Method for preparing crosslinked hyaluronic acid microgel for tissue filling

A technology of cross-linked hyaluronic acid and microgel, which is applied in the fields of medical cosmetology and biomedicine, can solve problems not described, and achieve good biocompatibility, good stability, and long-term effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

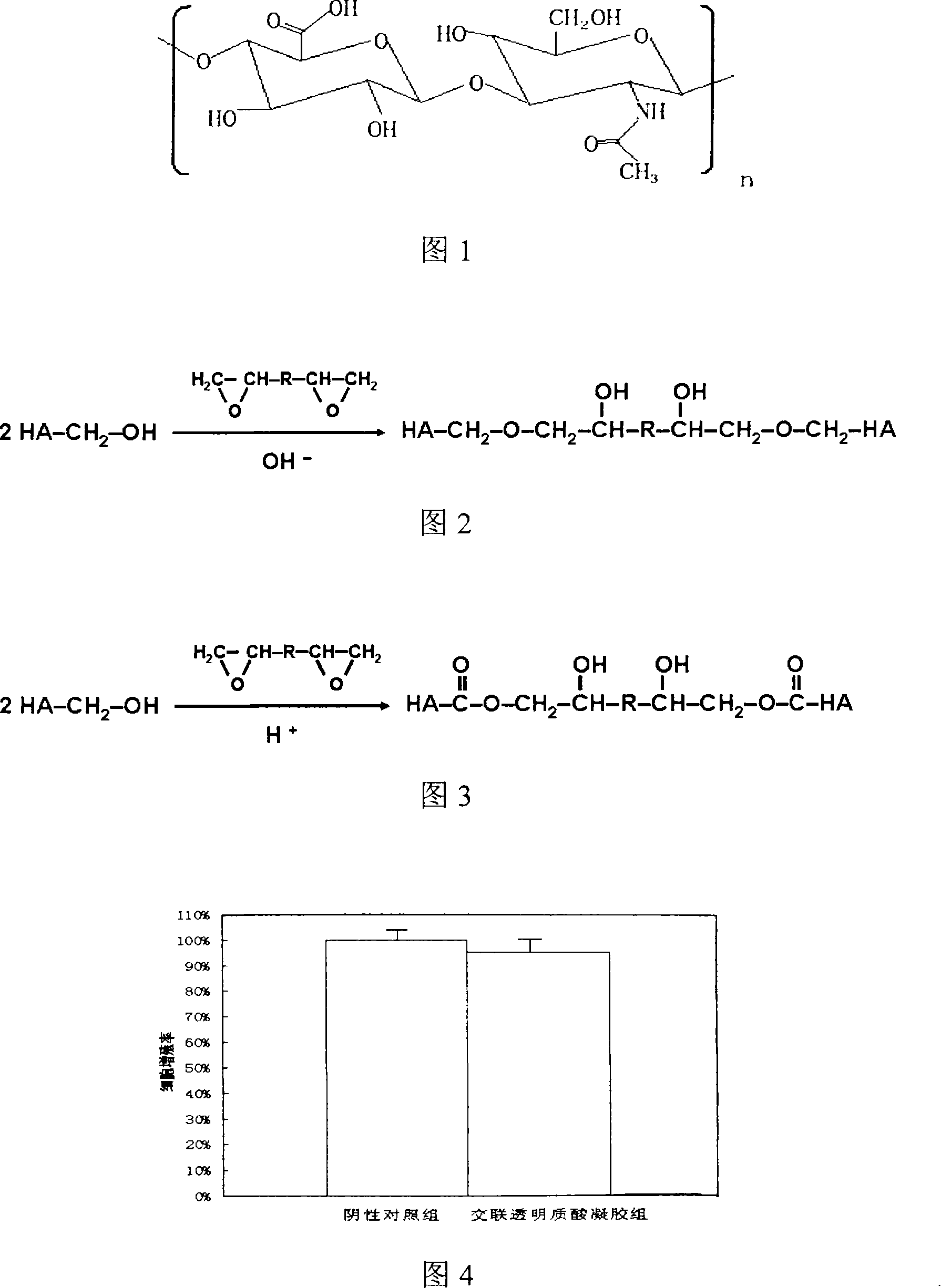

[0029]1.0g of sodium hyaluronate dry powder (molecular weight: 1,000,000 Daltons) derived from bacterial fermentation, whose structure is shown in Figure 1, was dissolved in 10ml of 0.2M NaOH solution, stirred to make it completely dissolved, and prepared into 10.0 % (w / v) hyaluronic acid alkaline solution, the reaction formula is shown in Figure 2, add 1.3g of butanediol diglycidyl ether, and stir well. Pour it into a 24-well plate for cell culture with a volume of about 2.9ml per well, and place it in a 35°C incubator for 6 hours to form cross-linked hyaluronic acid gel blocks of uniform size and regular shape. Take out the gel block, add it to 50ml of hydrochloric acid solution with a concentration of 0.1M, and place it at room temperature for 14 hours. The physiological balance solution was replaced 10 times, and the physiological balance solution used for dialysis was 500ml each time. Remove the physiological balance liquid, put the cross-linked hyaluronic acid gel block...

Embodiment 2

[0031] Dissolve 1.0g of sodium hyaluronate dry powder (molecular weight: 1,000,000 Daltons) derived from bacterial fermentation in 10ml of 0.5M NaOH solution, stir to dissolve completely, and prepare 10.0% (w / v) hyaluronic acid Alkaline solution, add 1.0 g of butanediol diglycidyl ether, and stir well. Pour it into a 24-well plate for cell culture with a volume of about 2.9ml per well, and place it in a 35°C incubator for 6 hours to form cross-linked hyaluronic acid gel blocks of uniform size and regular shape. Take out the gel block and add into 50ml of hydrochloric acid solution with a concentration of 0.1M, and stand at room temperature for 14 hours. Then pour off the hydrochloric acid solution, wash and dialyze with the physiological balance solution, and in the following 5 days, change the physiological balance solution 10 times, and the physiological balance solution used for dialysis is 500ml each time. Remove the physiological balance liquid, put the cross-linked hyal...

Embodiment 3

[0033] Dissolve 1.0g of sodium hyaluronate dry powder (molecular weight: 1.2 million Daltons) derived from bacterial fermentation in 10ml of 0.2M NaOH solution, stir to dissolve completely, and prepare 10.0% (w / v) hyaluronic acid Alkaline solution, add 1.2 g of ethylene glycol diglycidyl ether, and stir well. Pour it into a 24-well plate for cell culture with a volume of about 2.9ml per well, and place it in a 37°C incubator for 4 hours to form cross-linked hyaluronic acid gel blocks of uniform size and regular shape. The gel block was taken out, added to 50ml of hydrochloric acid solution with a concentration of 0.1M, and left at room temperature for 16 hours. Then pour off the hydrochloric acid solution, wash and dialyze with the physiological balance solution, and in the following 5 days, change the physiological balance solution 10 times, and the physiological balance solution used for dialysis is 500ml each time. Remove the physiological balance liquid, put the cross-lin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| storage modulus | aaaaa | aaaaa |

| complex viscosity | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com