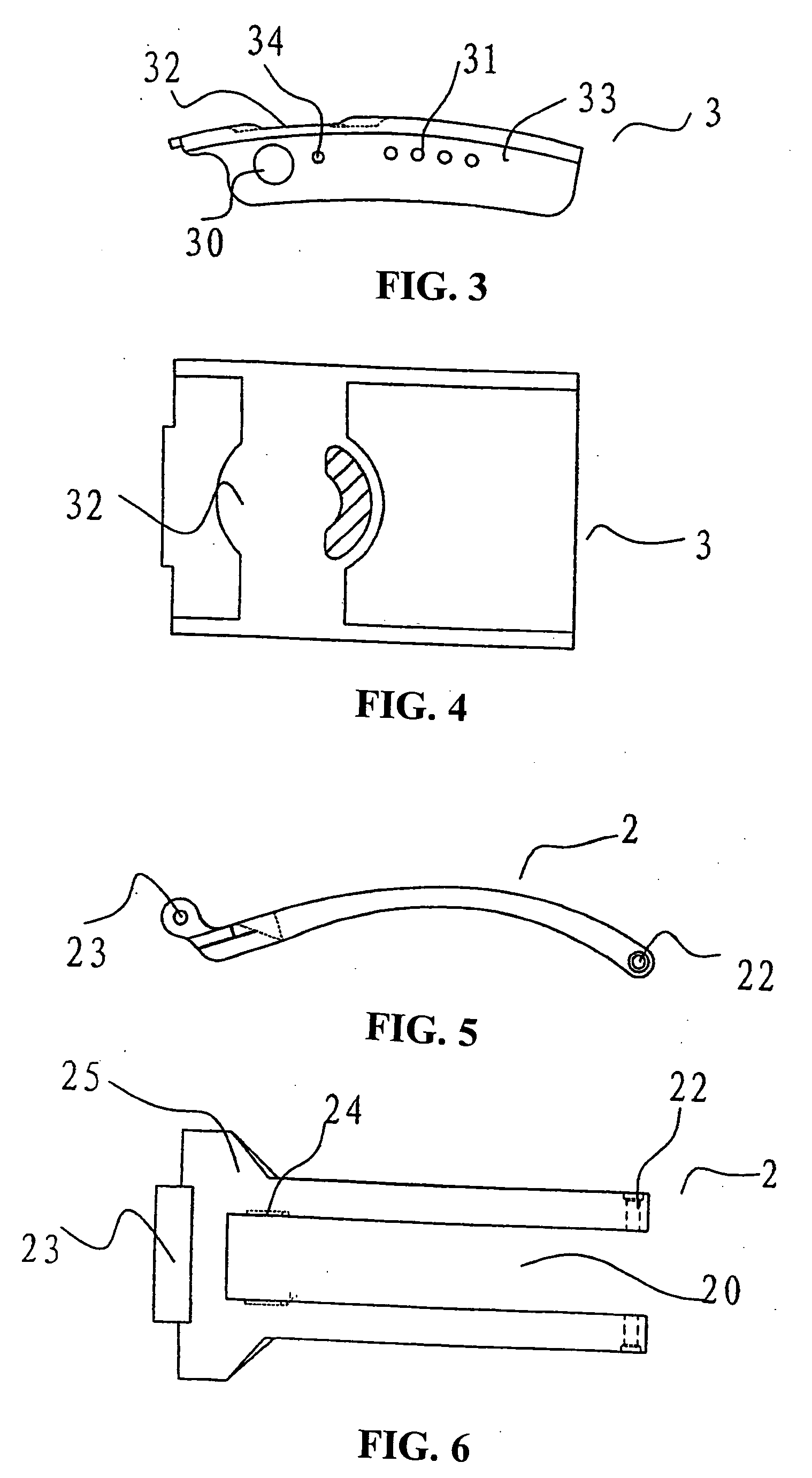

[0034] As shown in FIGS. 1 and 2, the clasp assembly of the present invention includes an inner bend plate 1, and an outer bend plate 2, a clasp cap 3, a security cover 4, a hook clasp 5, a locking clasp 6, a screw 7, a rivet 8 and an elastic shaft 9. The inner bend plate 1 is fitted into the outer bend plate 2, a convex clasp 15 and a concave clasp 16 therein engaging with each other so that the inner bend plate 1 and the outer bend plate 2 are combined into one bend plate, as shown in FIGS. 6 and 8. The clasp plate 3 is movably connected with the inner bend plate 1 through the screw 7, and can pivot slightly about the screw 7. The hook clasp 5 and the locking clasp 6 are mounted on the elastic shaft 9 in the inner side of the clasp cap 3, wherein the hook clasp 5 can pivot slightly about the shaft 9 and the locking clasp 6 can pivot about it in a large angle range. The watch chain 18 is connected with the hook clasp 5 and locked by the locking clasp 6. FIG. 14 shows the operation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com