Dispensing device

A technology of a glue dispensing device and a glue injection device is applied in the field of dialyzers, which can solve the problems of low production efficiency and low product qualification rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

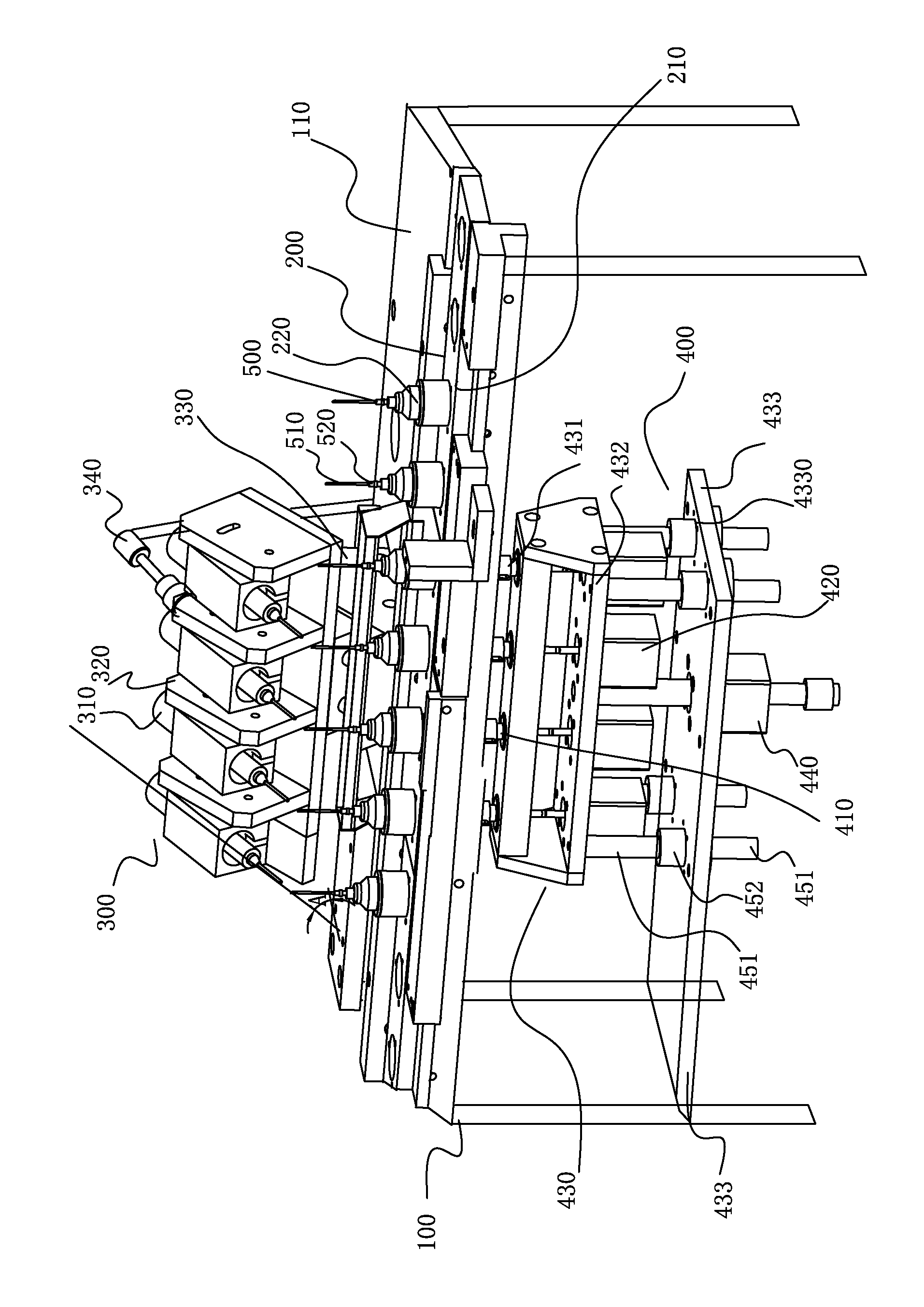

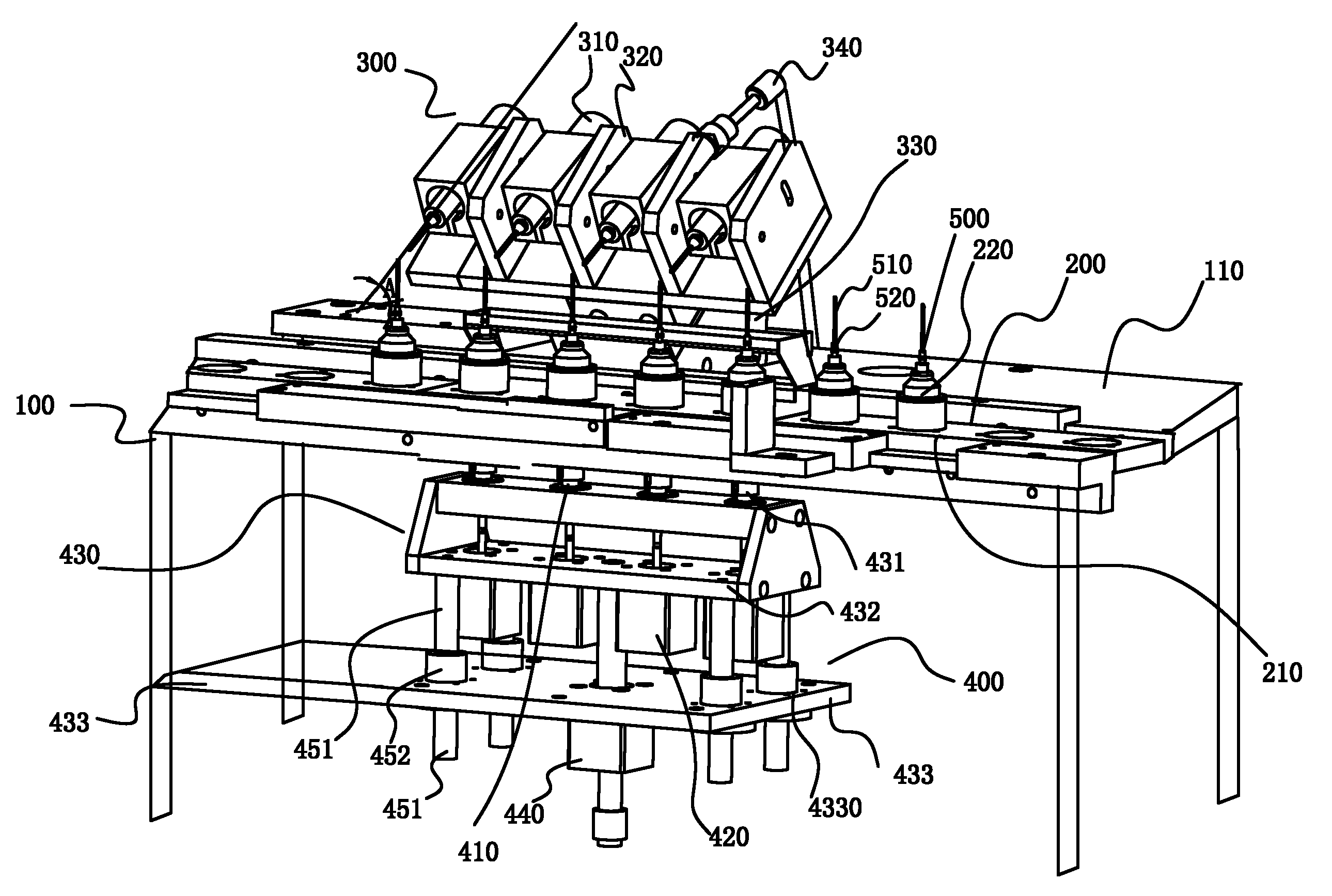

[0056] A dispensing device such as figure 1 As shown, a frame body 100, an automatic feeding device 200, a glue injection device 300, a rotating device 400 and a control device are provided.

[0057] The frame body 100 is used to carry the automatic feeding device 200, the glue injection device 300, and the rotating device 400. The automatic feeding device 200 transports the puncture needle 510 and the needle seat 520 that need to be glued to the corresponding position for glue injection. The delivered puncture needle 510 and needle base 520 are processed. During the glue injection process, the rotating device 400 rotates the automatic feeding device 200 so that the glue can be injected into the connection between the puncture needle 510 and the needle base 520 . The entire glue injection process is controlled by the control device to ensure the effective cooperation between the various parts.

[0058] The frame body 100 is provided with a substrate 110, the automatic feeding...

Embodiment 2

[0068] A dispensing device of the present invention, other mechanisms are the same as in Embodiment 1, the difference is that in this embodiment, the angle A between the axis where the glue injection tube 310 is located and the plane where the substrate 110 is located is 45°, not only The glue injection process is convenient and accurate, and the preparation is simple and convenient.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com