Electronic component connecting method and joined body

A technology of electronic components and connection methods, applied in the direction of electrical component connection, conductive connection, conductive adhesive connection, etc., can solve problems such as poor conduction, damage to insulating coating, and low connection strength of electronic components, and achieve reliable conduction high performance and low on-resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

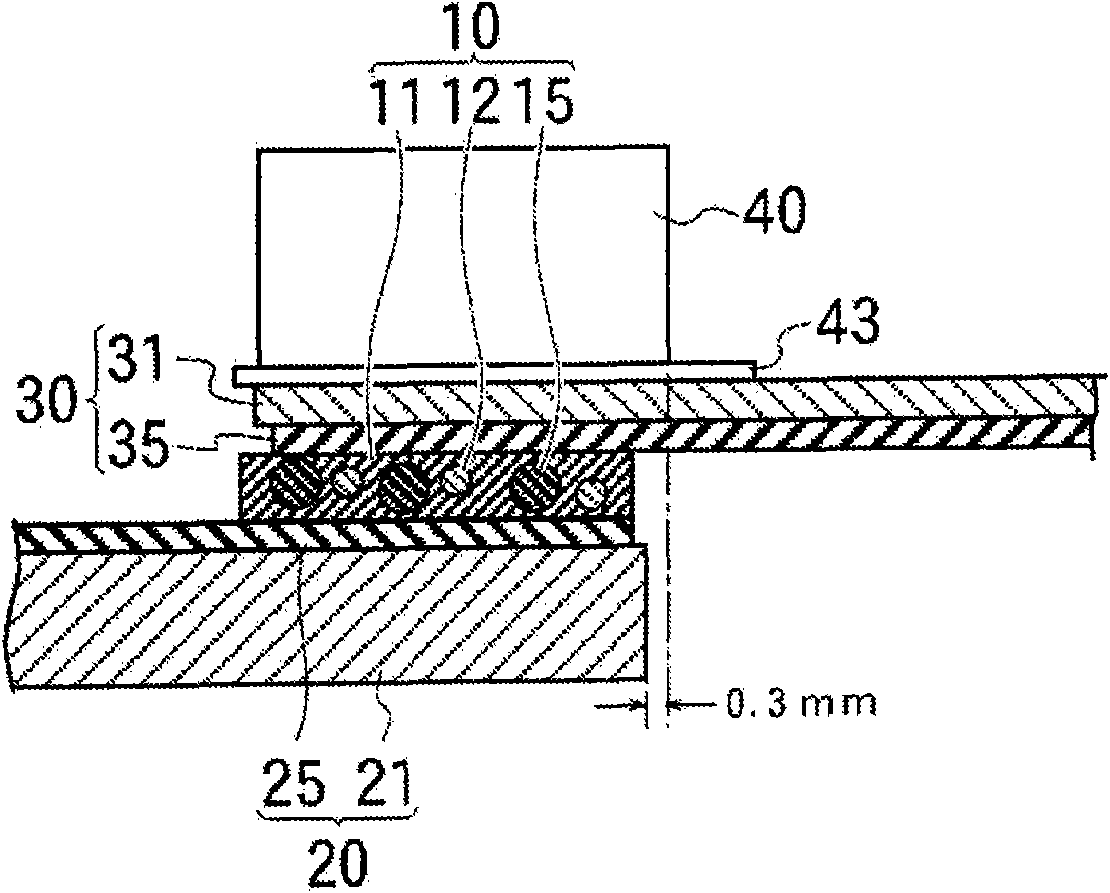

[0155] In Example 2 and Example 4, the types of insulating particles are different, but the results of "on-resistance", "short-circuit occurrence rate", and "catch number judgment" do not change regardless of each. Therefore, as long as the particle size of the deformed conductive particles is equal to or greater than the particle size of the insulating particles, a bonded body with high conduction reliability can be obtained regardless of the type of insulating particles.

Embodiment 1

[0156] Compared with Comparative Example 1, Example 1 has a lower incidence of short circuits, but the incidence of short circuits is higher than that of other examples. In Example 1, the content (total volume) of insulating particles is very small, only 0.05 times the content (total volume) of conductive particles. Therefore, in order to more reliably prevent short circuits, it is necessary to increase the content of insulating particles More than 0.05 times (volume ratio) of conductive particles.

[0157] In addition, Example 3 obtained excellent results both in terms of the short-circuit occurrence rate and the number of catches, but the on-resistance was higher than the other examples.

Embodiment 3

[0158] In Example 3, the content (total volume) of the insulating particles was too large and was 2.5 times the content (total volume) of the conductive particles. Therefore, the removal of the adhesive 11 from between the aluminum terminal and the copper terminal was poor. The on-resistance increases, resulting in poor continuity. Therefore, in order to prevent poor conduction, it is necessary to control the insulating particles to less than 2.5 times (volume ratio) of the conductive particles.

[0159] In the foregoing, although only the case where the electronic component 30 is temporarily fixed after temporarily pasting the anisotropic conductive adhesive 10 on the substrate 20 has been described, the present invention is not limited to this, and anisotropic conductive The adhesive 10 is temporarily attached to the electronic component 30, and may also be temporarily attached to the electronic component 30 and the substrate 20 at the same time. In addition, the same crimping...

PUM

| Property | Measurement | Unit |

|---|---|---|

| coating thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com