Pressure-sensitive adhesive for optical film, pressure-sensitive adhesive optical film, production method thereof, and image display

A technology of optical film and manufacturing method, applied in the direction of film/sheet-like adhesive, adhesive type, pressure-sensitive film/sheet, etc., can solve the problem of inability to meet durability and other problems, achieve good durability and prevent falling off Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0185]

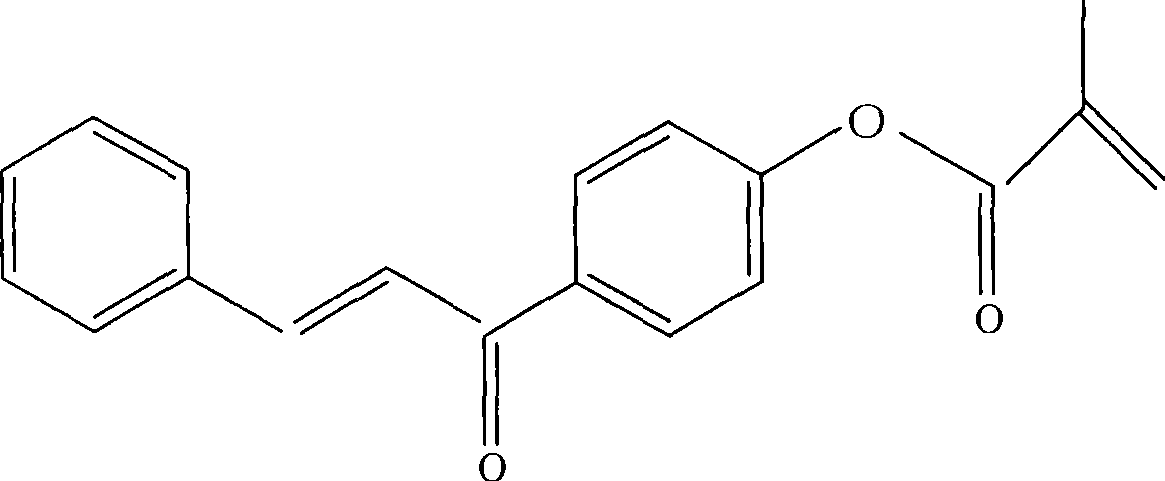

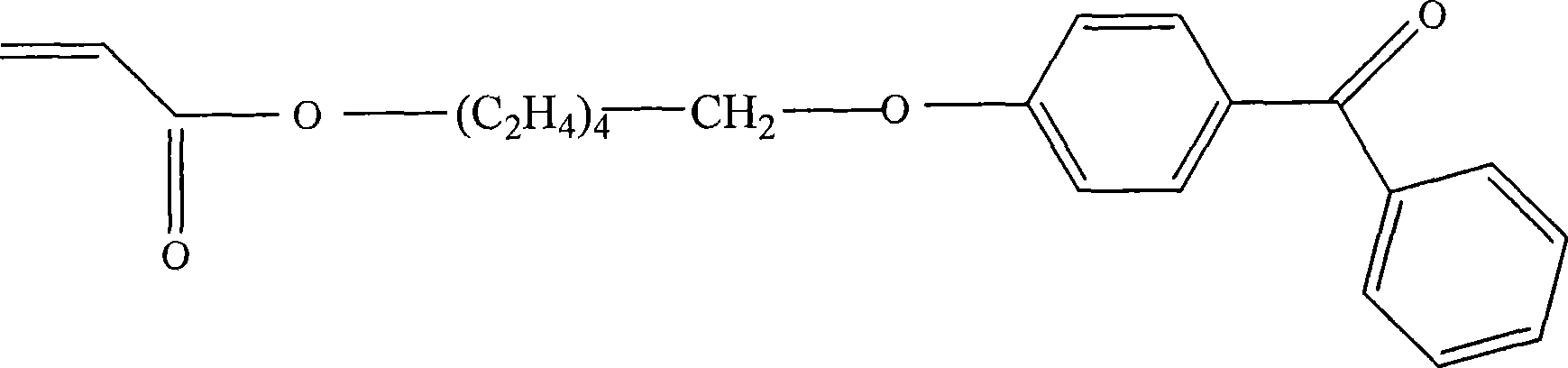

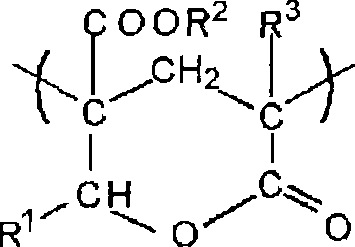

[0186] In a four-necked flask equipped with a stirring paddle, a thermometer, a nitrogen introduction tube, and a cooler, 95 parts of butyl acrylate, photocrosslinkable monomers (containing cinnamoyl monomers, AR monomers, etc.) , Japan Siberuhegner Co., Ltd.) 5 parts, 0.1 part of 2,2'-azobisisobutyronitrile as a polymerization initiator, and 200 parts of ethyl acetate were slowly stirred while nitrogen gas was introduced, and after nitrogen replacement, the The liquid temperature in the flask was maintained at around 60° C., and a polymerization reaction was performed for 6 hours to prepare an acrylic polymer solution. The weight average molecular weight of the acrylic polymer is 1.63 million.

[0187]

[0188] Ethyl acetate was further added to the acrylic polymer obtained above to prepare an acrylic polymer solution having a total solid content concentration of 30%. Next, 0.1 part of N-phenyl-γ-aminopropyltrimethoxysilane (manufactured by Shin-Etsu Chemical Co...

Embodiment 2~9

[0192] In Example 1, as shown in Table 1, at least one of the type and amount of monomer components used when preparing an acrylic polymer, or the drying temperature or activity of the adhesive layer when making an adhesive polarizing plate The irradiation amount of the energy ray was changed, except that, as in Example 1, an acrylic polymer solution was prepared, and an acrylic adhesive was prepared in the same manner. In addition, the cumulative light amount of ultraviolet irradiation was changed as shown in Table 1, except Otherwise, an adhesive polarizing plate with a release liner was produced in the same manner as in Example 1. Among them, the weight average molecular weights of the acrylic polymers obtained in each example are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com