Computing method of model parameters in icing wind tunnel experiment under supercooled large droplet condition

A technology of wind tunnel test and model parameters, which is applied in the field of aerospace, can solve the problems of poor freezing experiments of supercooled large water droplets and failure to reflect real icing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0115] The NACA0012 airfoil with a chord length of 0.5m is selected as the reference full-scale shape, and the test model size is taken as 0.3m.

[0116] The actual flight conditions are: chord length: L f =0.5m; flight speed: V f =95.0m / s; pressure: P f =91032Pa; water droplet diameter: d f =60μm; liquid water content: LWC f =0.22g / m 3 ; Freezing time: t f =6min; freezing temperature: T f =253K.

[0117] Adopt the technical scheme of the present invention, carry out calculation, the test parameter that can calculate model is: chord length: L m =0.3m; flight speed: V m =119.1m / s; droplet diameter: d m =38μm; liquid water content: LWC m =0.163g / m 3 ; Freezing time: t f =232.9s; freezing temperature: T f =255.2K.

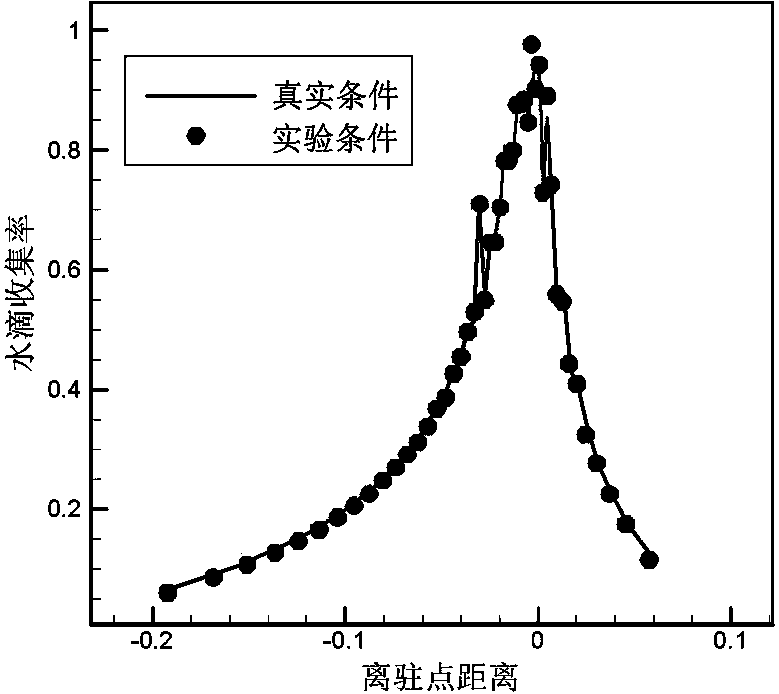

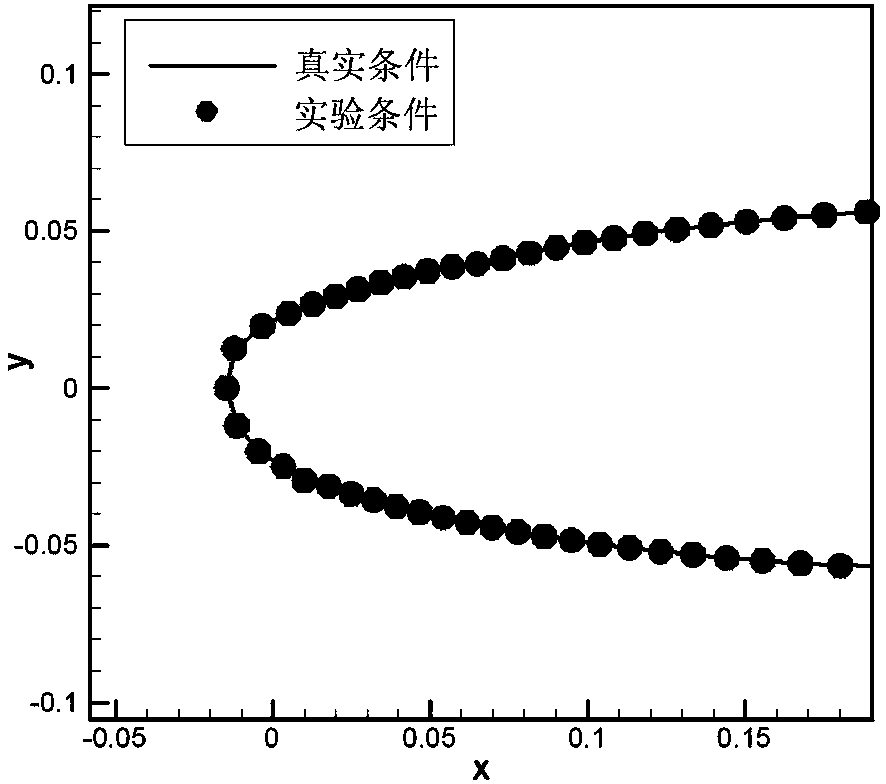

[0118] For the real flight condition of embodiment 1 and its corresponding test condition, figure 1 , 2 The comparison charts of the normalized results are given respectively. figure 1 is the comparison chart of normalized water droplet collection coe...

Embodiment 2

[0120] The NACA0012 airfoil with a chord length of 0.5m is selected as the reference full-scale shape, and the test model size is taken as 0.3m.

[0121] The actual flight conditions are:; chord length: L f =0.5m; flight speed: V f =90.0m / s; pressure: P f =89032Pa; water drop diameter: d f =80μm; liquid water content: LWC f =0.15g / m 3 ; Freezing time: t f =6min; freezing temperature: T f = 248K.

[0122] Corresponding to the real flight conditions, the calculated experimental parameters of the model are: chord length: L m =0.3m; flight speed: V m =113.6m / s; water droplet diameter: d m =50.2μm; liquid water content: LWC m =0.109g / m 3 ; Freezing time: t f =234.2s; freezing temperature: T f =251.2K.

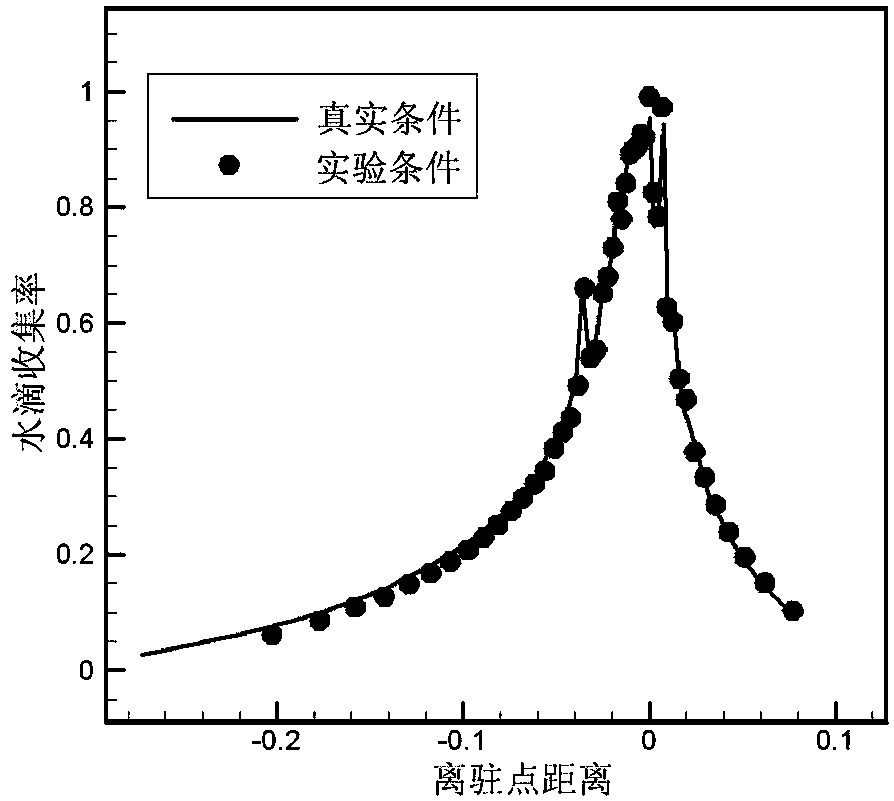

[0123] For the real flight condition of embodiment 2 and its corresponding test condition, image 3 , 4 The comparison charts of the normalized results are given respectively. image 3 is the comparison chart of normalized water droplet collection coefficient, Fig...

Embodiment 3

[0125] The NACA0012 airfoil with a chord length of 0.5m is selected as the reference full-scale shape, and the test model size is taken as 0.3m.

[0126] Real flight conditions: Chord length: L f =0.5m; flight speed: V f =89.0m / s; Pressure: P f =89032Pa; water drop diameter: d f =100μm; liquid water content: LWC f =0.5g / m 3 ; Freezing time: t f =6min; freezing temperature: T f =252K.

[0127] The calculated experimental parameters of the model are: chord length: L m =0.3m; flight speed: V m =123.4m / s; droplet diameter: d m =58μm; liquid water content: LWC m =0.286g / m 3 ; Freezing time: t f =271s; freezing temperature: T f =253K.

[0128] For the real flight condition of embodiment 3 and its corresponding test condition, Figure 5 , 6 The comparison charts of the normalized results are given respectively. Figure 5 is the comparison chart of normalized water droplet collection coefficient, Image 6 It is the comparison chart of the normalized icing shape. Fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com