Anisotropic conductive adhesive composition and anisotropic conductive film comprising the same

An anisotropic, conductive film technology, applied in the direction of conductive adhesives, elastic polymer dielectrics, adhesives, etc., can solve the problems that free radical curing materials are difficult to meet electronic materials, and it is difficult to ensure high reliability circuit connections.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

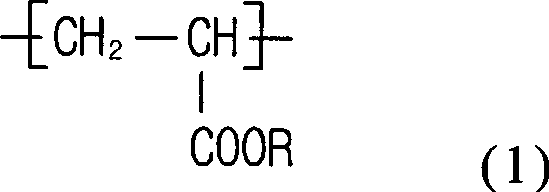

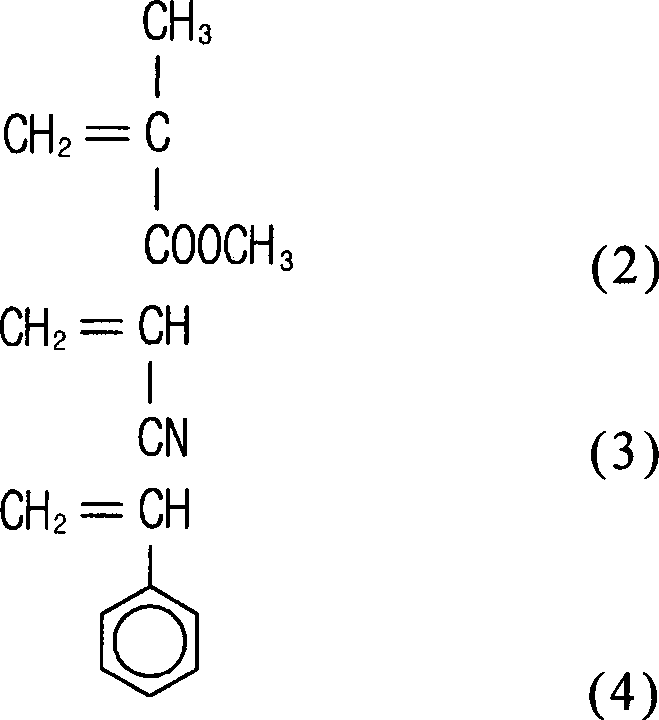

Method used

Image

Examples

Embodiment 1

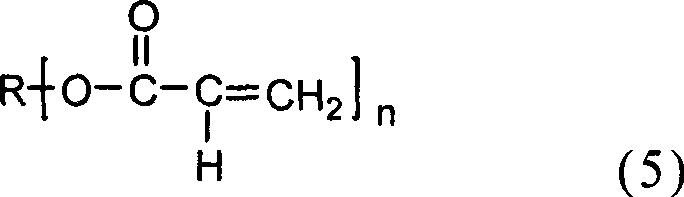

[0069] 55.5 wt% acrylic rubber (SG80H, Nagase Chemtex Corp. (Japan)) dissolved in methyl ethyl ketone (solid content = 20%), 18.5 wt% bisphenol A-type ring dissolved in methyl ethyl ketone (solid content = 60%) Oxygen acrylate resin (weight-average molecular weight=7,500, VR60, Showa Highpolymer Co., LTD. (Japan)), 18.5 wt% bisphenol A type epoxy acrylate resin (weight-average molecular weight=2,500) of general formula 7, 1.1 wt% of 2-methacryloxyethyl acid phosphate, 1.5 wt% of pentaerythritol triacrylate, dissolved in toluene (solid content = 10%) 0.4 wt% of lauroyl peroxide, dissolved in toluene 1.2 wt% benzoyl peroxide in medium (solid content=10%), and 3.3 wt% nickel particles (T110, Inco) were mixed together to prepare an anisotropic conductive adhesive composition.

[0070]

Embodiment 2

[0072] 45.7 wt% of acrylic rubber (SG80H, Nagase Chemtex Corp. (Japan)) dissolved in methyl ethyl ketone (solid content = 20%), 22.9 wt% of bisphenol A-type rubber dissolved in methyl ethyl ketone (solid content = 60%) Epoxy acrylate resin (weight average molecular weight=7,500, VR60, Showa Highpolymer Co., LTD. (Japan)), the bisphenol A type epoxy acrylate resin (weight average molecular weight=2,500) of 22.9wt% general formula 7, 1.4wt% of 2-methacryloyloxyethyl acid phosphate, 1.8wt% of pentaerythritol triacrylate, 0.5wt% of lauroyl peroxide dissolved in toluene (solid content=10%), dissolved in 1.5 wt% benzoyl peroxide in toluene (solid content = 10%), and 3.3 wt% nickel particles (T110, Inco) were mixed together to prepare an anisotropic conductive adhesive composition.

Embodiment 3

[0074] 30.0 wt% acrylic rubber (SG80H, Nagase Chemtex Corp. (Japan)) dissolved in methyl ethyl ketone (solid content = 20%), 30.0 wt% bisphenol A-type ring dissolved in methyl ethyl ketone (solid content = 60%) Oxygen acrylate resin (weight average molecular weight=7,500, VR60, Showa Highpolymer Co., LTD. (Japan)), 30.0 wt% bisphenol A type epoxy acrylate resin (weight average molecular weight=2,500) of general formula 7, 1.8 wt% 2-methacryloyloxyethyl phosphate, 2.4 wt% pentaerythritol triacrylate dissolved in toluene (solids content = 10%) 0.6 wt% lauroyl peroxide dissolved in toluene 1.9 wt% benzoyl peroxide (solid content=10%), and 3.3 wt% nickel particles (T110, Inco) were mixed together to prepare an anisotropic conductive adhesive composition.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com