Patents

Literature

116results about How to "Satisfactory resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

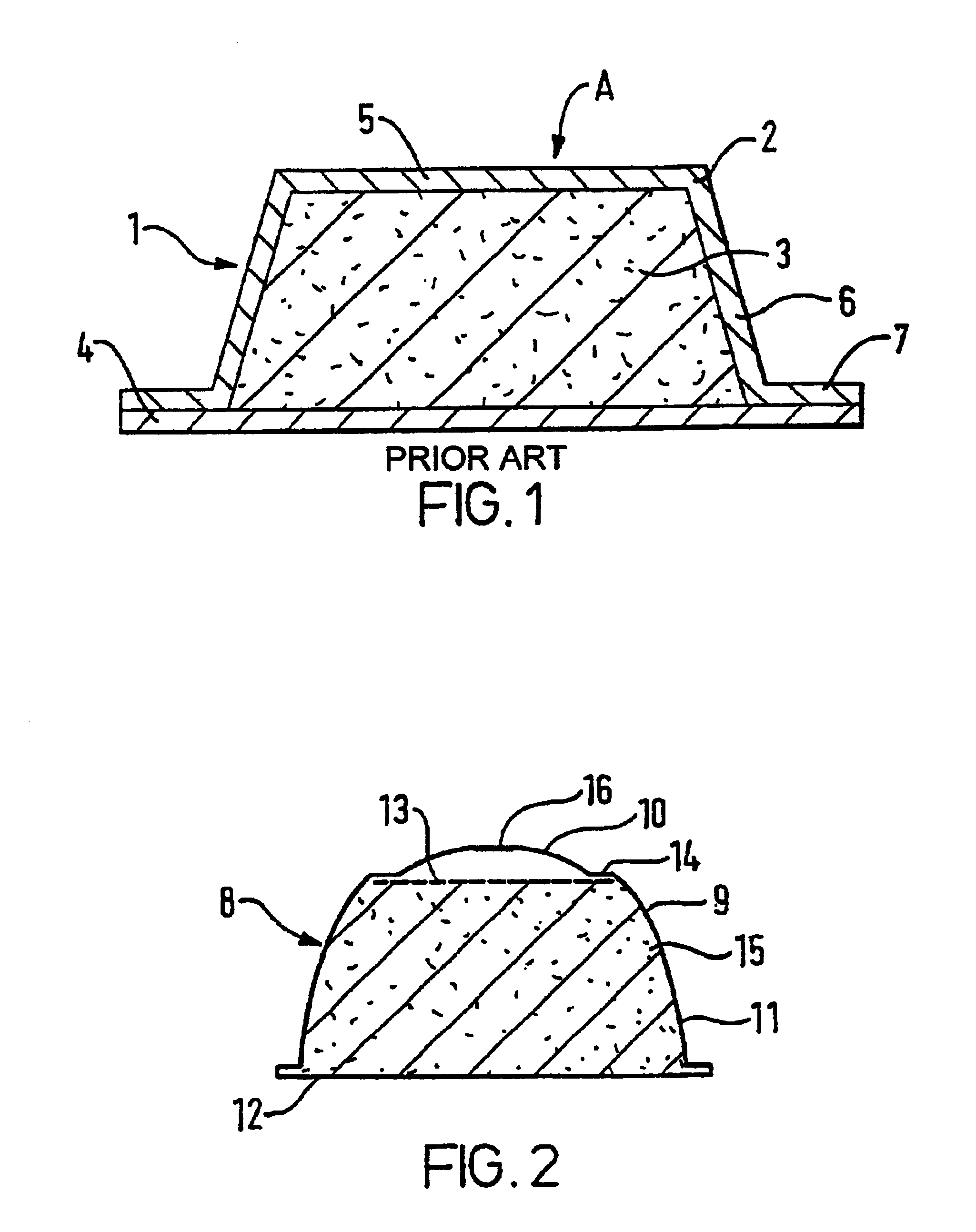

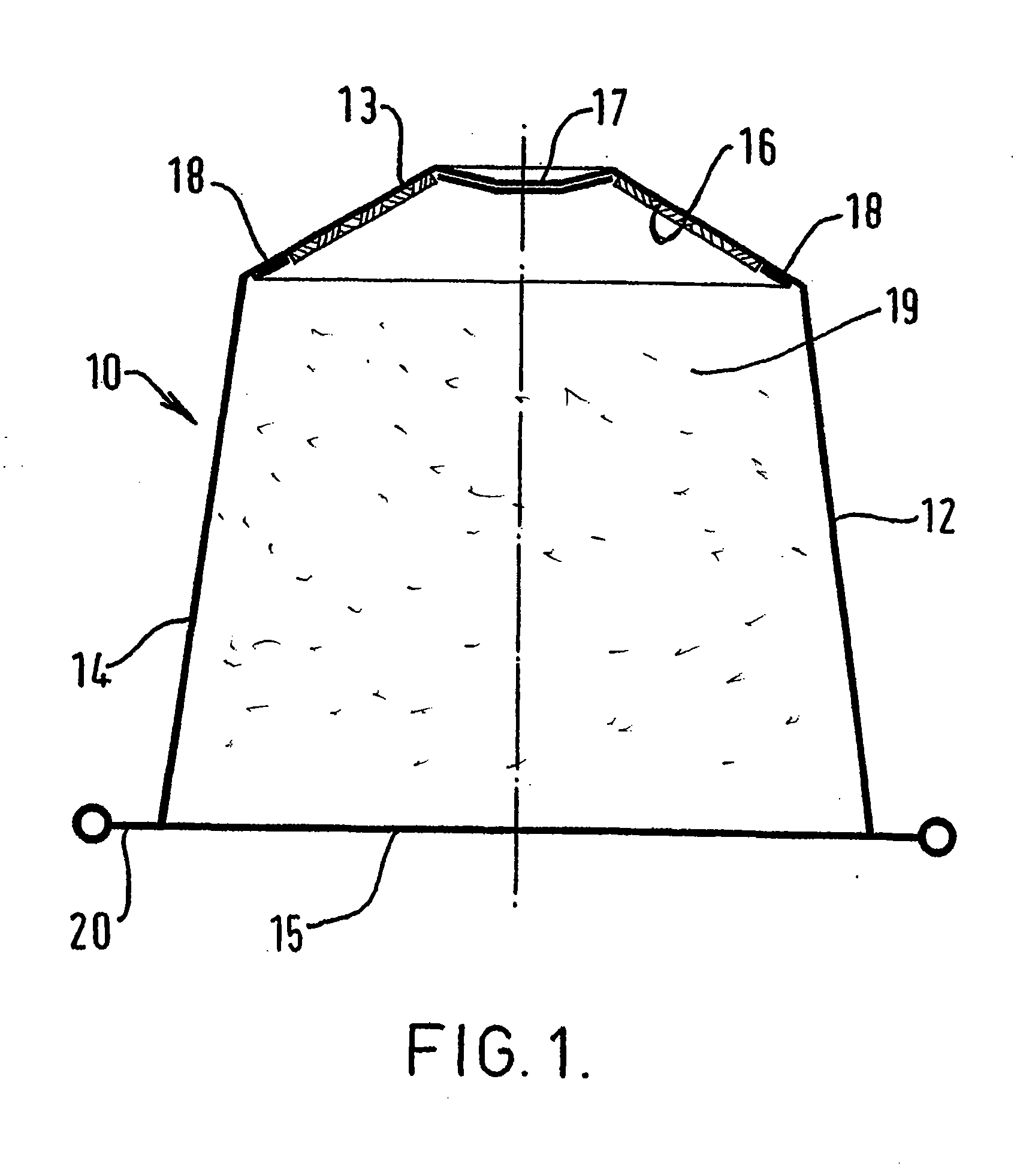

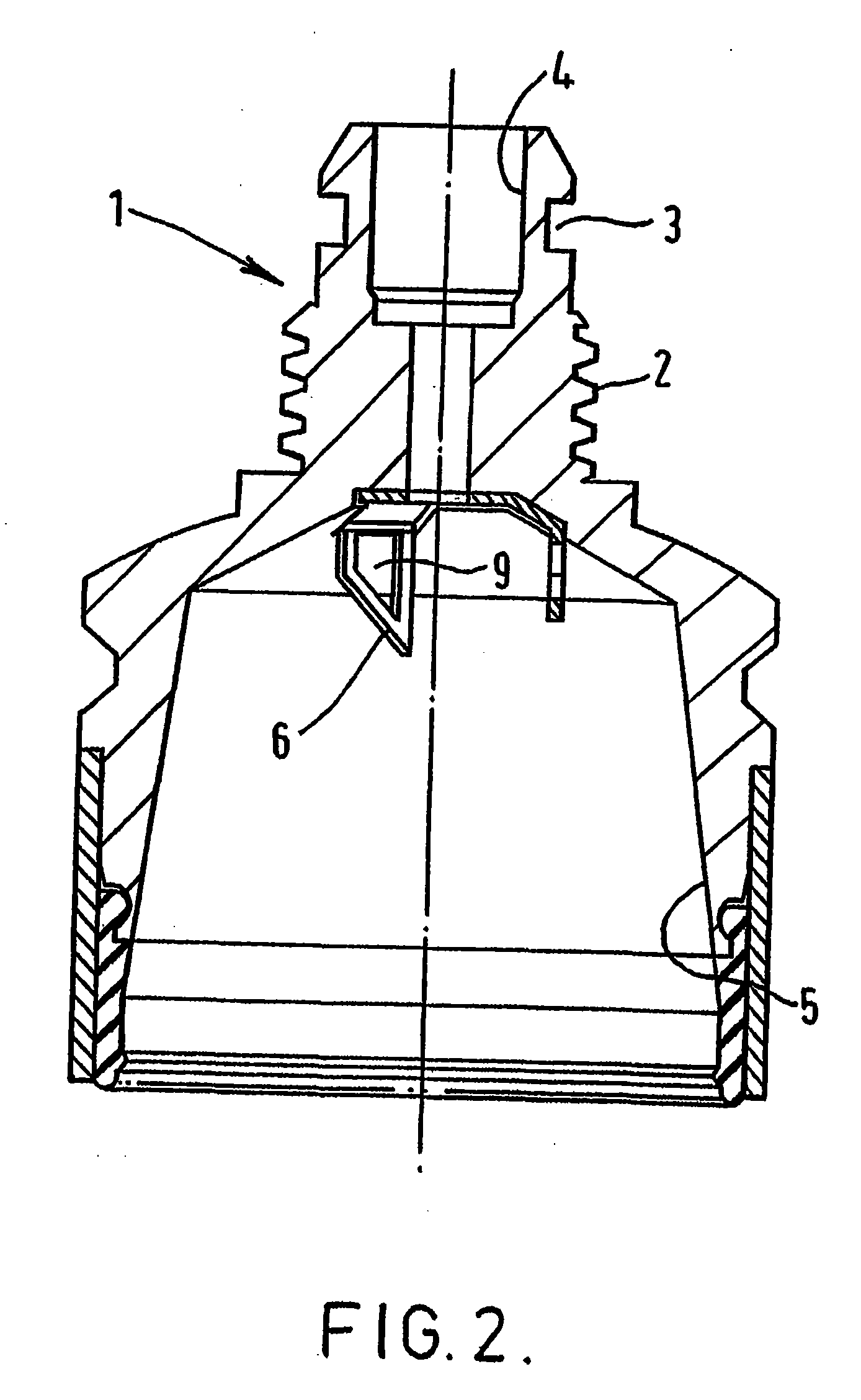

Sealed cartridge for making a beverage

InactiveUS6849285B2Easy to produceSatisfactory resistanceReady-for-oven doughsLiquid flow controllersBiotechnologyMechanical engineering

The invention relates to a sealed cartridge, provided to be extracted under pressure, containing a substance (15) for preparing a beverage, comprising a dish (9) with a bottom (10) and a side wall (11), having substantially the shape of a frustum of a cone, and a circular edge with a diameter greater than the bottom, and a cover (12) welded to the periphery of the edge of the dish, in which the cover (12) consists of a flexible material which is impermeable to oxygen, chosen from the group consisting of aluminum, an aluminum / plastic composite, an aluminum / plastic / paper composite, pure or multi-layer plastic, the said cartridge not comprising a filter or a weakening zone and the cover being intended to be torn only through the effect of the force of the extraction fluid when extraction starts, the said cartridge comprising, in the dish at the level of the bottom, a barrier (13) that is automatically resealable against leakage of the substance upon withdrawal of the fluid injection needle.

Owner:SOC DES PROD NESTLE SA

Graphic image fusion

InactiveUS7166249B2Satisfactory abrasion resistanceSatisfactory fade resistancePaper/cardboard articlesArtificial filament recoveryThermoplasticGraphics

An in-mold and in-line decorating method is disclosed which, using a single sheet layer, allows the placement of the highest possible quality graphics into the surface of products made from a variety of moldable thermoplastic, thermoset, and vulcanizable materials using a variety of molding processes. The methods also provide new or improved capabilities for product identification, safety, and serialized tracking.

Owner:TAYLOR COMM INC

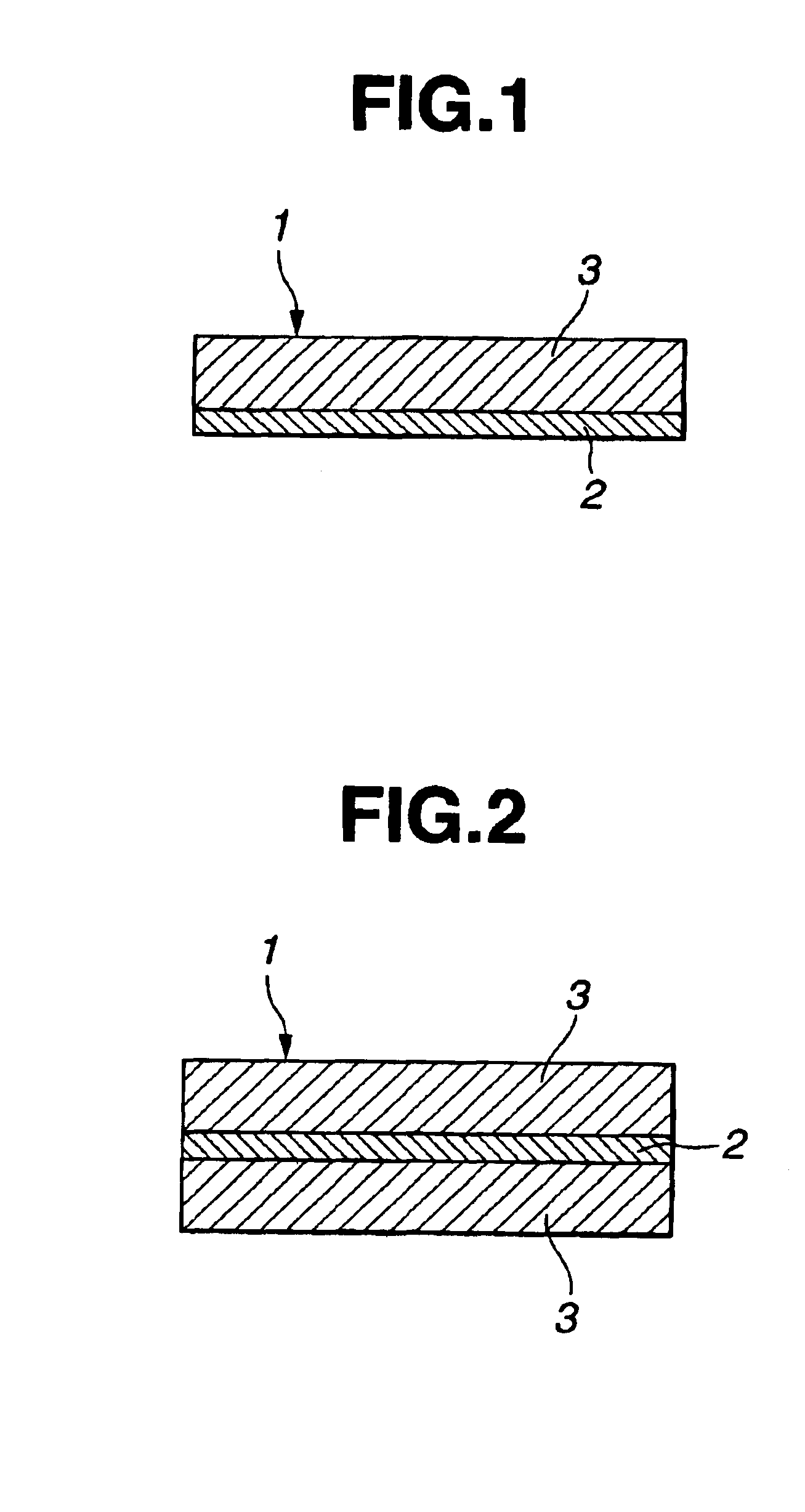

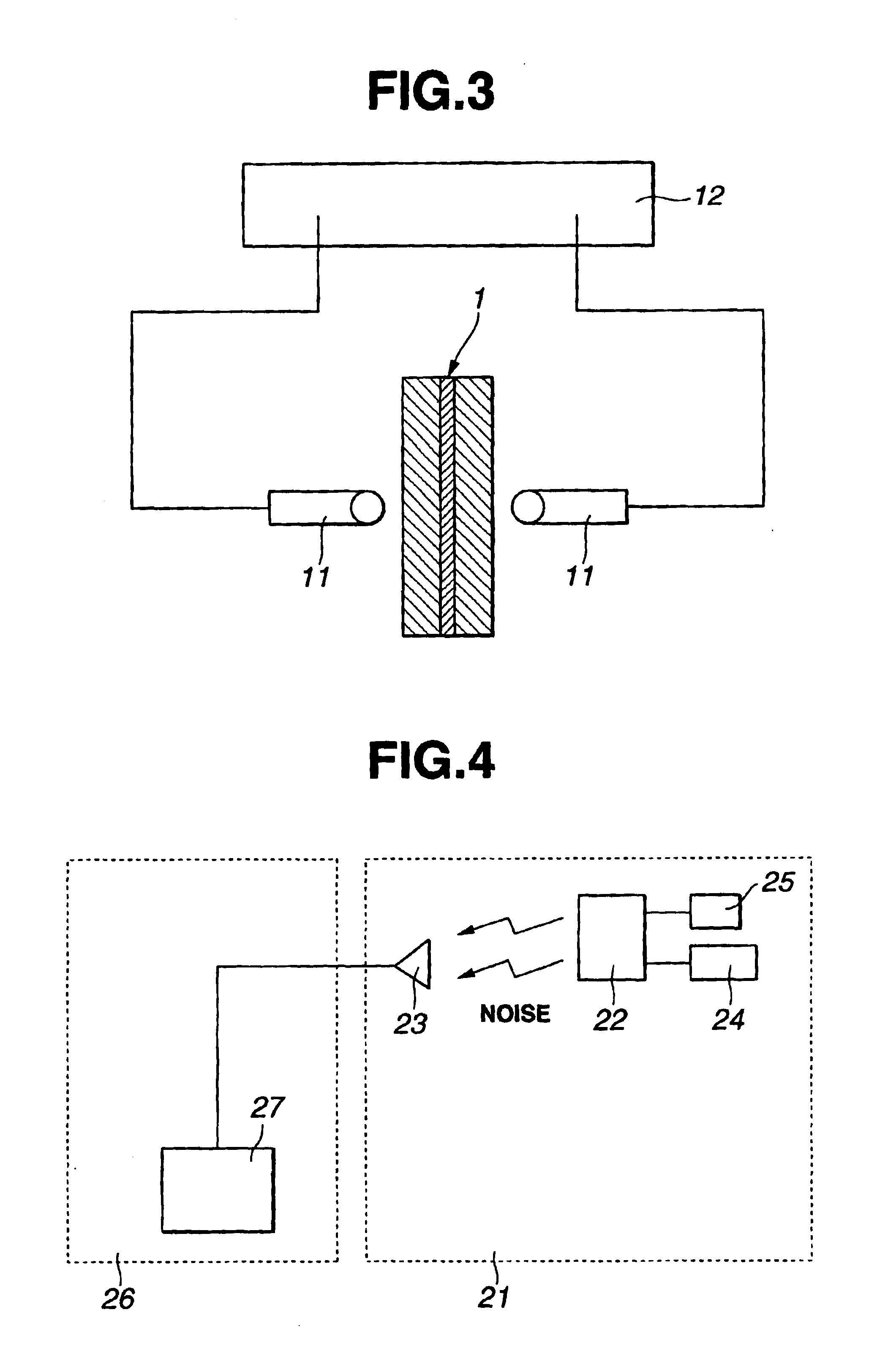

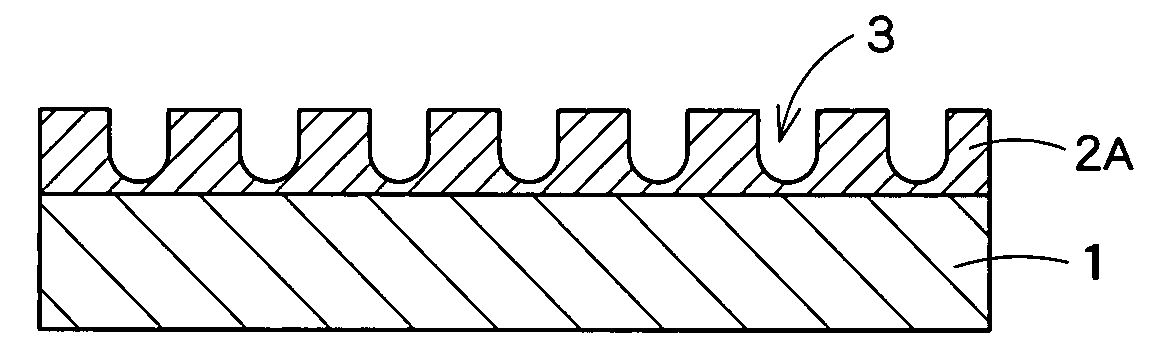

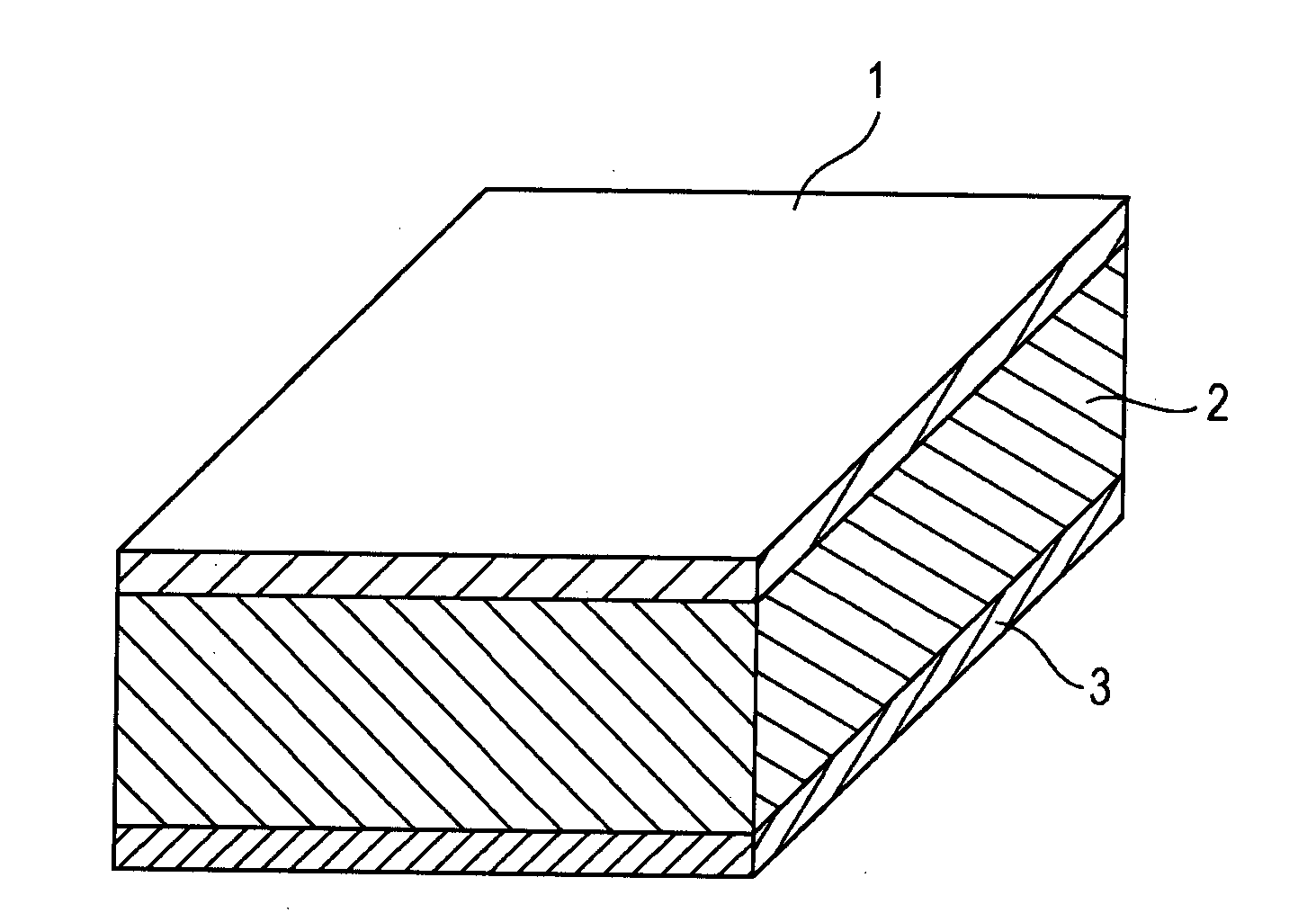

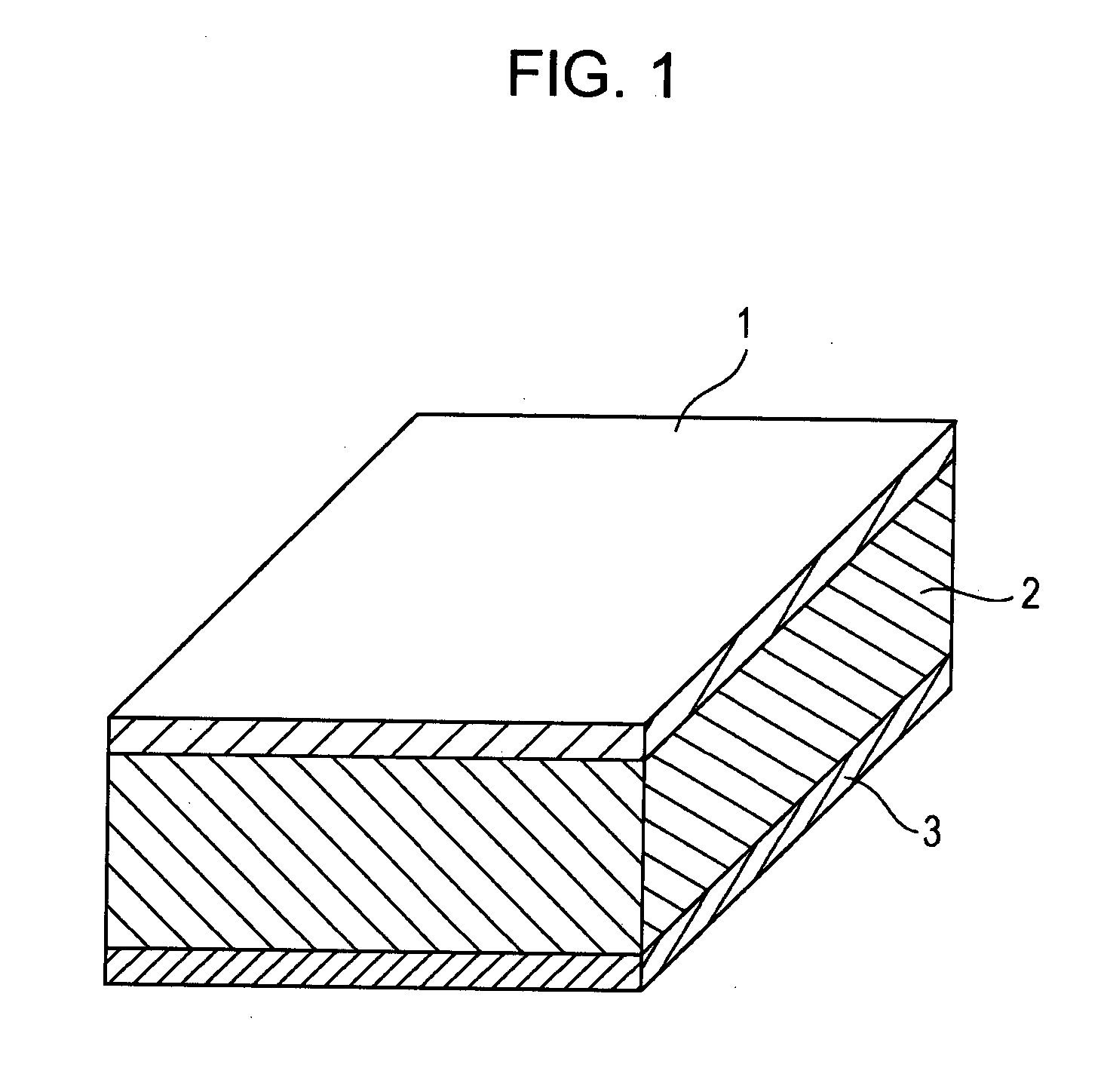

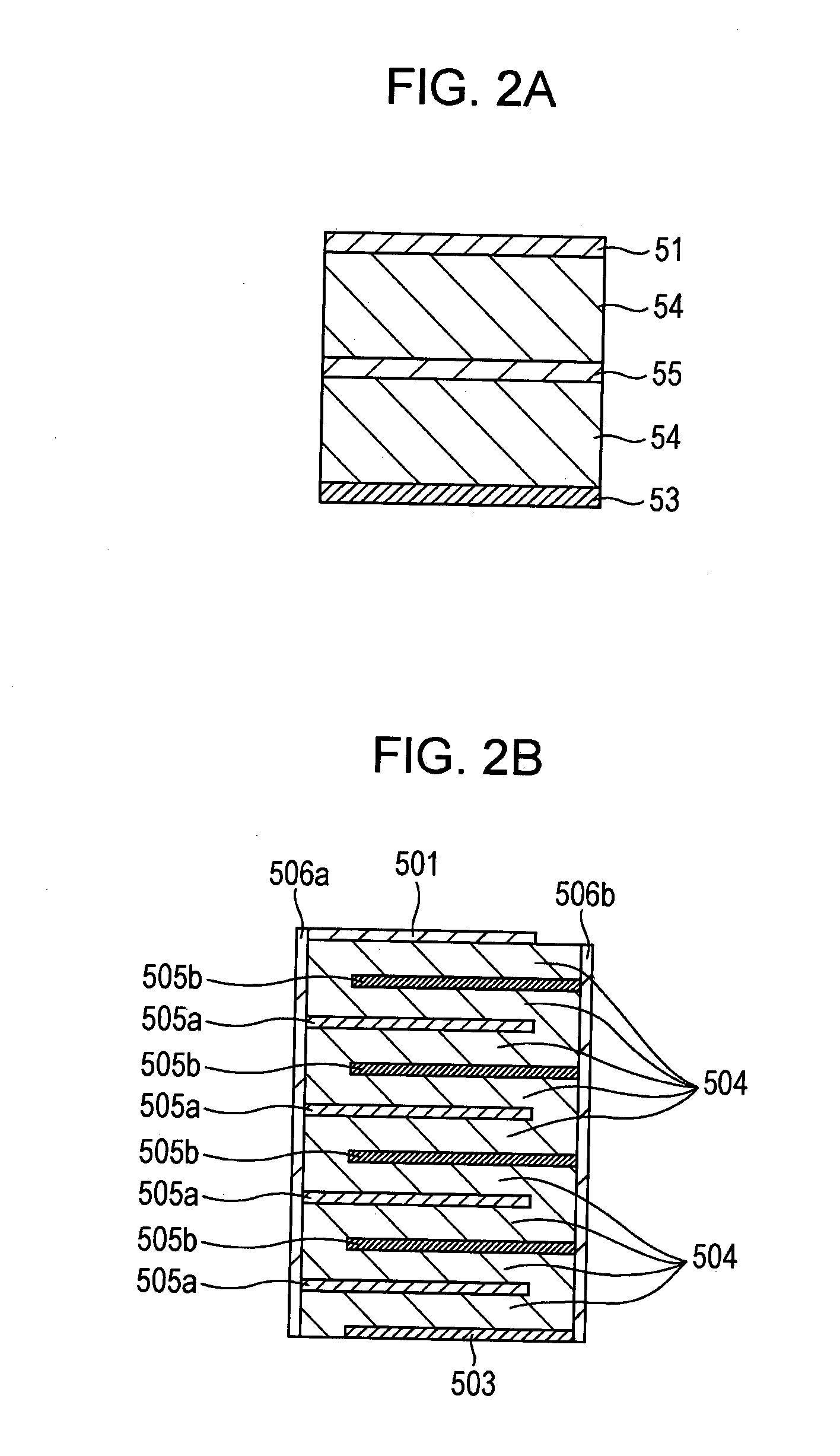

Electromagnetic wave absorber

InactiveUS6869683B2Satisfactory abilitySatisfactory adhesionMagnetic/electric field screeningConductive materialPhysicsPliability

An electromagnetic wave (EM) absorber is constructed by integrally laminating an EM-absorbing layer having an EM-absorbing filler dispersed in a silicone resin on at least one surface of an EM-reflecting layer having an electrically conductive filler dispersed in a silicone resin. It has satisfactory EM-absorbing and shielding abilities and is workable, flexible, weather resistant and heat resistant due to the nature of the silicone resin itself. The use of the silicone resin in both the EM-absorbing and reflecting layers ensures that a firm bond is established between the layers. In a preferred embodiment wherein a heat conductive filler is blended, the absorber has a satisfactory heat transfer ability as well.

Owner:SHIN ETSU CHEM CO LTD

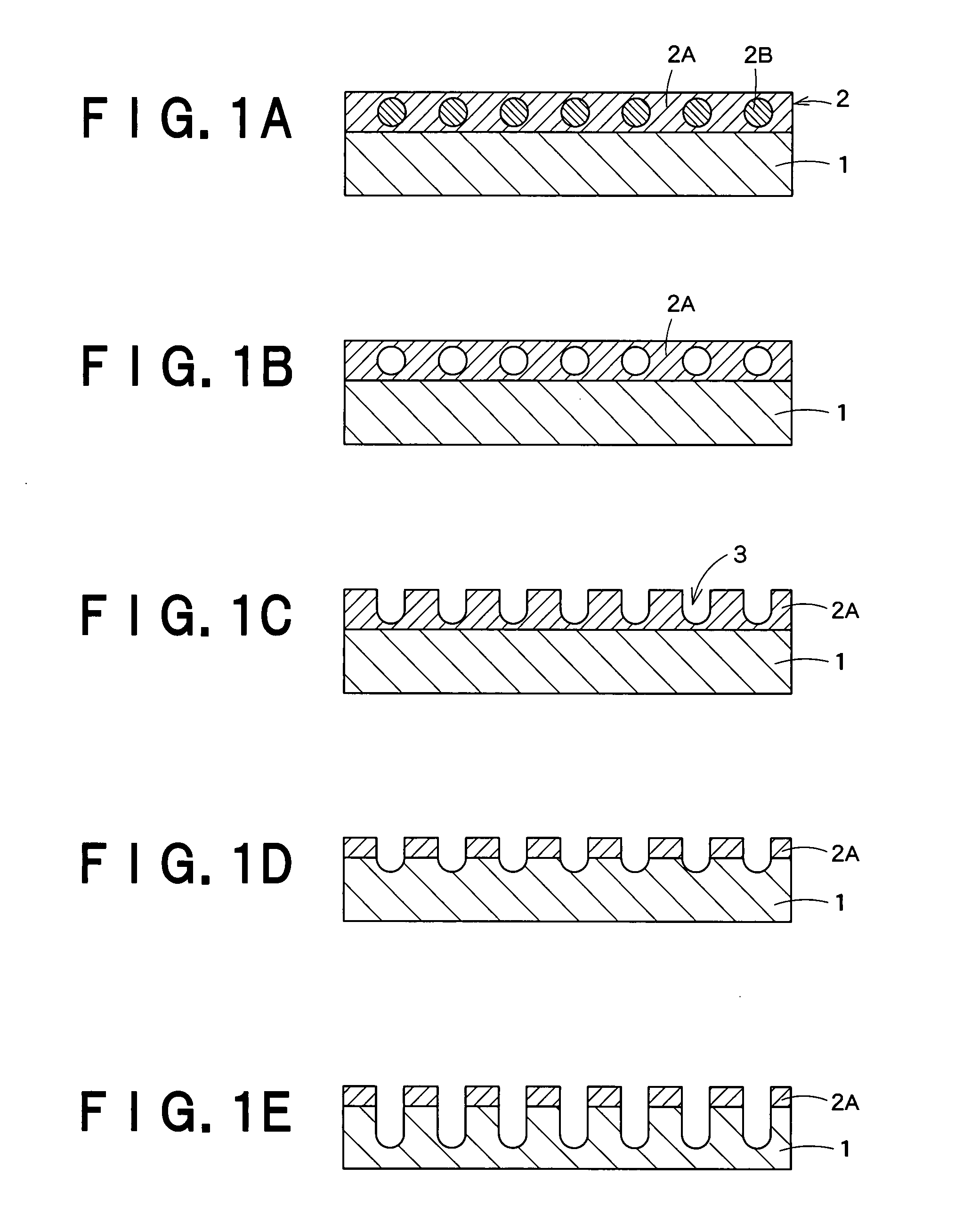

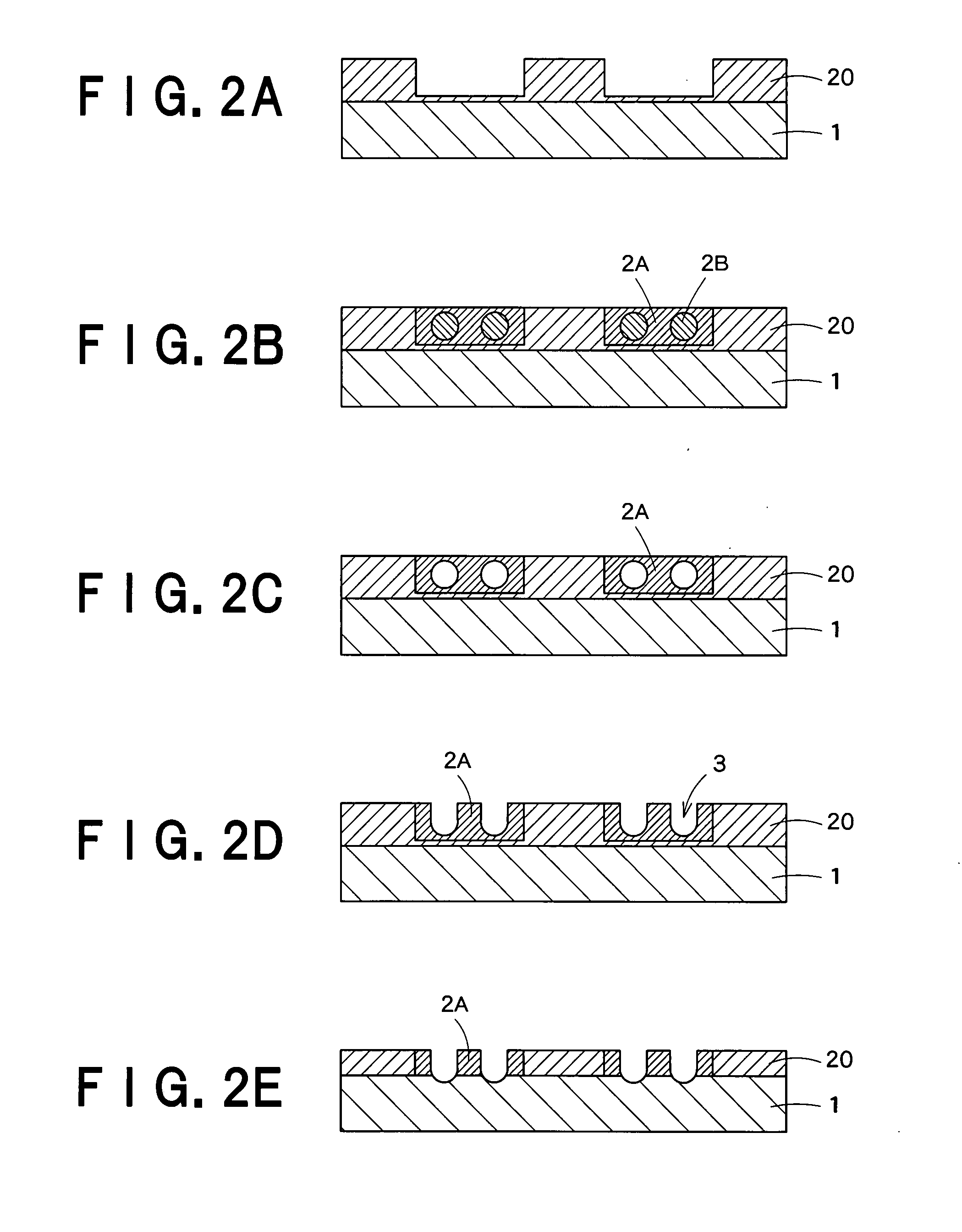

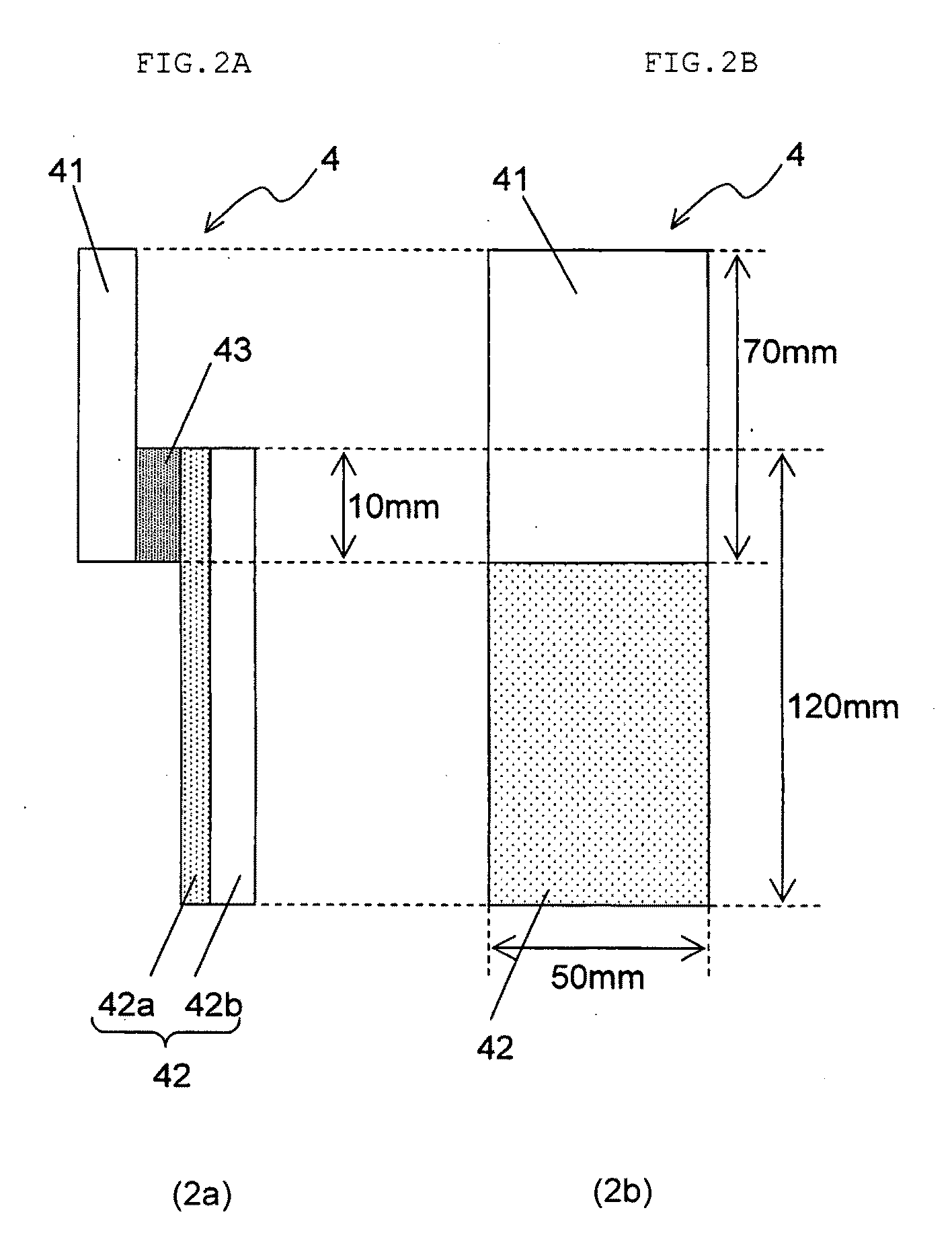

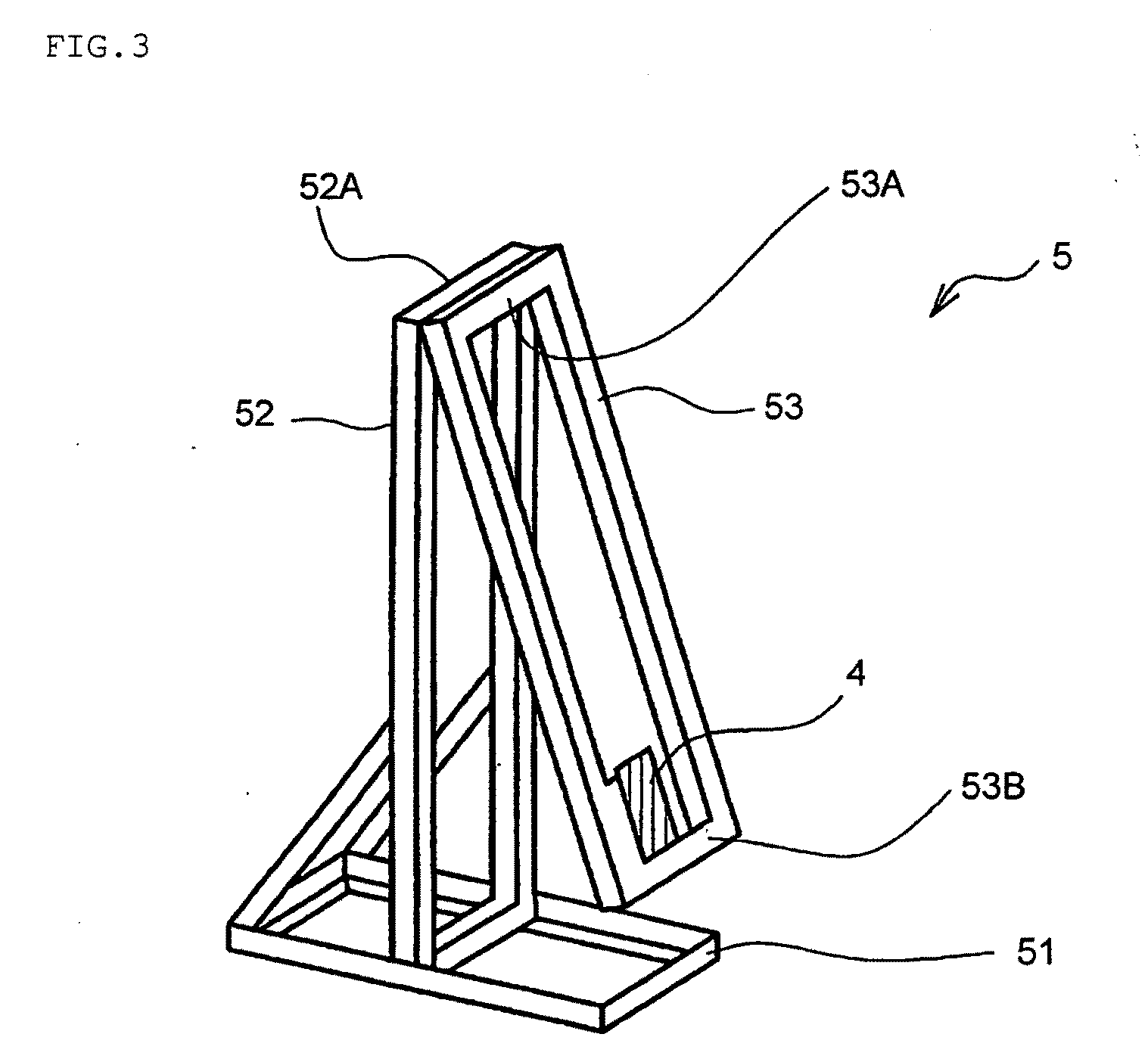

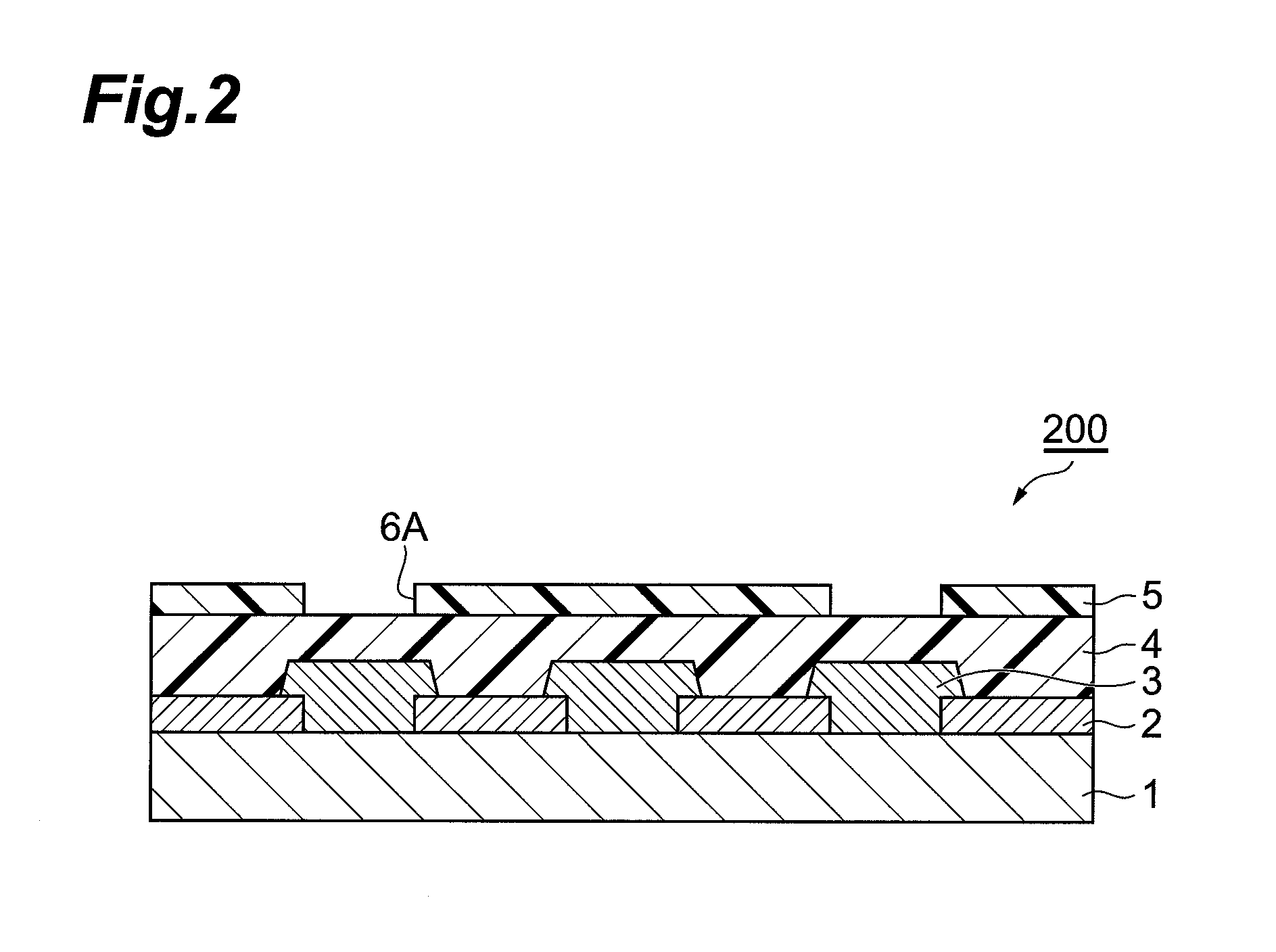

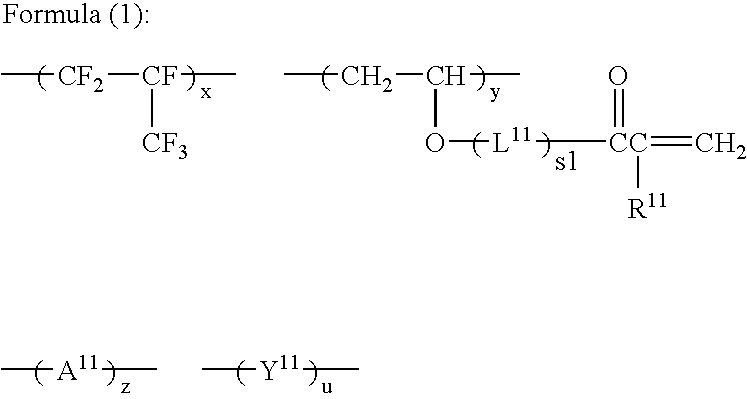

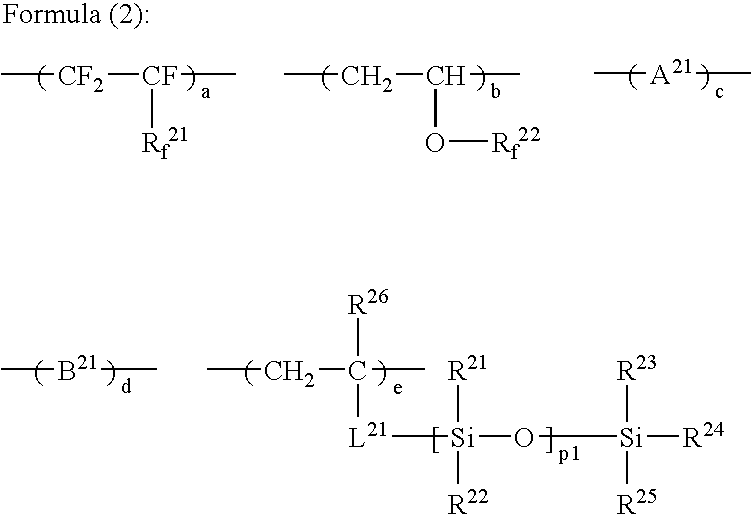

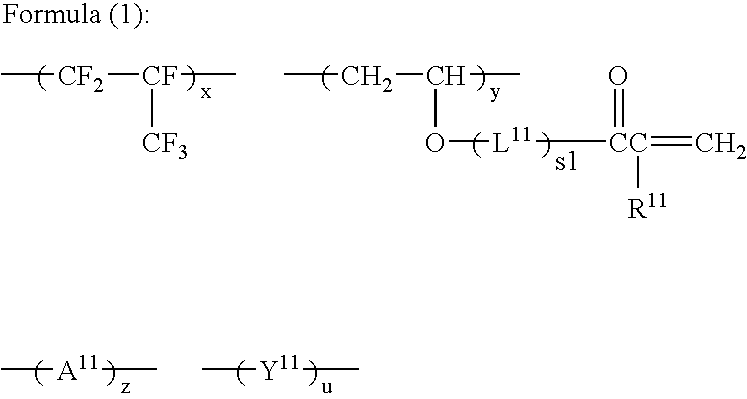

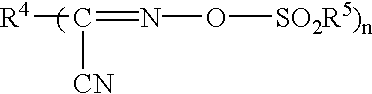

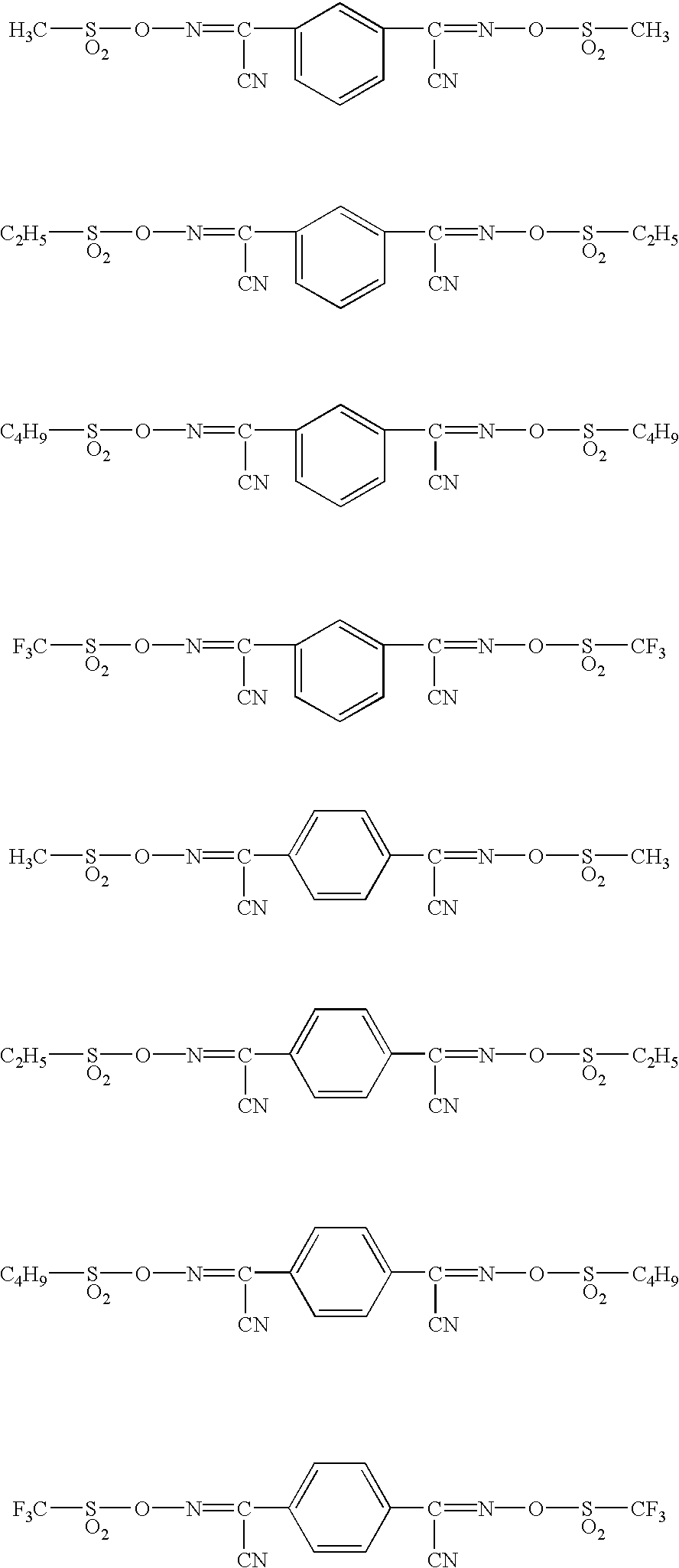

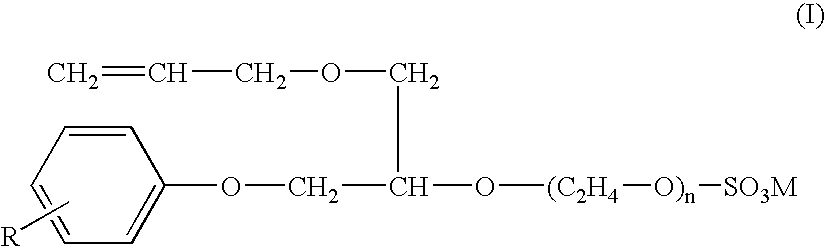

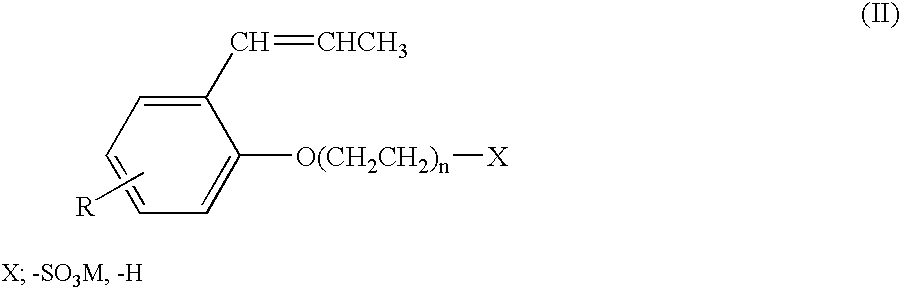

Method for pattern formation

InactiveUS20080041818A1Satisfactory etching resistanceHigh aspect ratioDecorative surface effectsNanoinformaticsOxygen plasmaSolvent

There is provided a method for pattern formation, including a step of coating a composition comprising a block copolymer, a silicon compound, and a solvent for dissolving these components onto an object to form a layer of the composition on the object, a step of subjecting the layer of the composition to self-organization of the block copolymer to cause phase separation into a first phase, in which the silicon compound is localized, having higher etching resistance by heat treatment or / and oxygen plasma treatment, and a second phase comprising a polymer phase and having lower etching resistance by heat treatment or / and oxygen plasma treatment, and thereby forming a pattern layer with a fine pattern, and a step of etching the object using as a mask the thus formed pattern layer.

Owner:KK TOSHIBA

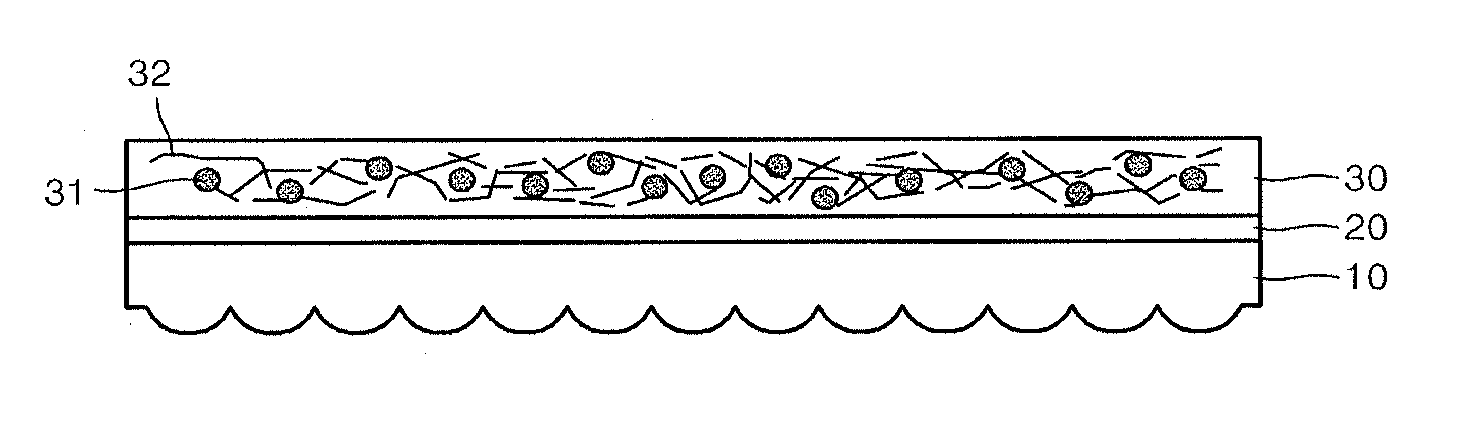

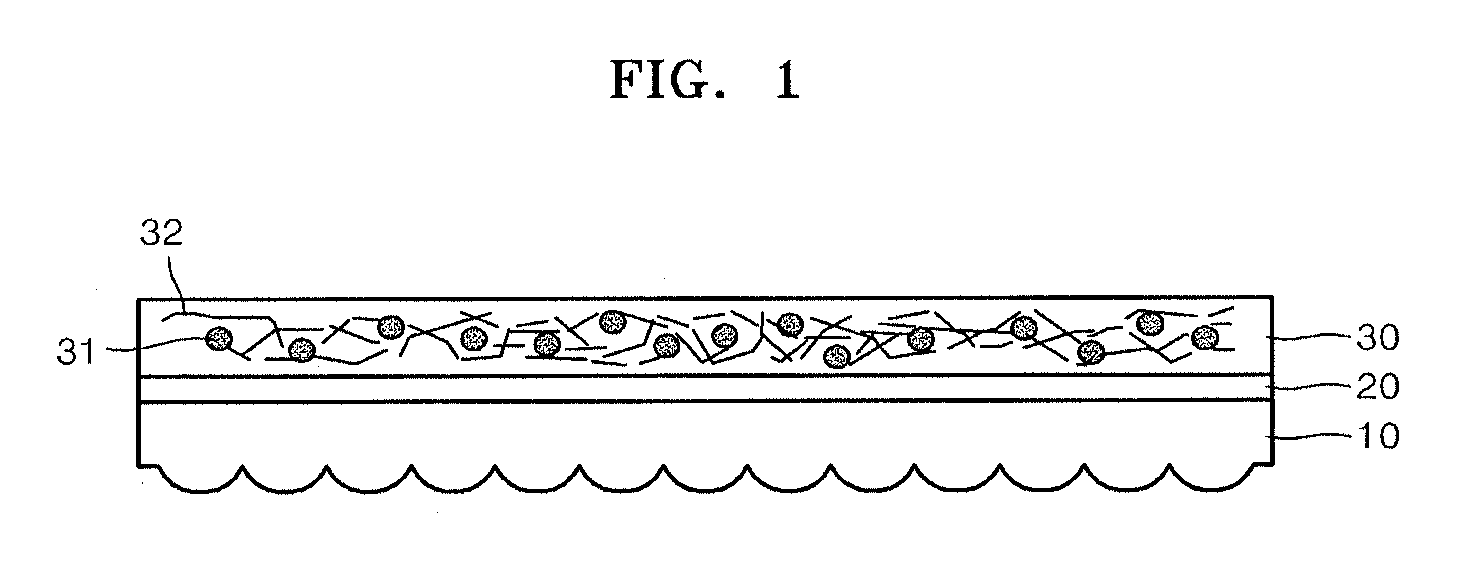

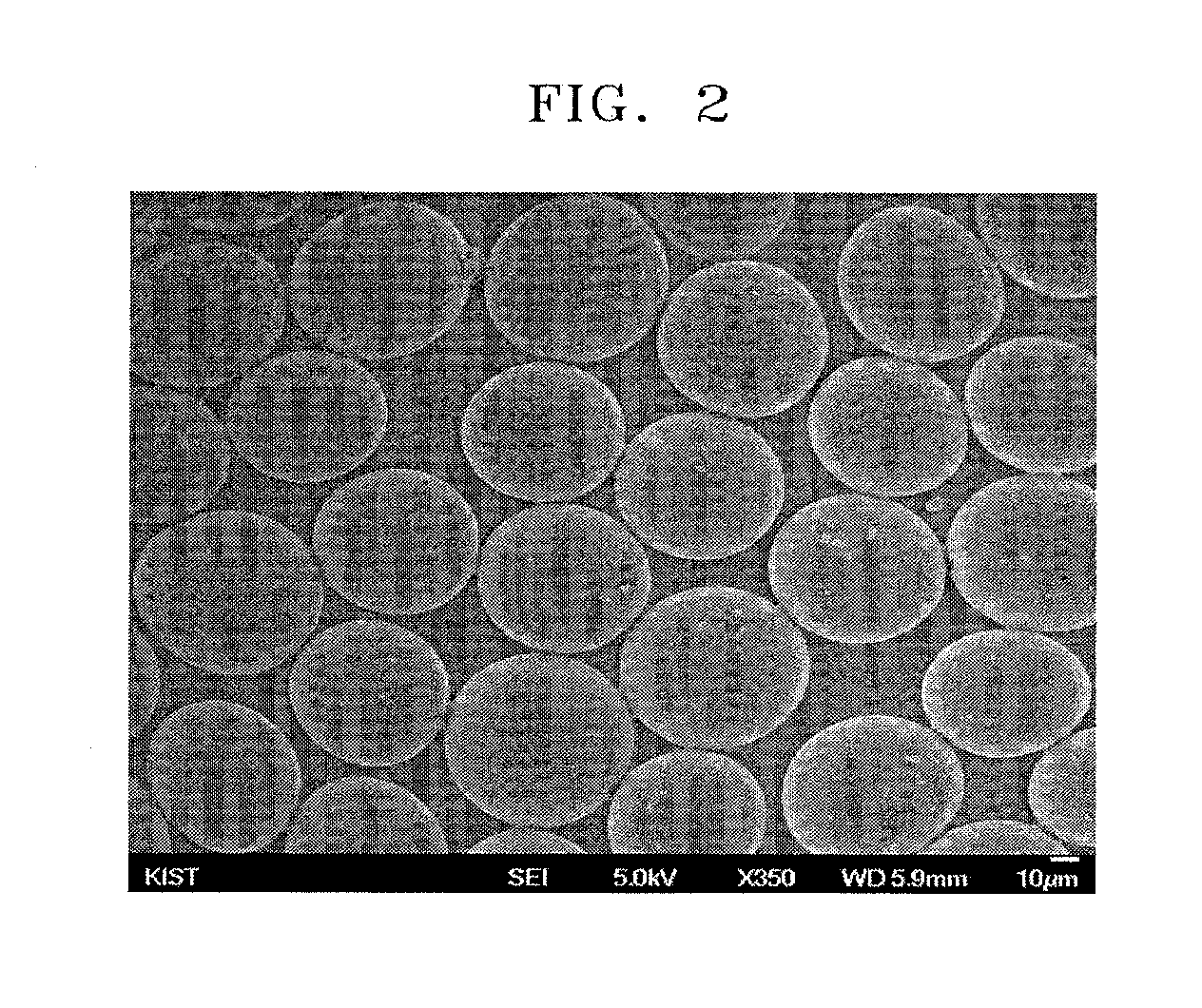

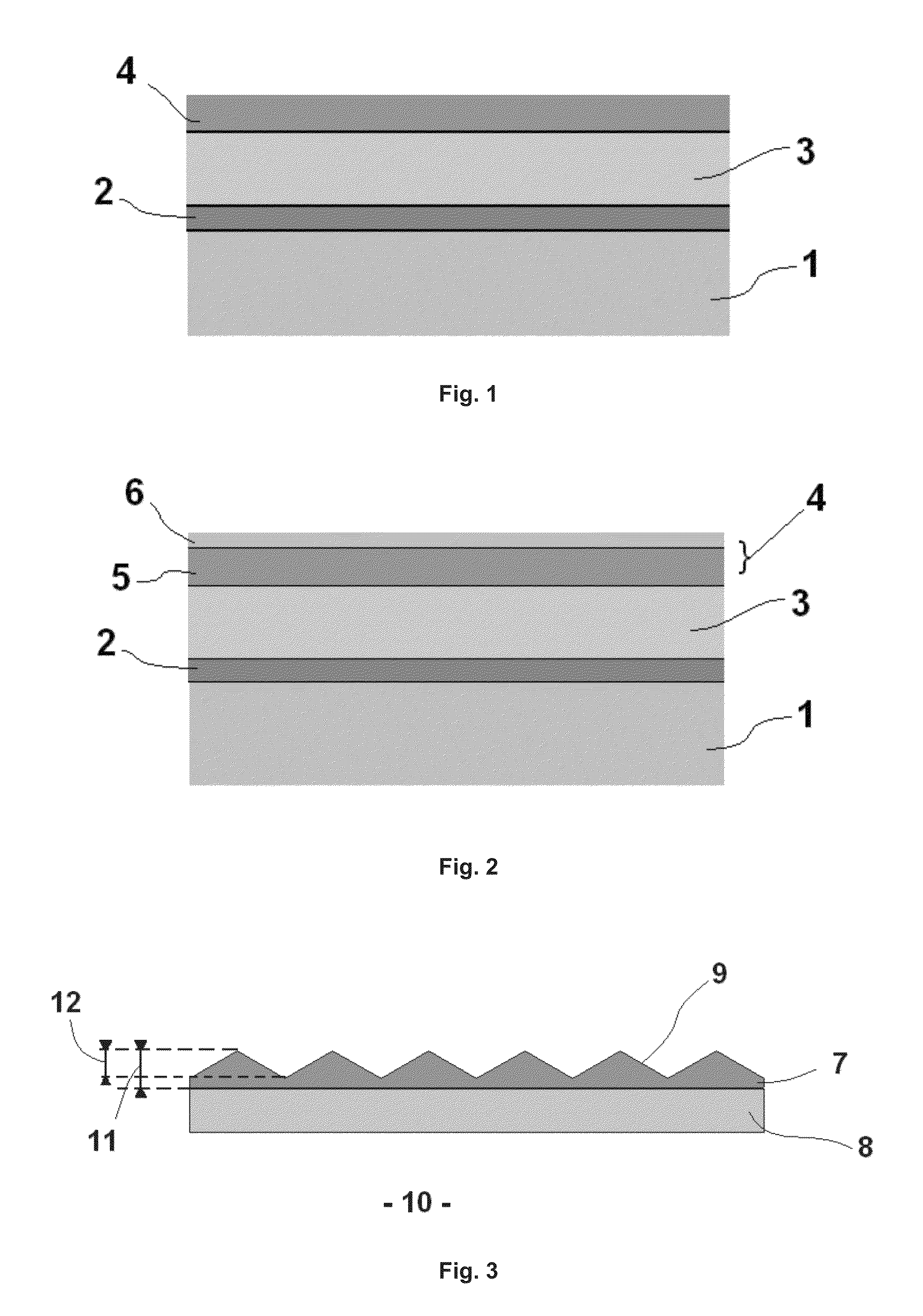

Color conversion luminescent sheet and fabrication method for the same

InactiveUS20120156436A1Satisfactory durabilitySatisfactory resistanceSynthetic resin layered productsSolid-state devicesNanofiberOptoelectronics

A color conversion luminescent sheet and a method of preparing the same, the color conversion luminescent sheet including: an optical sheet having a plurality of protrusions and depressions on its lower surface; a conductive layer disposed on the upper surface of the optical sheet; a color conversion luminescent layer deposited on the upper surface of the conductive layer and comprising a mixture of nanofibers and nanobeads having a binder resin and a color conversion luminescent material; and a protective layer on the upper surface of the color conversion luminescent layer, the protective layer having a stacked structure including an organic polymer protective layer and an inorganic thin protective layer.

Owner:KOREA INST OF SCI & TECH

Graphic image fusion

InactiveUS20070079928A1Quality improvementSatisfactory abrasionLamination ancillary operationsPaper/cardboard articlesGraphicsThermoplastic

An in-mold and in-line decorating method is disclosed which, using a single sheet layer, allows the placement of the highest possible quality graphics into the surface of products made from a variety of moldable thermoplastic, thermoset, and vulcanizable materials using a variety of molding processes. The methods also provide new or improved capabilities for product identification, safety, and serialized tracking.

Owner:STANDARD REGISTER CO

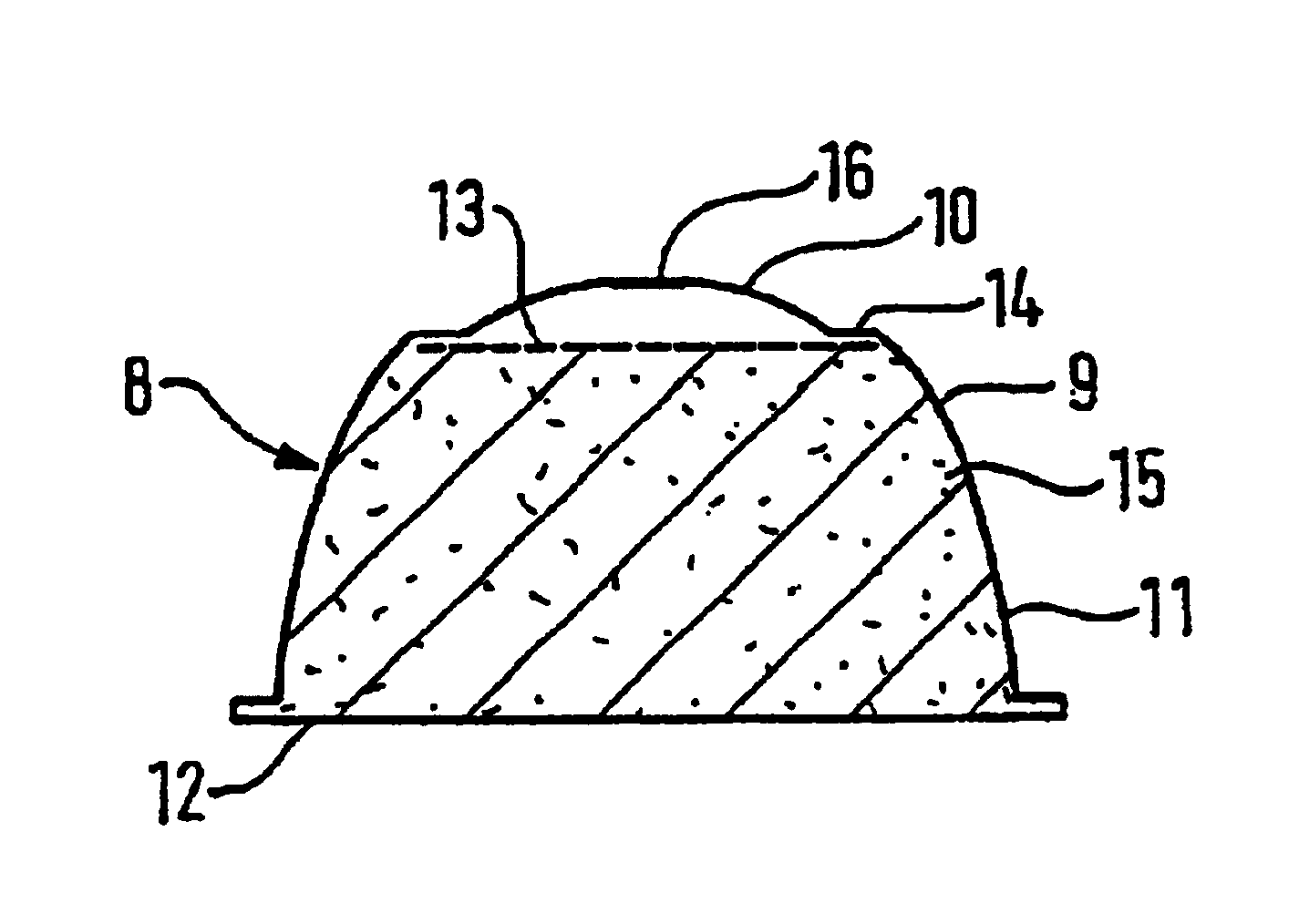

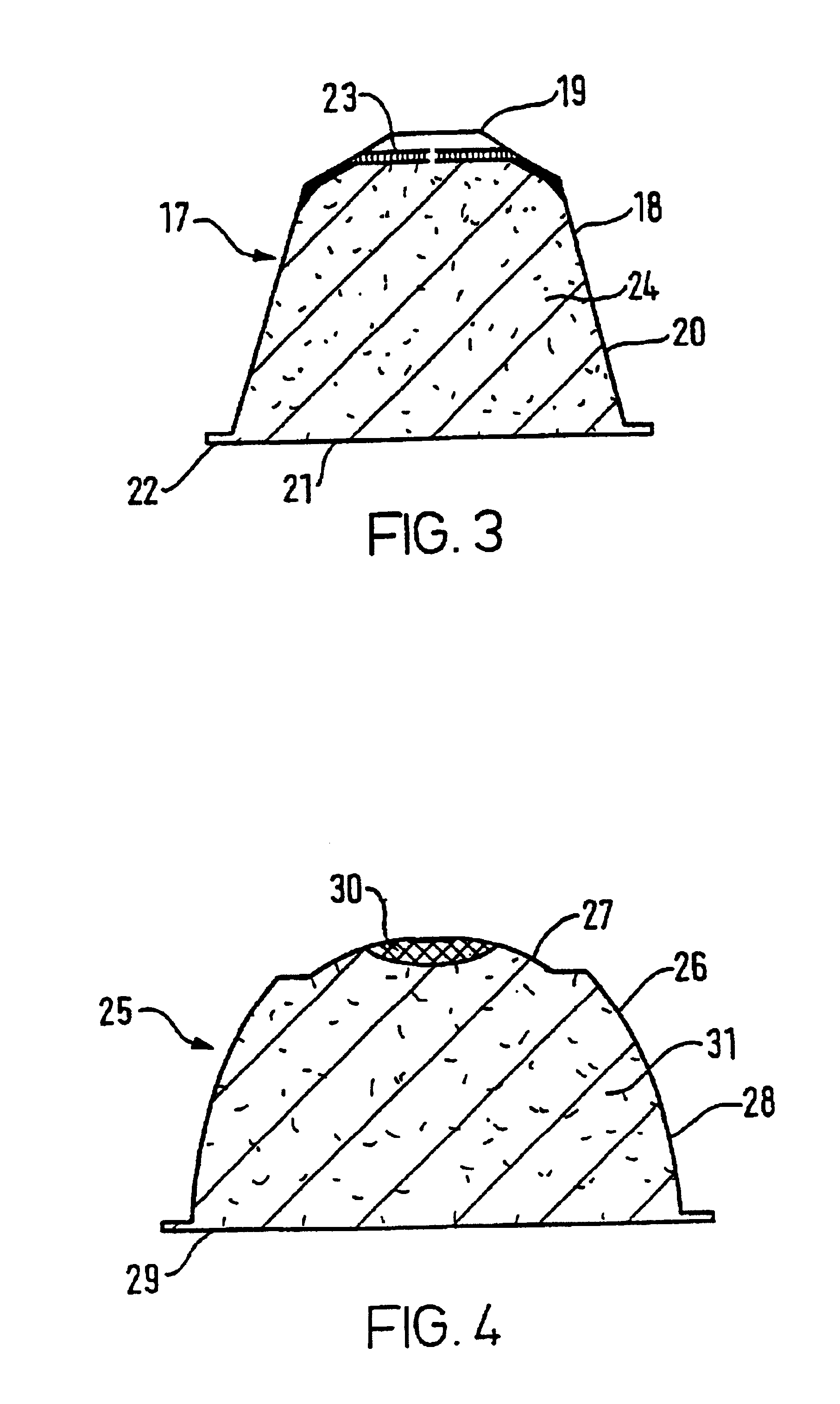

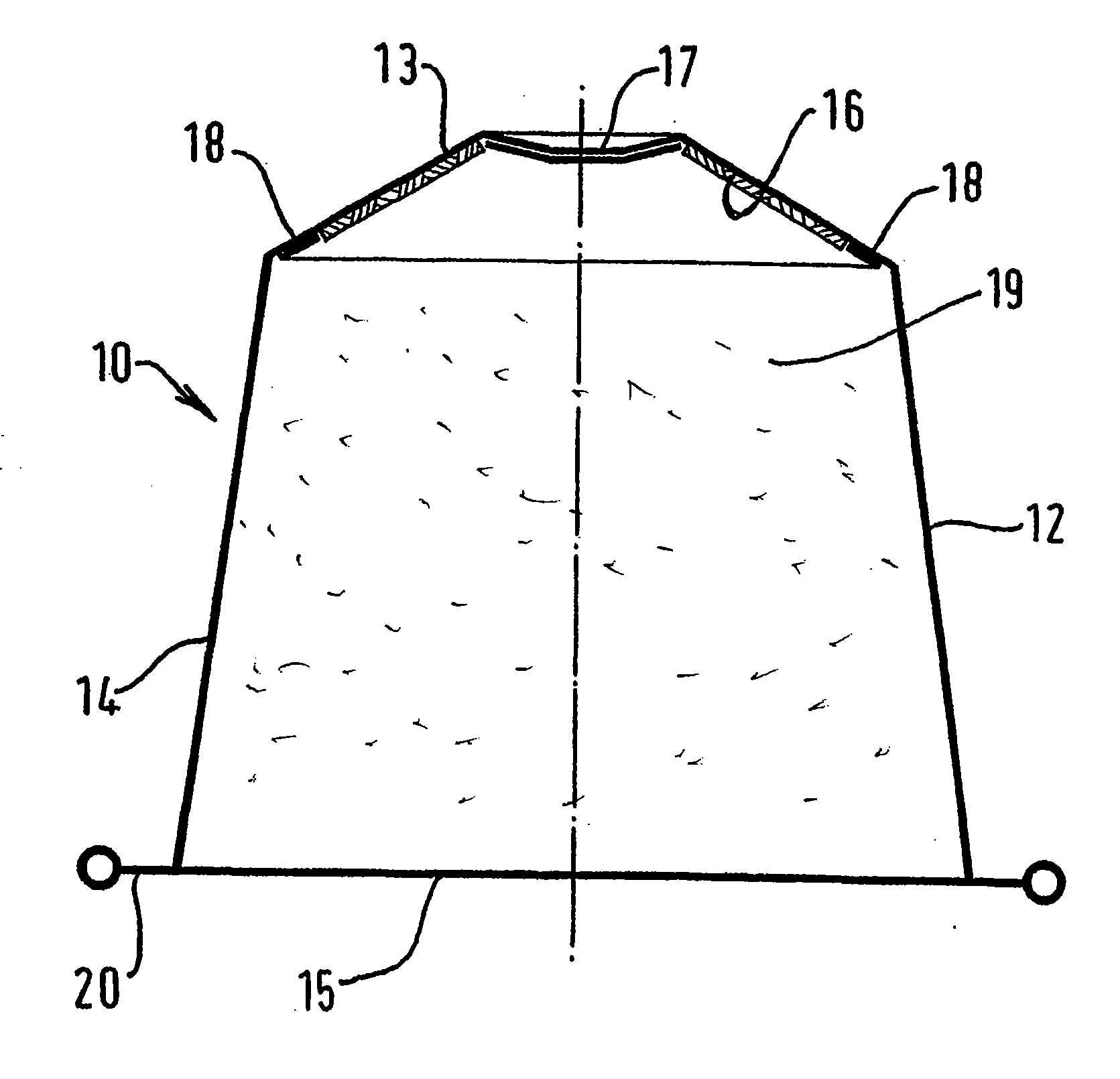

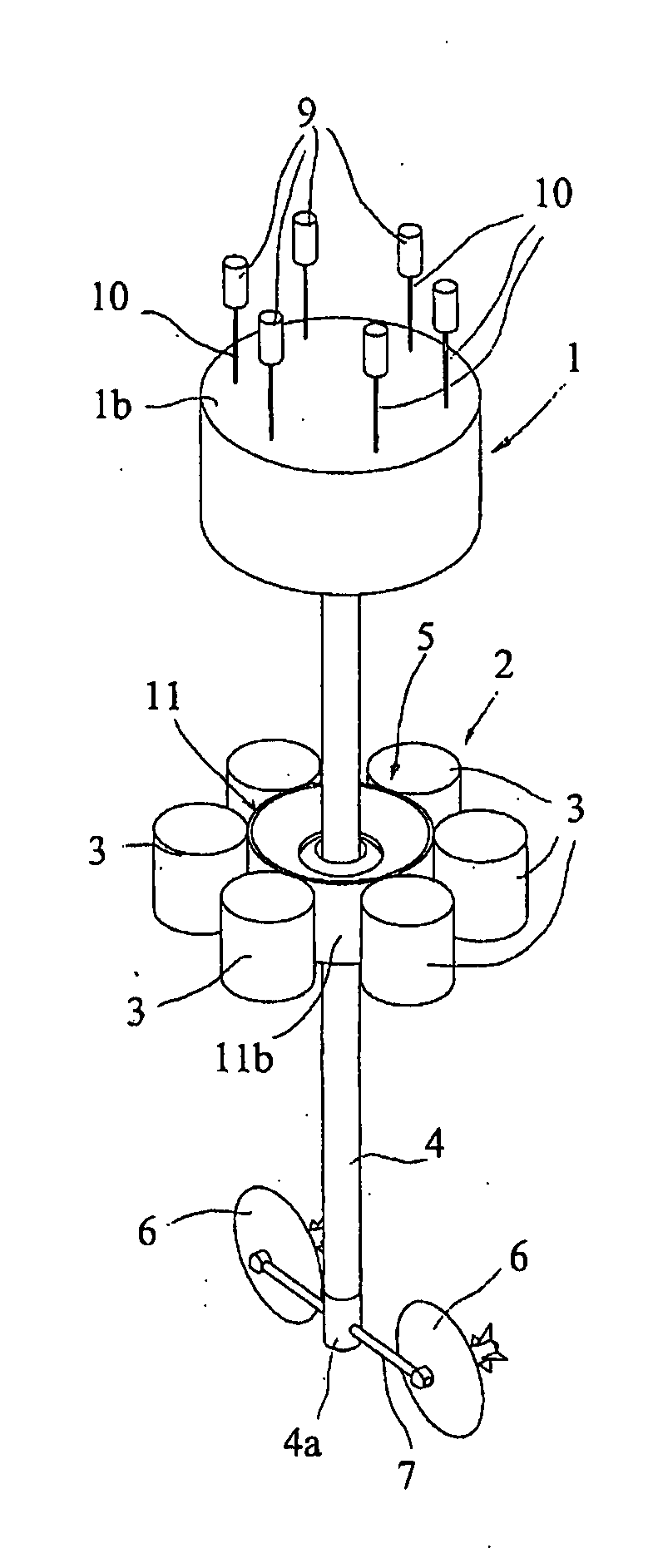

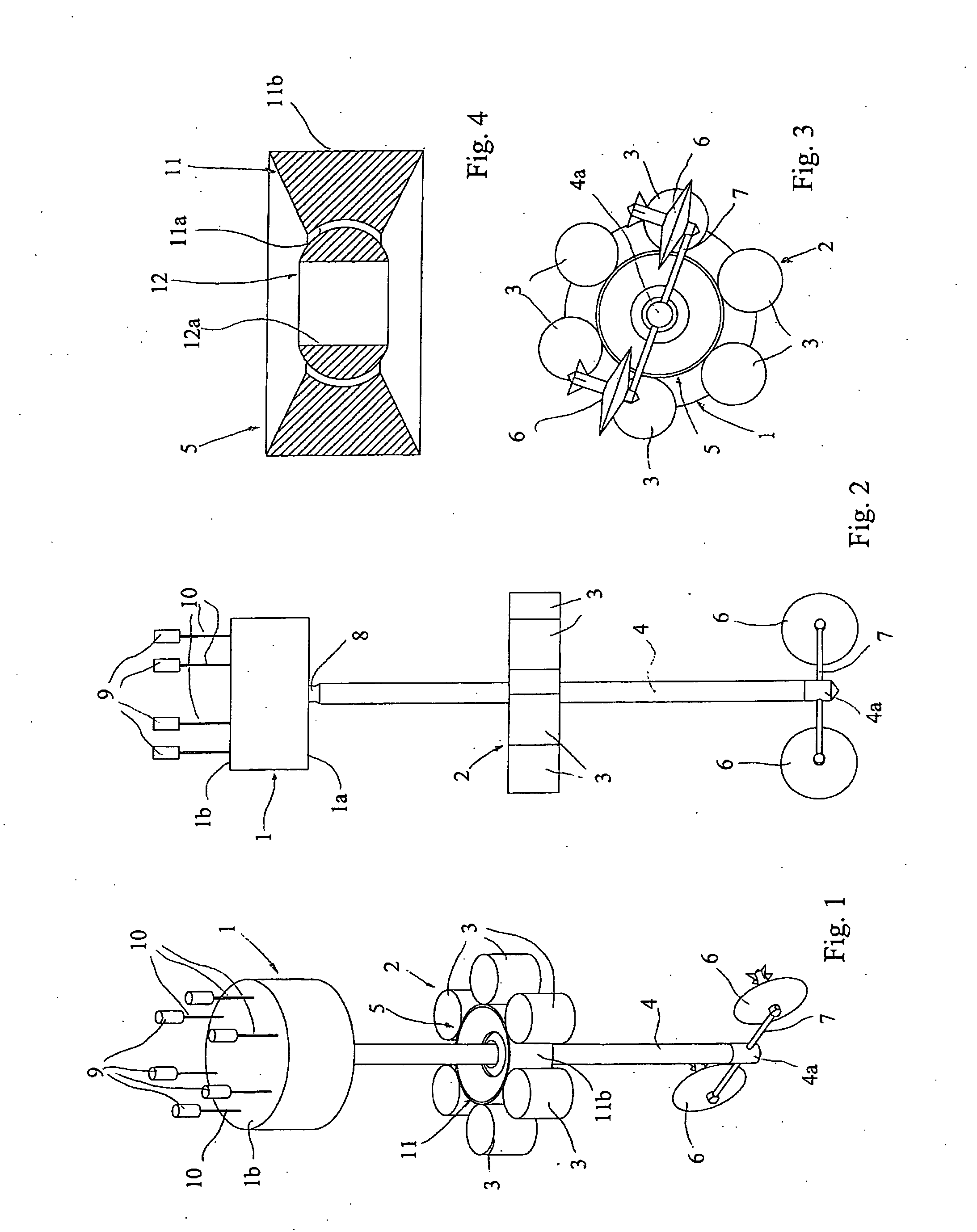

Closed cartridge for preparing a beverage for extraction under pressure

InactiveUS20070068395A1Easy to produceSatisfactory closureDispensing apparatusBeverage vesselsEngineeringStructural engineering

The present invention relates to a closed cartridge (10), for extraction under pressure, comprising a dish (12) with a bottom (13) with a central part and a peripheral part and a side wall having substantially the shape of a frustum of a cone and a circular edge with a diameter greater at the bottom and a cover (15) welded to the periphery of the edge of the dish and the cover is intended to be torn only through the effect of the force of the extraction fluid when extraction starts, the said cartridge comprising, in the dish at the level of the bottom, a means (16) guaranteeing retention of the solid substance when it is opened, in which the means guaranteeing retention of solid substance is a sheet of fabric sealed in the bottom of the dish in two zones, on the one hand in the central part (17) and on the other hand in the peripheral part (18) of the said bottom (13).

Owner:SOC DES PROD NESTLE SA

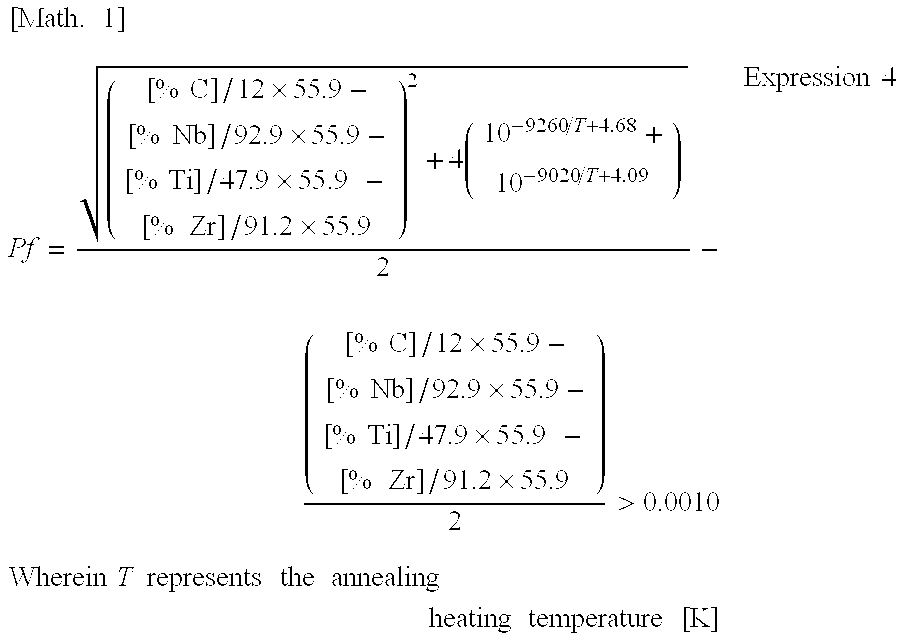

Cold-rolled steel sheet

InactiveUS20120009434A1Improves stretch flangeabilitySatisfactory resistanceSemiconductor/solid-state device detailsExtrusion containersFlangeFormability

Disclosed is a high-strength cold-rolled steel sheet which has improved stretch-flange formability while keeping excellent hydrogen embrittlement resistance. The cold-rolled steel sheet comprises 0.03 to 0.30% by mass of C, 3.0% by mass or less (including 0% by mass) of Si, more than 0.1% by mass and not more than 2.8% by mass of Mn, 0.1% by mass or less of P, 0.005% by mass or less of S, 0.01% by mass or less of N, and 0.01 to 0.50% by mass of Al. The cold-rolled steel sheet additionally comprises V in an amount of 0.001 to 1.00% by mass or one or more elements selected from Nb, Ti and Zr in the total amount of 0.01% by mass or more, with the remainder being made up by iron and unavoidable impurities, wherein the contents of one or more elements selected from Nb, Ti and Zr fulfils the requirement represented by the following formula: [% C]−[% Nb] / 92.9×12−[% Ti] / 47.9×12−[% Zr] / 91.2×12>0.03. In the cold-rolled steel sheet, the area ratio of tempered martensite is 50% or more (including 100%), and ferrite makes up the remainder. In the cold-rolled steel sheet, the distribution of precipitates in the tempered martensite is as follows: the number of precipitates each having a circle-equivalent diameter of 1 to 10 nm is 20 particles or more per 1 μm2 of the tempered martensite and the number of precipitates each containing V or at least one element selected from Nb, Ti and Zr and each having a circle-equivalent diameter of 20 nm or more is 10 particles or less per 1 μm2 of the tempered martensite.

Owner:KOBE STEEL LTD

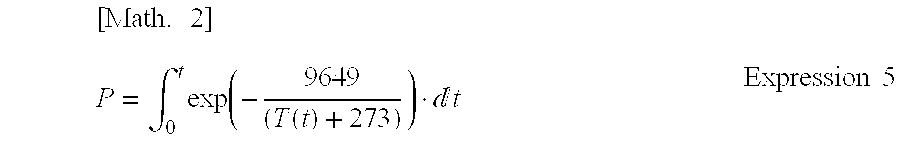

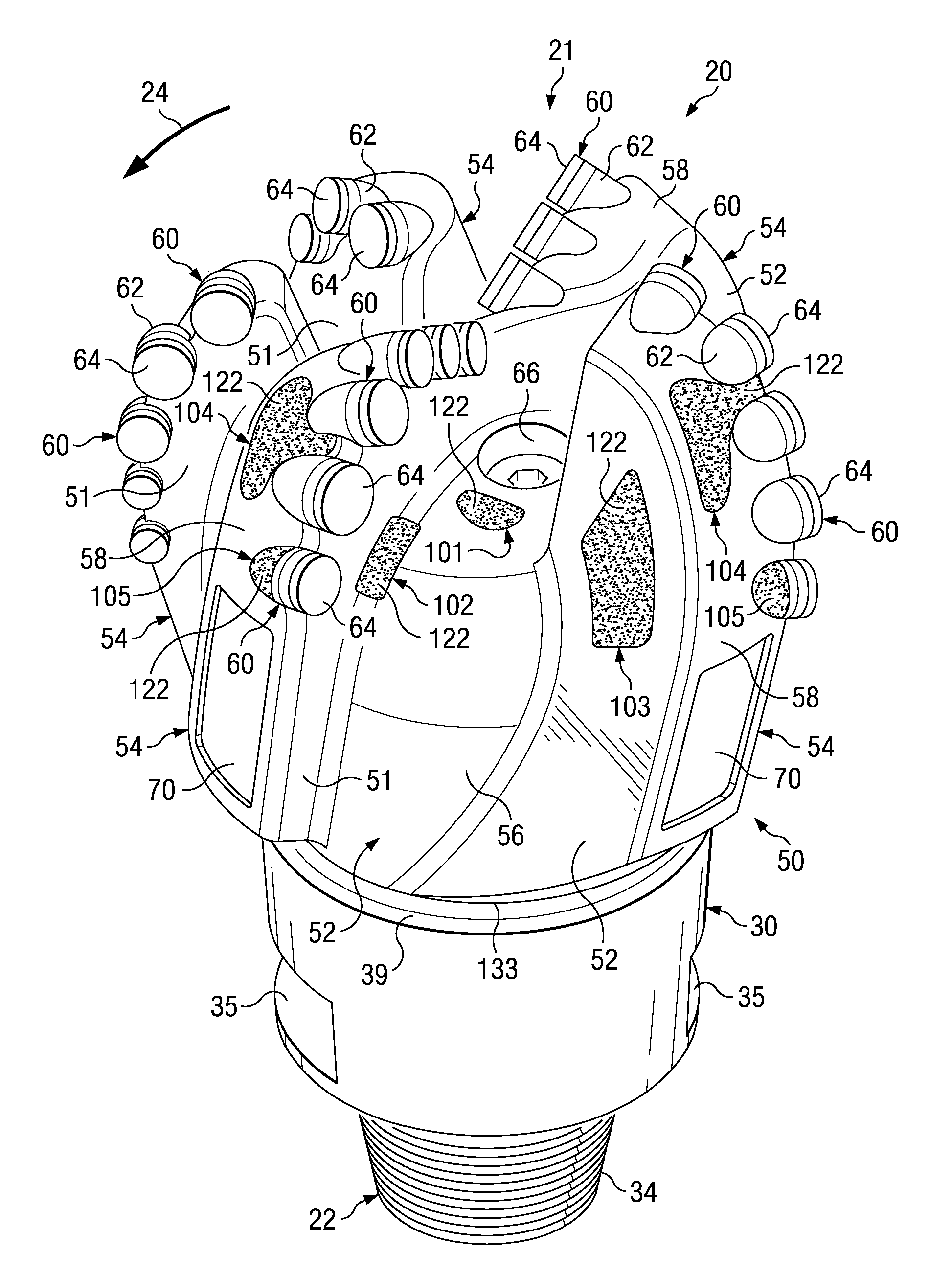

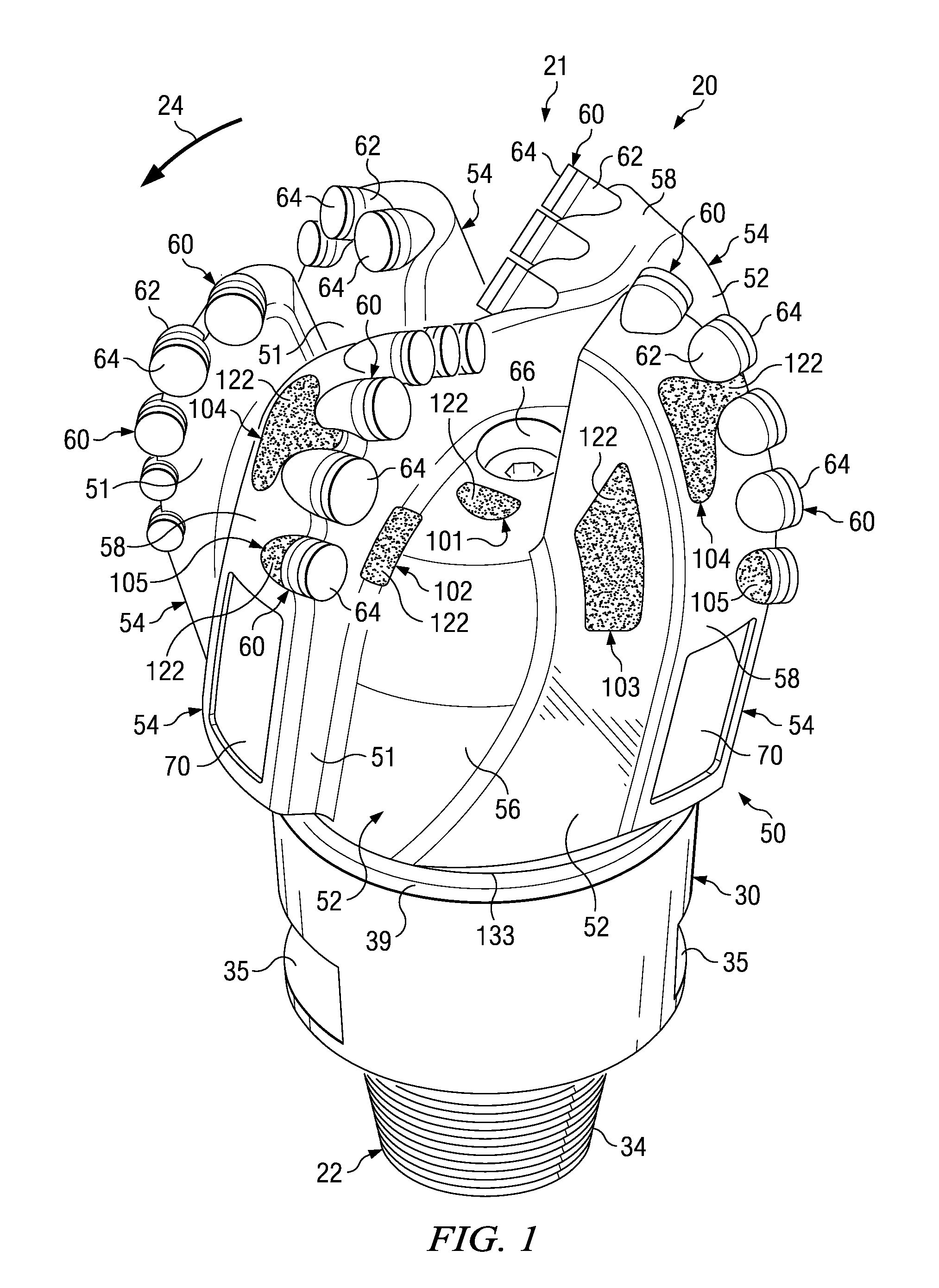

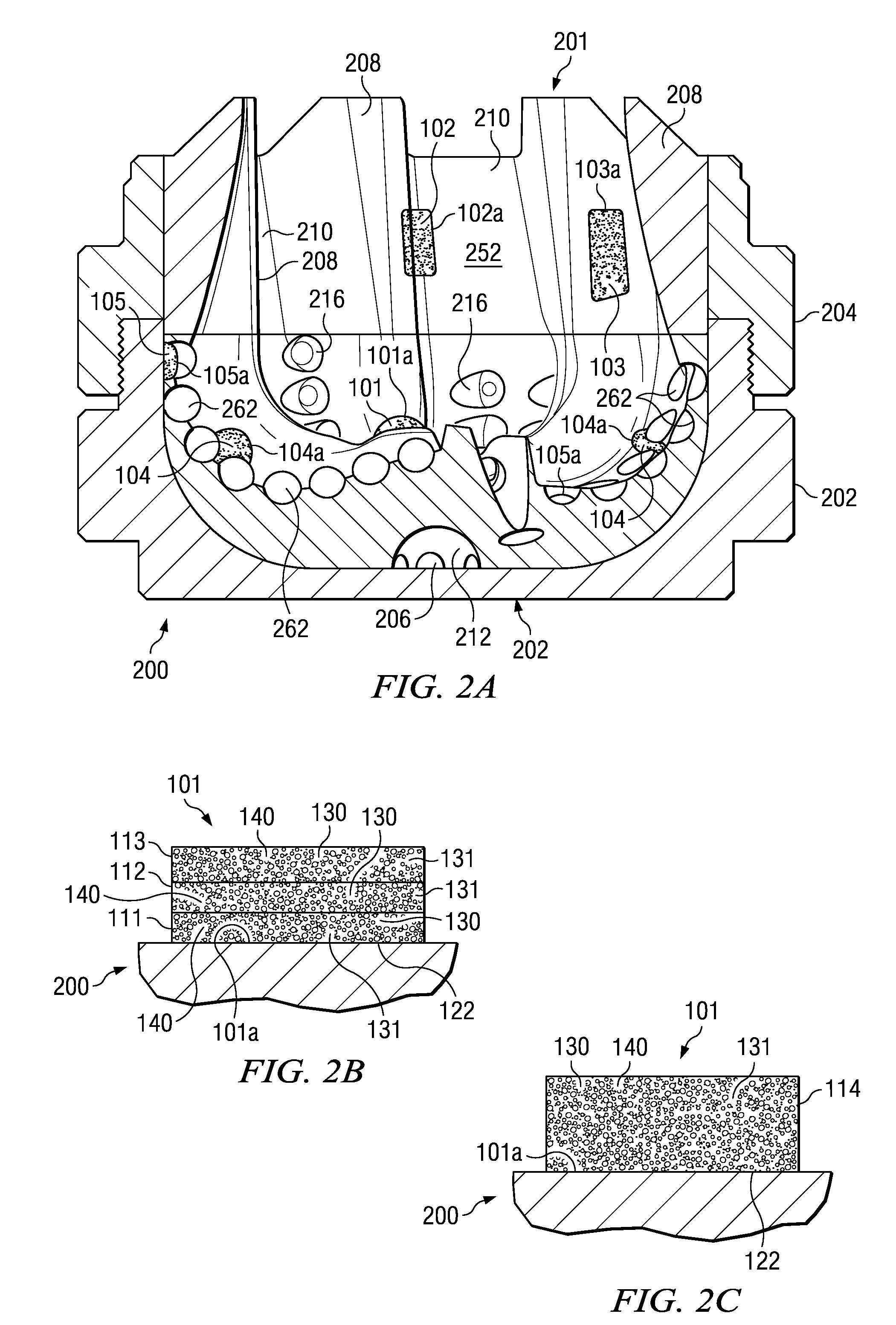

Matrix Drill Bit with Dual Surface Compositions and Methods of Manufacture

InactiveUS20100193254A1Increase contentIncrease in sizePigmenting treatmentDrill bitsEngineeringDrill bit

Matrix drill bits and other downhole tools may be formed with one or more layers of hard materials disposed on exterior portions thereof. Exterior portions of used rotary drill bits or other downhole tools may be measured using three dimensional (3D) scanning techniques or other techniques to determine specific locations of undesired abrasion, erosion and / or wear. During the design of a new rotary drill bit or other downhole tool, computational flow analysis techniques may be used to determine potential locations for excessive erosions, abrasion, wear, impact and / or fatigue on exterior portions of the rotary drill bit or other downhole tools. One or more layers of hard material may be disposed at such locations on exterior portions of matrix bit bodies and other matrix bodies based on analyzing exterior portions of used downhole tools and / or computational flow analysis.

Owner:HALLIBURTON ENERGY SERVICES INC

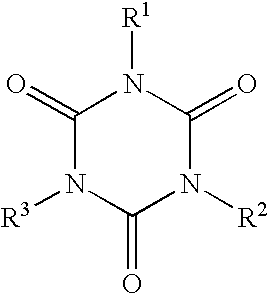

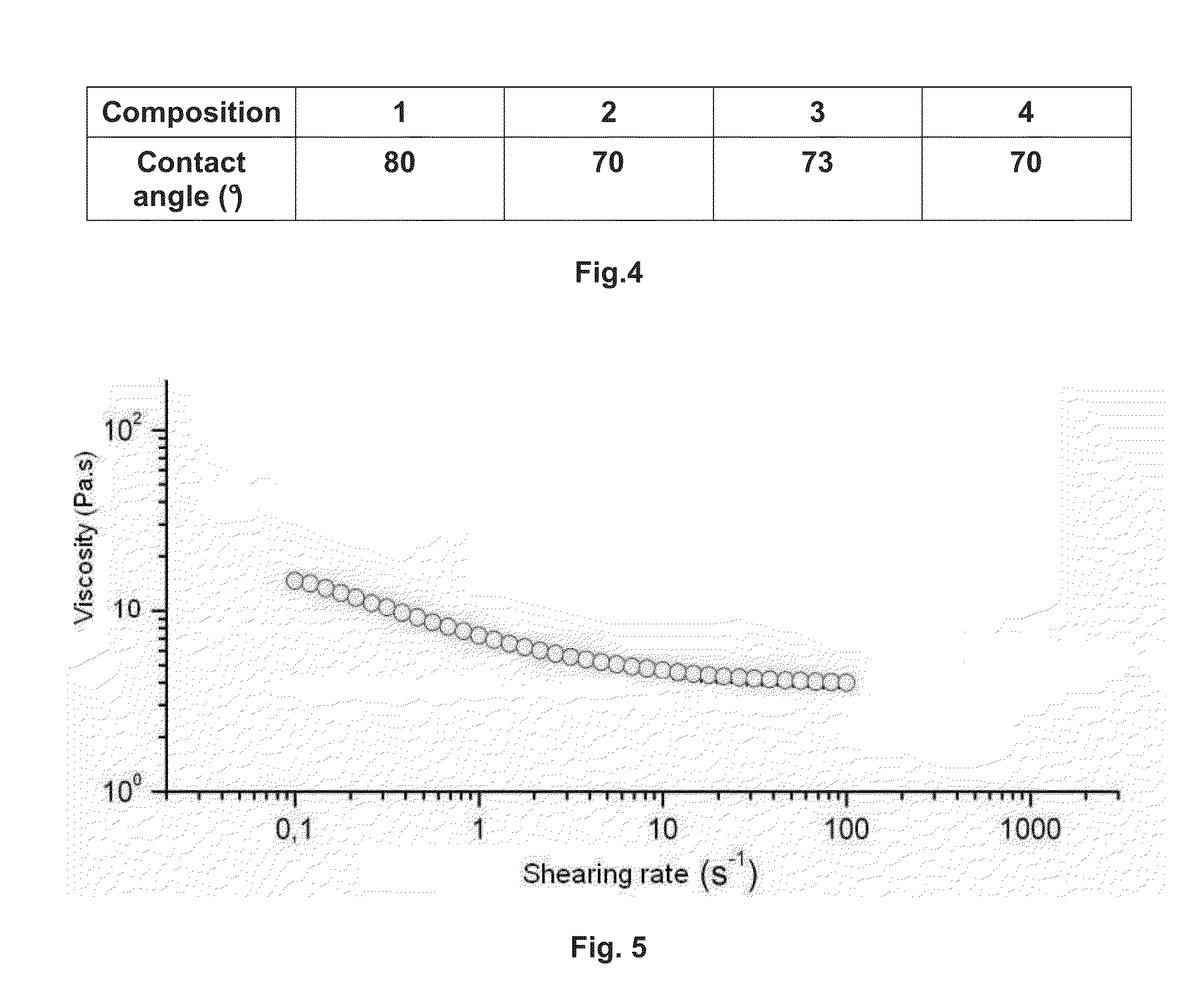

Adhesive for rubber compositions, process for its preparation and articles comprising this adhesive

InactiveUS20020091222A1Low viscosityProvides thermal stabilityPolyureas/polyurethane adhesivesSynthetic resin layered productsPolyesterCross-link

The present invention relates to an adhesive usable at ambient temperature to bond together two cross-linked rubber compositions, to a process for preparing the adhesive, to a tread of a tire cover and to such a cover comprising this adhesive, and to an article comprising two parts bonded together by means of this adhesive. An adhesive based on a copolymer comprising urea or urethane and isocyanurate groups wherein the copolymer is a reaction product of: (a) a polyisocyanate comprising isocyanurate groups, the polyisocyanate having a functionality equal to or greater than three, (b) a functional polymer comprising an amine or alcohol group at each of its chain ends, the functional polymer being selected from the group consisting of polyether diamines, polyether diols, polyester diols and (ester-ether) diol copolymers, and (c) at least one trimerization catalyst capable of forming isocyanurate groups from isocyanate groups, wherein the molar ratio of isocyate groups to amine is between 1.5 and 2.2, and wherein the adhesive is usable at ambient temperature to bond together two cross-linked rubber compositions.

Owner:MICHELIN RECH & TECH SA

Ink-jet recording ink, ink-jet recording ink set, recording method, print, and ink-jet recording apparatus

InactiveUS7307109B2Excellent long-term storage stabilityHigh print densityInksPrintingAlcoholGlycol ethers

An ink jet recording ink (IJ ink) containing a colorant of a pigment and / or dye enveloped in a polymer, and water, and containing at least one compound from the group of acetylene glycol surfactants and acetylene alcohol surfactants, and another compound from the group of glycol ethers and 1,2-alkylene glycols; an IJ ink set including a plurality of the inks; a recording method of using the ink and / or the ink set; recorded matter printed according to the recording method; and an ink jet recording apparatus having an electrostrictive unit mounted thereon and designed so as to be capable of ejecting the ink.

Owner:SEIKO EPSON CORP

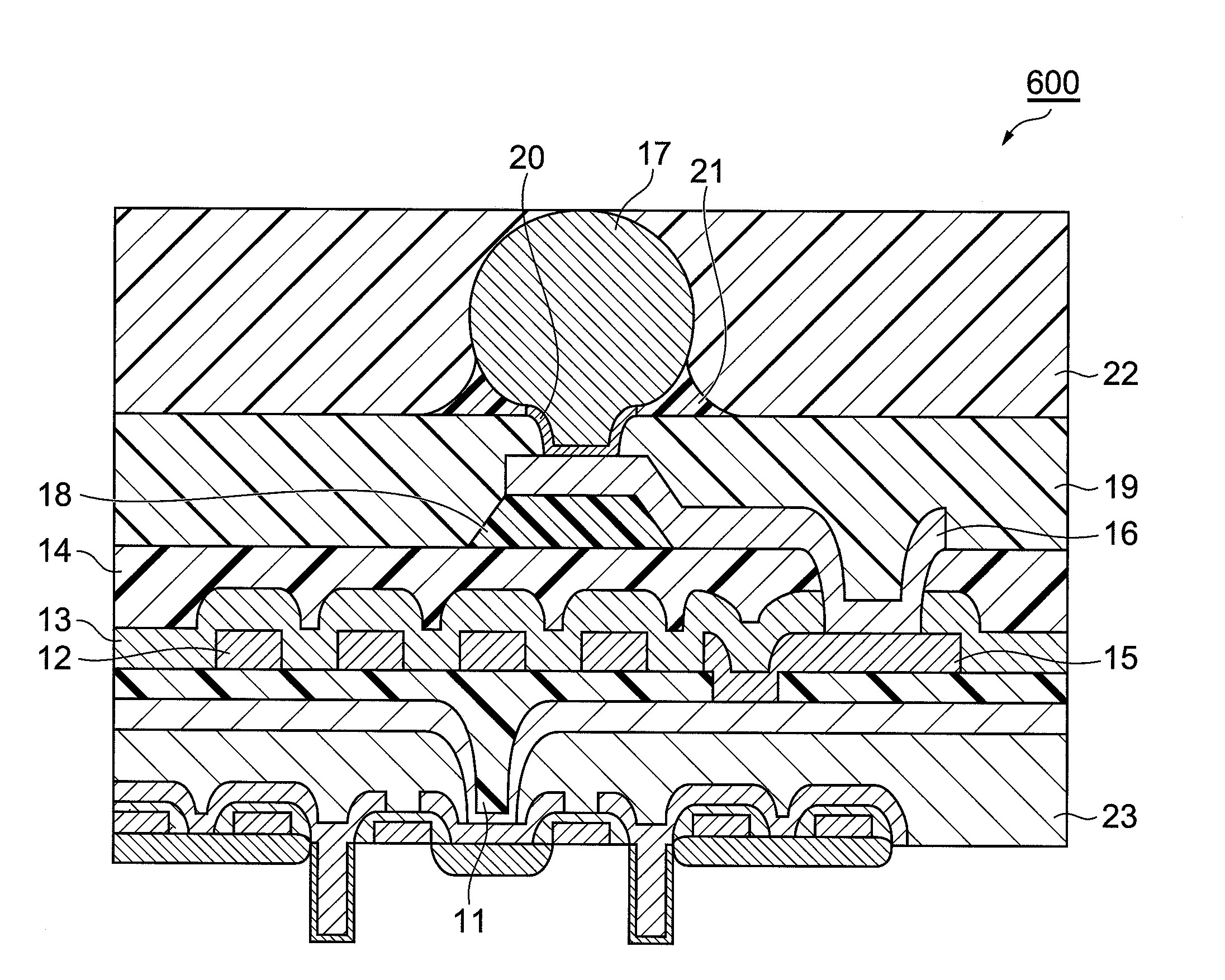

Pressure sensitive adhesive composition, product using the same, and display using the product

InactiveUS20090068459A1Excels in adhesivenessExcels in coatabilityLayered productsEster polymer adhesivesPolymer scienceAlkoxy group

Disclosed is a pressure-sensitive adhesive composition which contains an acrylic polymer and a crosslinking agent. The acrylic polymer has a weight-average molecular weight of 40×104 to 160×104 and contains at least an alkoxyalkyl acrylate (Component A) and an acrylic monomer having a crosslinkable functional group (Component B). The monomer components constituting the acrylic polymer contain 45 to 99.5 parts by weight of Component A and 0.5 to 4.5 parts by weight of Component B to 100 parts by weight of total monomer components constituting the acrylic polymer, and the monomer components constituting the acrylic polymer contain substantially no carboxyl-containing monomers. This relates to improvements to provide pressure-sensitive adhesive compositions that show excellent coatability, transparency, adhesion (typically low-temperature adhesion), and resistance to blistering / separation and concurrently have anticorrosive properties.

Owner:NITTO DENKO CORP

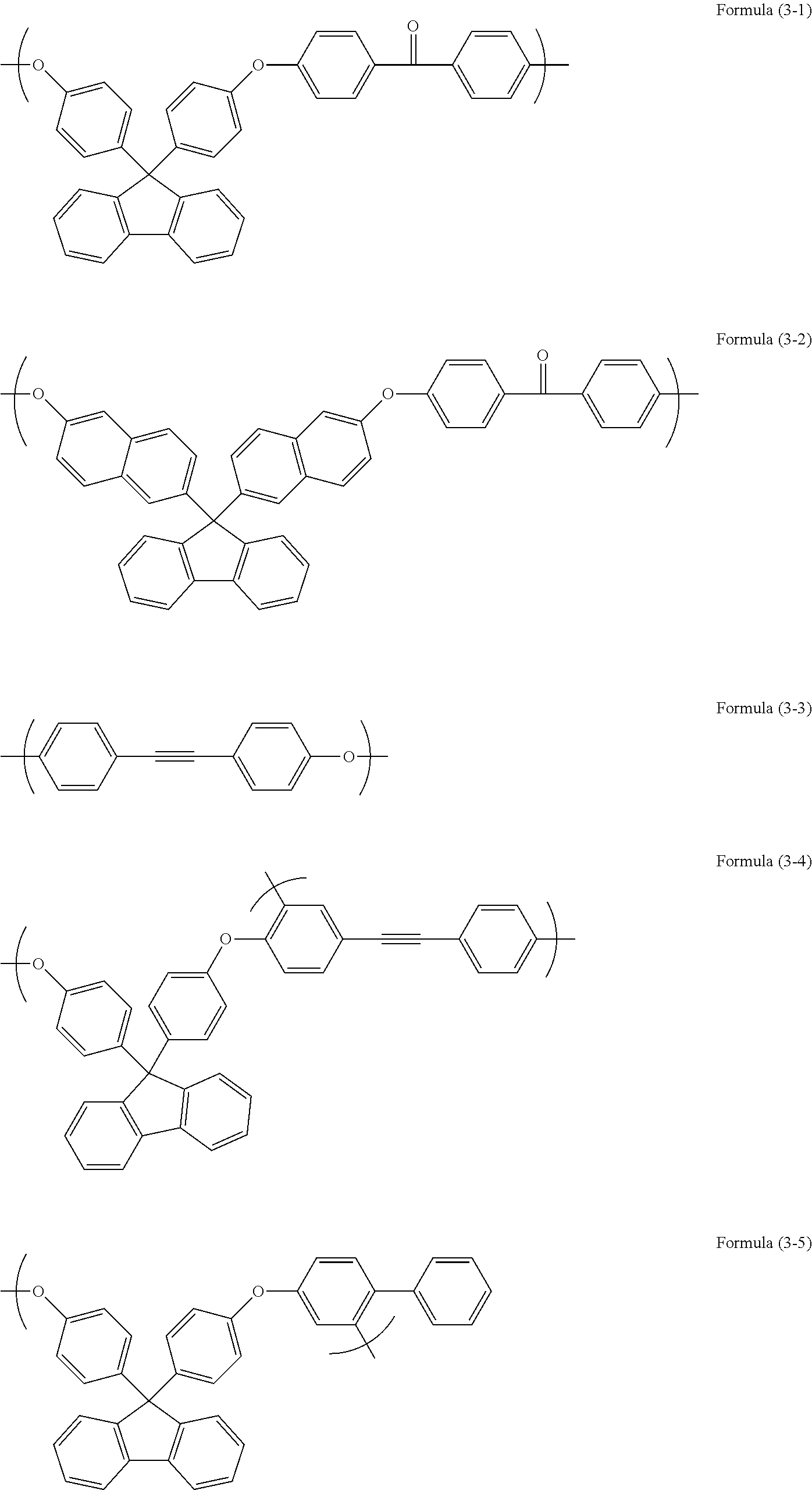

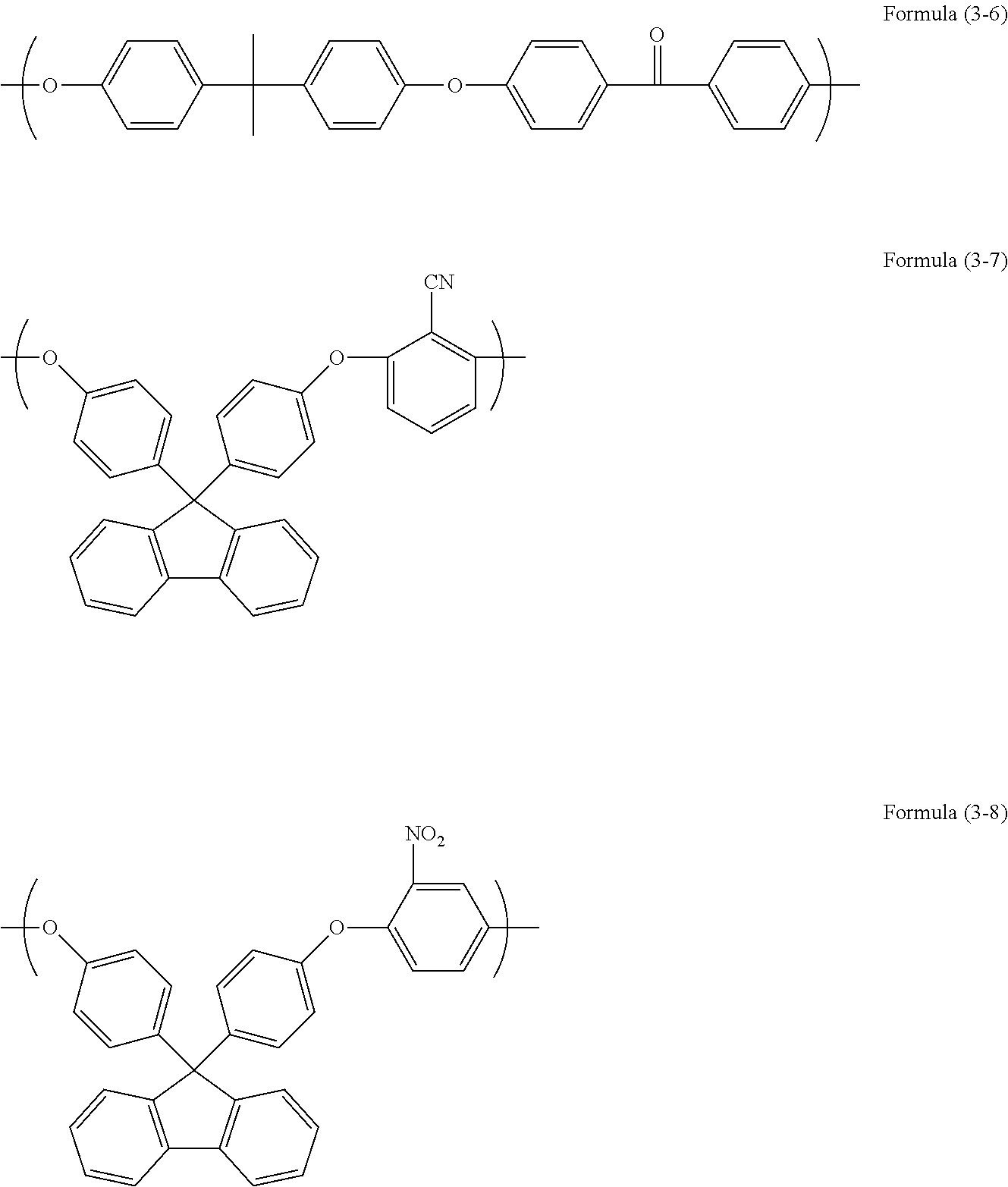

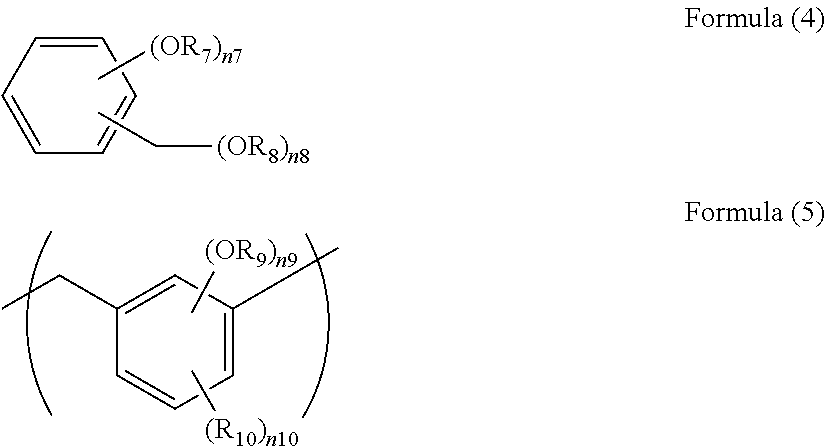

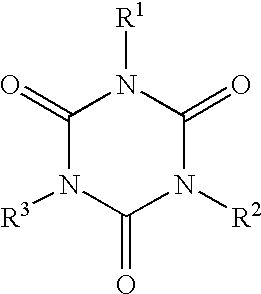

Resist underlayer film forming composition for lithography containing polyether structure-containing resin

InactiveUS20130189533A1Pattern in good shapeInhibition reflexPlastic/resin/waxes insulatorsFibre treatmentPolymer scienceAcyl group

There is provided a resist underlayer film forming composition for forming a resist underlayer film providing heat resistance properties and hardmask characteristics. A resist underlayer film forming composition for lithography, comprising: a polymer containing a unit structure of Formula (1):O—Ar1 Formula (1)(in Formula (1), Ar1 is a C6-50 arylene group or an organic group containing a heterocyclic group), a unit structure of Formula (2):O—Ar2—O—Ar3-T-Ar4 Formula (2)(in Formula (2), Ar2, Ar3, and Ar4 are individually a C6-50 arylene group or an organic group containing a heterocyclic group; and T is a carbonyl group or a sulfonyl group), or a combination of the unit structure of Formula (1) and the unit structure of Formula (2). The organic groups of Ar1 and Ar2 containing arylene group may be organic groups containing a fluorene structure.

Owner:NISSAN CHEM IND LTD

Chemically amplified negative photoresist composition for the formation of thick films, photoresist base material and method of forming bumps using the same

InactiveUS6838229B2High sensitivitySatisfactory plating resistancePhotosensitive materialsRadiation applicationsResistChemical compound

A chemically amplified negative photoresist composition is used for the formation of thick films having a thickness of 20 to 150 μm and includes (A) an alkali-soluble resin, (B) a compound which generates an acid upon irradiation with active light or radiant ray, and (C) a compound which serves as a crosslinking agent in the presence of an acid. The alkali-soluble resin (A) includes (a1) a novolak resin having a weight average molecular weight of from 5000 to 10000, and (a2) a polymer containing at least a hydroxystyrene constitutional unit and having a weight average molecular weight of less than or equal to 5000.

Owner:TOKYO OHKA KOGYO CO LTD

Silicone resin compositions and coated articles

InactiveUS20050158566A1High hardnessImprove toughnessLayered productsCoatingsPolymer sciencePtru catalyst

To a silicone resin obtained through cohydrolytic condensation of 100 pbw of a mixture of 1-50 Si mol % of tetraalkoxysilane, 50-99 Si mol % of trialkoxysilane and 0-10 Si mol % of dialkoxysilane with less than 100 pbw of water, having a Mn of at least 1,500 and containing 30-80 mol % of R1SiO3 / 2 units and 20-70 mol % of R1SiO2 / 2(OX) and R1SiO1 / 2(OX)2 units combined, a curing catalyst and a solvent are added to formulate a silicone resin composition. It is applied and heat cured to a plastic substrate to form a protective coat having a high hardness and improved properties such as mar resistance, crack resistance, adhesion, water resistance, heat resistance and weathering resistance.

Owner:SHIN ETSU CHEM IND CO LTD

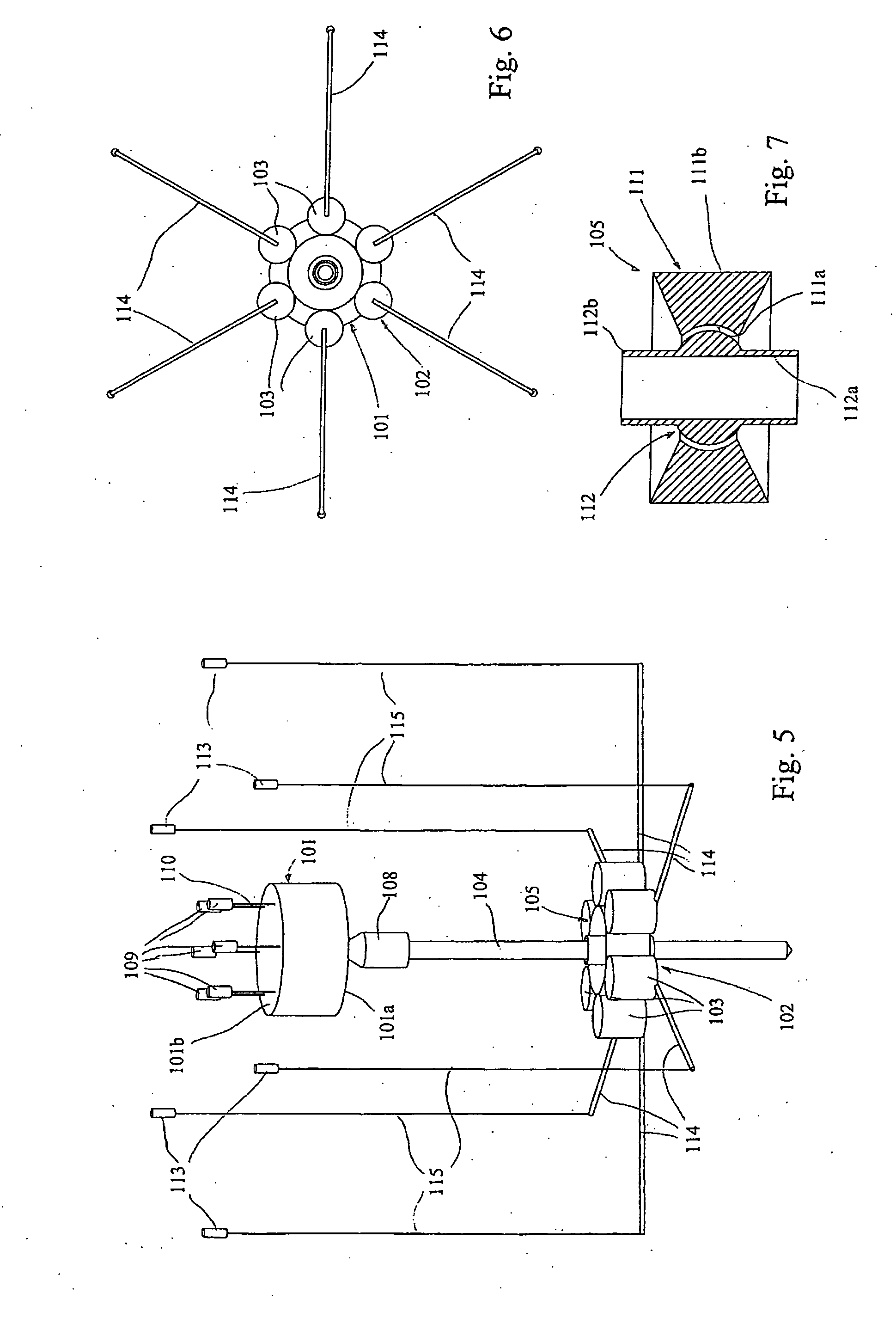

Completely submerged wave energy converter

InactiveUS20100164227A1Satisfactory resistanceImprove efficiencyGas turbine plantsEngine componentsEngineeringWater particle

A wave energy converter apparatus comprising at least two members joined mutually by a connector movable so as to allow mutual displacement of the members in response to waves in water where the apparatus is located. The apparatus also includes an energy converter for converting motion of the connector to electrical energy, and a device for storing and / or transporting elsewhere the energy produced. Preferably, the members are non-floating and completely submerged, thereby causing the apparatus, as a whole, to be neutrally buoyant. A member is additionally provided for maintaining each of the submerged members substantially at rest relative to the surrounding water with which they are in contact, such that the members move under wave action substantially in the same manner as an undisturbed water particle located in the same region, the at least two submerged members being spaced mutually by the connector so as to assume respective positions affected differently by the wave-induced water motion.

Owner:40SOUTH ENERGY

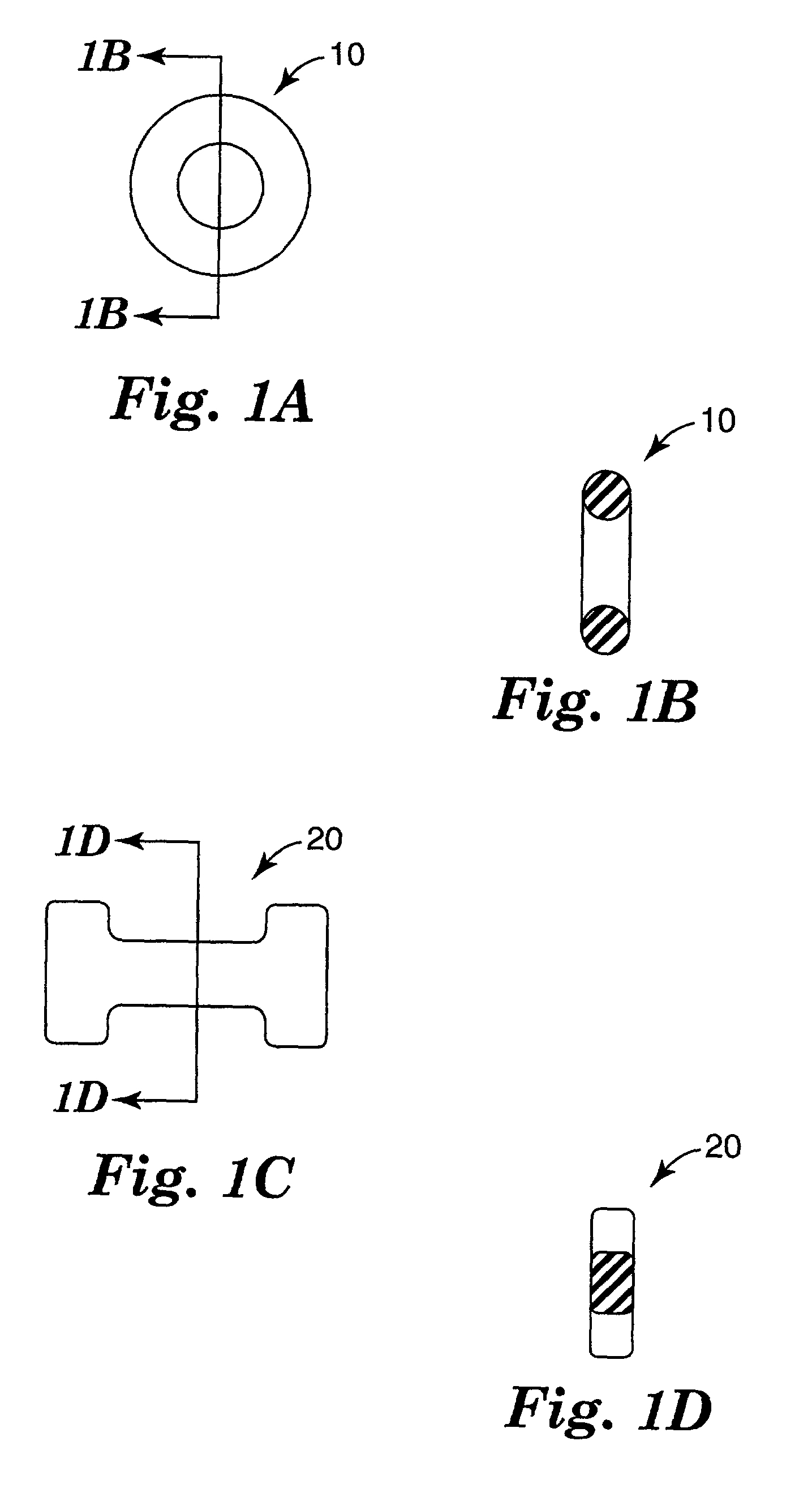

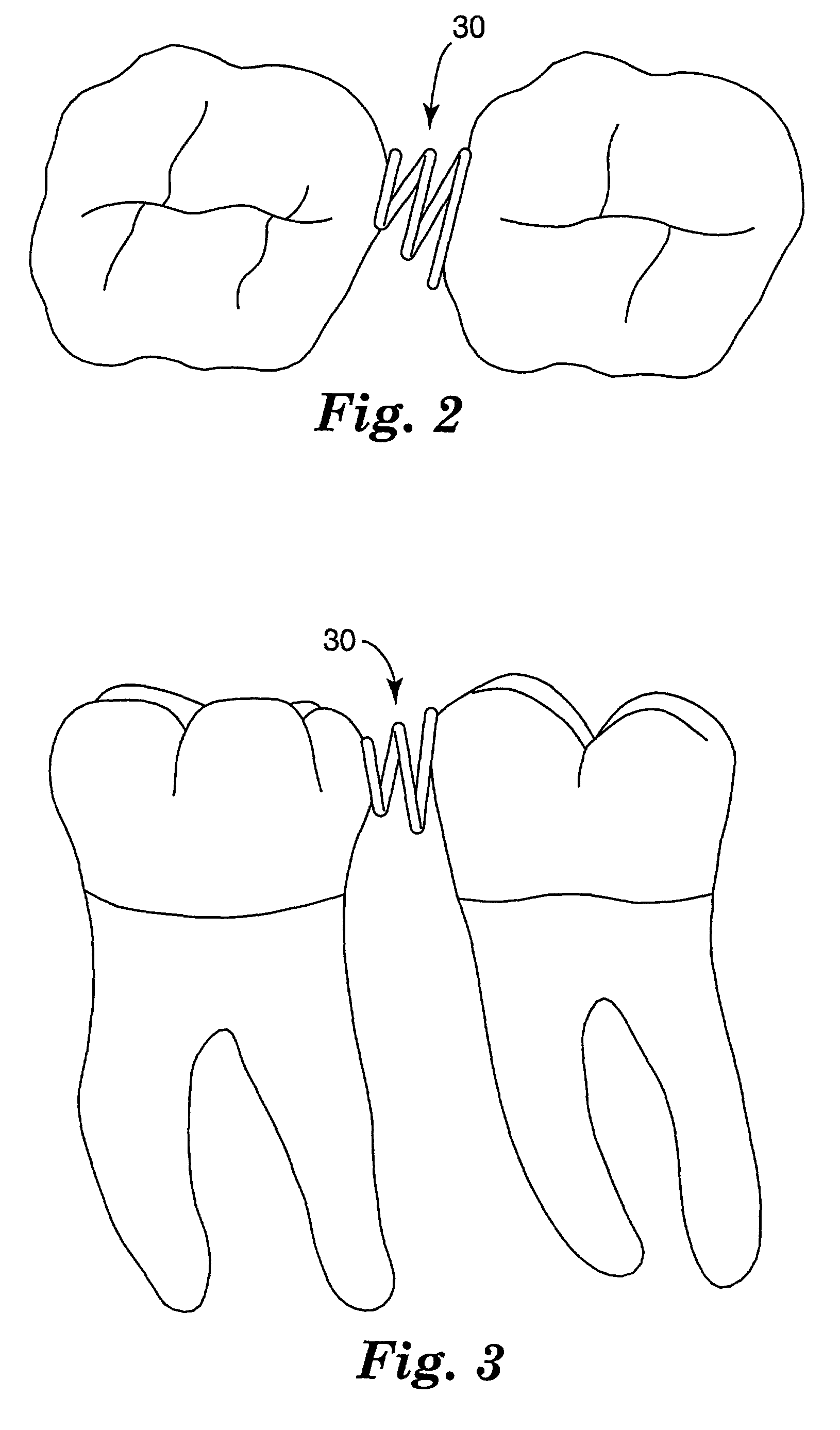

Orthodontic separators

InactiveUS6988887B2Satisfactory resistance to force degradationEasy to insertArch wiresDental toolsOrthodonticsOral cavity

An orthodontic separator, dimensioned such that it can be inserted between adjacent teeth. The separator is characterized in that it exhibits an increase in compressive force after insertion between adjacent teeth in the oral environment. The separator, after insertion, exerts sufficient force on the adjacent teeth to push the teeth apart.

Owner:3M INNOVATIVE PROPERTIES CO

Piezoelectric material, piezoelectric element, and electronic equipment

ActiveUS20150368162A1High constantSatisfactory insulation propertyTelevision system detailsInking apparatusRare-earth elementComposite material

There is provided a lead- and potassium-free piezoelectric material having a high piezoelectric constant and a satisfactory insulation property and a piezoelectric element that includes the piezoelectric material. The piezoelectric material contains a perovskite-type metal oxide having the general formula (1): (NaxBa1-y)(NbyTi1-y)O3 (wherein x satisfies 0.80≦x≦0.95, and y satisfies 0.85≦y≦0.95); and at least one rare-earth element selected from La, Pr, Nd, Pm, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm, Yb, and Lu, wherein the rare-earth element content is more than 0 mol % and 5 mol % or less of the amount of perovskite-type metal oxide. The piezoelectric element includes the piezoelectric material.

Owner:CANON KK

Thermoplastic acrylic resin composition

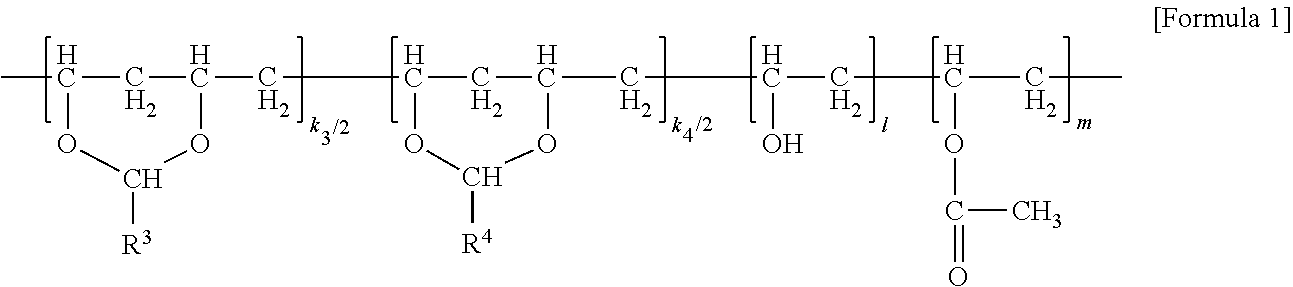

InactiveUS20110112247A1Satisfactory impact resistanceSatisfactory toughnessThin material handlingAcrylic resinPolyvinyl alcohol

Provided is a thermoplastic acrylic resin composition comprising a methacrylic resin (A) and a polyvinyl acetal resin (B) obtained by acetalizing a polyvinyl alcohol resin with an aldehyde having 4 or more carbon atoms and an aldehyde having 3 or less carbon atoms in which the total amount of the vinyl alcohol units acetalized with the aldehyde having 4 or more carbon atoms and the aldehyde having 3 or less carbon atoms is 65 to 85 mol % of all repeating units, and the molar ratio of the vinyl alcohol unit acetalized with the aldehyde having 4 or more carbon atoms to the vinyl alcohol unit acetalized with the aldehyde having 3 or less carbon atoms is from 90 / 10 to 0 / 100. Furthermore, provided are an article molded from the thermoplastic acrylic resin composition and a method of producing the thermoplastic acrylic resin composition comprising the steps of mixing a methacrylic resin (A) and a polyvinyl acetal resin (B), increasing the resin temperature to 160° C. or more, and then decreasing the resin temperature to 120° C. or less.

Owner:KURARAY CO LTD

Positive-type photosensitive resin composition, method for producing resist pattern, semiconductor device, and electronic device

ActiveUS20110254178A1High sensitivityHigh resolutionPhotosensitive materialsSemiconductor/solid-state device detailsAcrylic resinPositive type

The positive tone photosensitive composition of the invention comprises an alkali-soluble resin having a phenolic hydroxyl group, a compound producing an acid by light, a thermal crosslinking agent and an acrylic resin. It is possible to provide a positive tone photosensitive composition that can be developed with an aqueous alkali solution, has sufficiently high sensitivity and resolution, and can form a resist pattern with excellent adhesiveness and thermal shock resistance.

Owner:RESONAC CORP

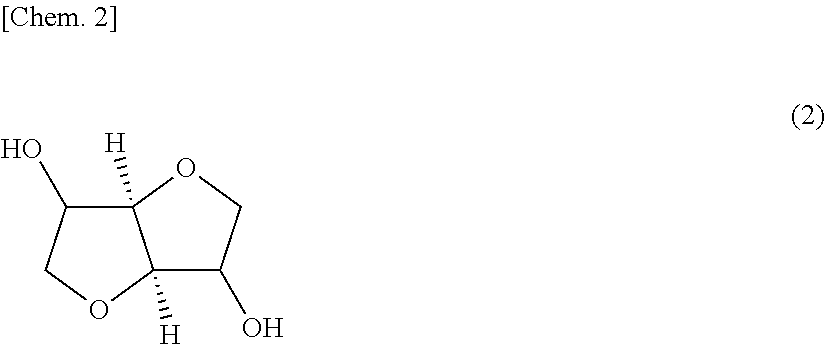

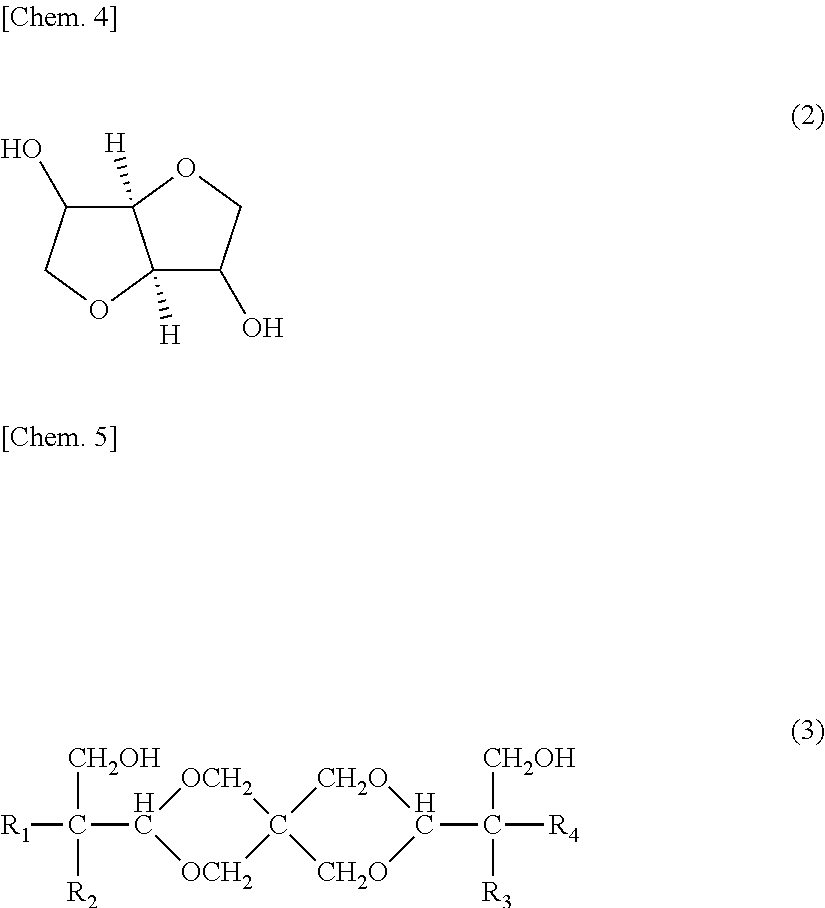

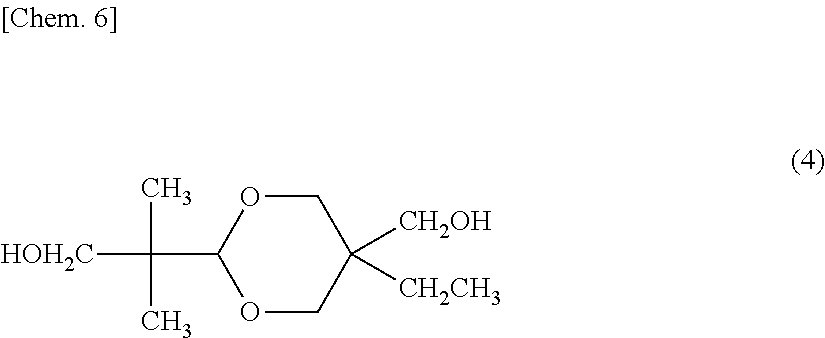

Laminate

InactiveUS20120328855A1Reduce thicknessHigh surface hardnessDecorative surface effectsDuplicating/marking methodsChemical compoundHardness

A laminate excellent in terms of surface hardness, impact resistance, punchability, and yellowing deterioration resistance and suitable for use as display covers and building materials is provided. A laminate characterized by laminating a layer of a polycarbonate resin which contains a structural unit derived from a dihydroxy compound having, as part of the structure thereof, a site represented by the following formula (1) (layer A) to a layer of an aromatic polycarbonate resin (layer B).[Chem. 1]CH2—O (1)(The case where the site represented by the above formula (1) is part of —CH2—O—H is omitted.)

Owner:MITSUBISHI CHEM CORP

Antireflection Film, Production Method Thereof, Polarizing Plate Using the Antireflection Film and Image Display Device Using the Antireflection Film or Polarizing Plate

InactiveUS20080285133A1Improve productivitySatisfactory performanceSynthetic resin layered productsPretreated surfacesRefractive indexSilicon

An antireflection film comprises: a support; and at least one low refractive index layer including a first low refractive index layer, the first low refractive index layer being located most distant from the support, wherein the first low refractive index layer comprises: a resin curable upon irradiation with ionizing radiation; and a compound having a polysiloxane partial structure, and wherein the ratio Si(a) / Si(b) of a photoelectron spectral intensity {Si(a)} of silicon atom on the outermost surface of the first low refractive index layer to a photoelectron spectral intensity {Si(b)} of silicon atom in a deeper position at a depth corresponding to 80% of a thickness of the first low refractive index layer from the outermost surface is 5.0 or more.

Owner:FUJIFILM CORP

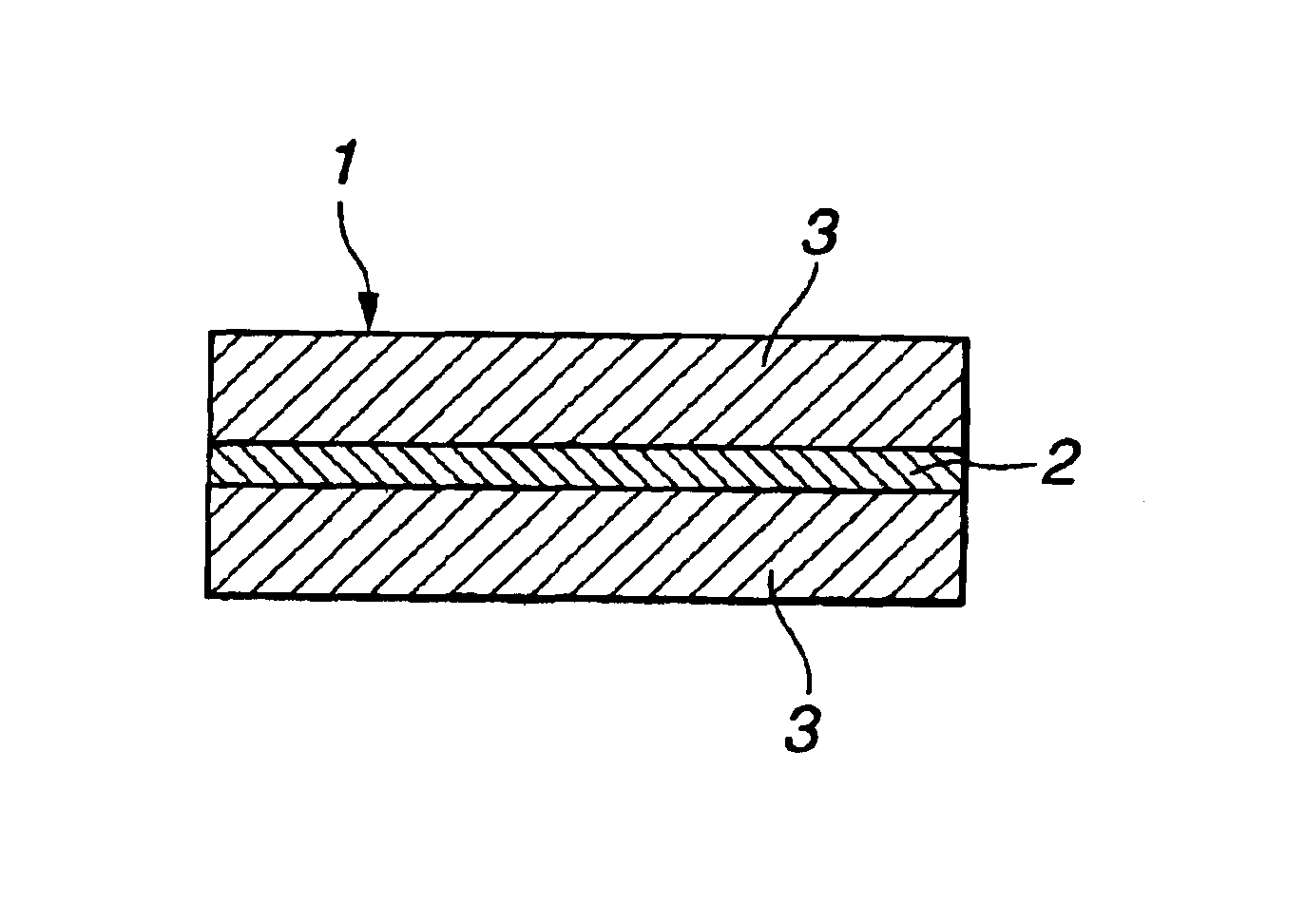

Aluminum alloy clad material

InactiveUS20110027610A1Small thicknessReduce weightWelding/cutting media/materialsCoatingsFilling materialsImpurity

Disclosed is an aluminum alloy clad material which includes a core material; a sacrificial anode material on one surface of the core material; and a filler material on the other surface of the core material and composed of an Al—Si alloy, in which the core material contains 0.3 to 2.0 percent by mass of Mn, 0.15 to 1.6 percent by mass of Si, 0.1 to 1.0 percent by mass of Cu, and 0.1 to 1.0 percent by mass of Mg, with the remainder including Al and inevitable impurities, the sacrificial anode material contains 7.0 to 12.0 percent by mass of Zn, 0.3 to 1.8 percent by mass of Mn, and 0.3 to 1.2 percent by mass of Si, with the remainder including Al and inevitable impurities, and has a thickness of 10 to 30 μm. The sacrificial anode material shows resistance to both local corrosion and general corrosion.

Owner:KOBE STEEL LTD

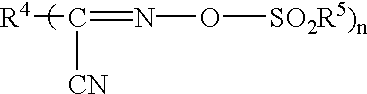

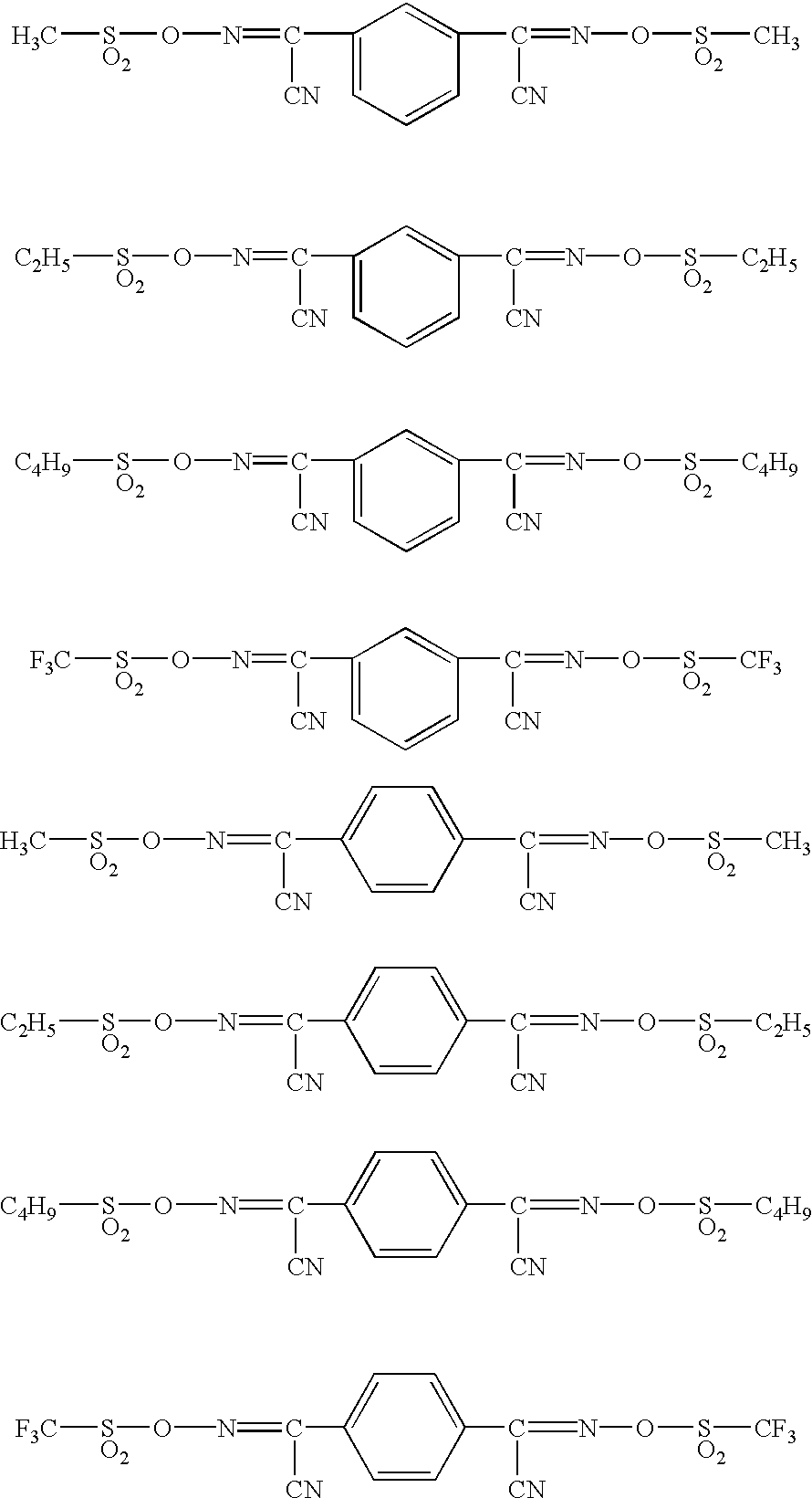

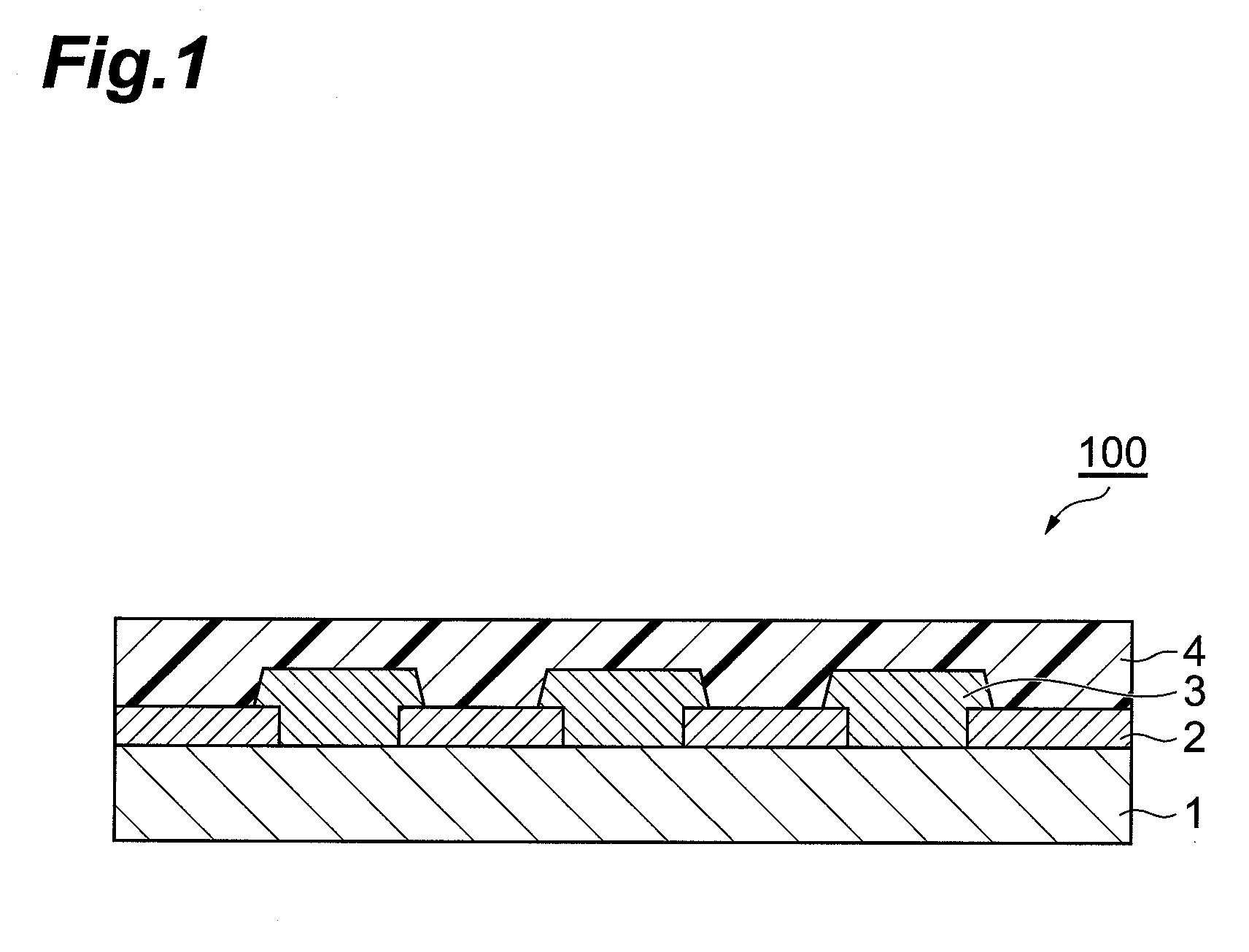

Negative photoresist compositions for the formation of thick films, photoresist films and methods of forming bumps using the same

InactiveUS7063934B2High sensitivitySatisfactory resistanceRadiation applicationsSemiconductor/solid-state device manufacturingResistPlasticizer

Owner:TOKYO OHKA KOGYO CO LTD

Block copolymer composition

ActiveUS20070093601A1Satisfactory in of impact resistanceSatisfactory impact resistanceRecord information storageOptical recording/reproducingPolymer scienceInjection moulding

To provide a block copolymer composition having a good balance in transparency and impact resistance, and particularly having an excellent impact resistance, by making a molded product of injection molding under high sear condition in such a manner as to hardly generate anisotropy. A block copolymer composed of a hard segment block comprising a block made mainly of a vinyl aromatic hydrocarbon and a soft segment block comprising a block made mainly of a conjugated diene, characterized by having a remarkably improved impact resistance without degrading transparency in respect of not only an extrusion-molded product and a blow-molded product but also an injection-molded product, by blending two kinds of block copolymers having a hard segment block of a specific structure.

Owner:DENKA CO LTD

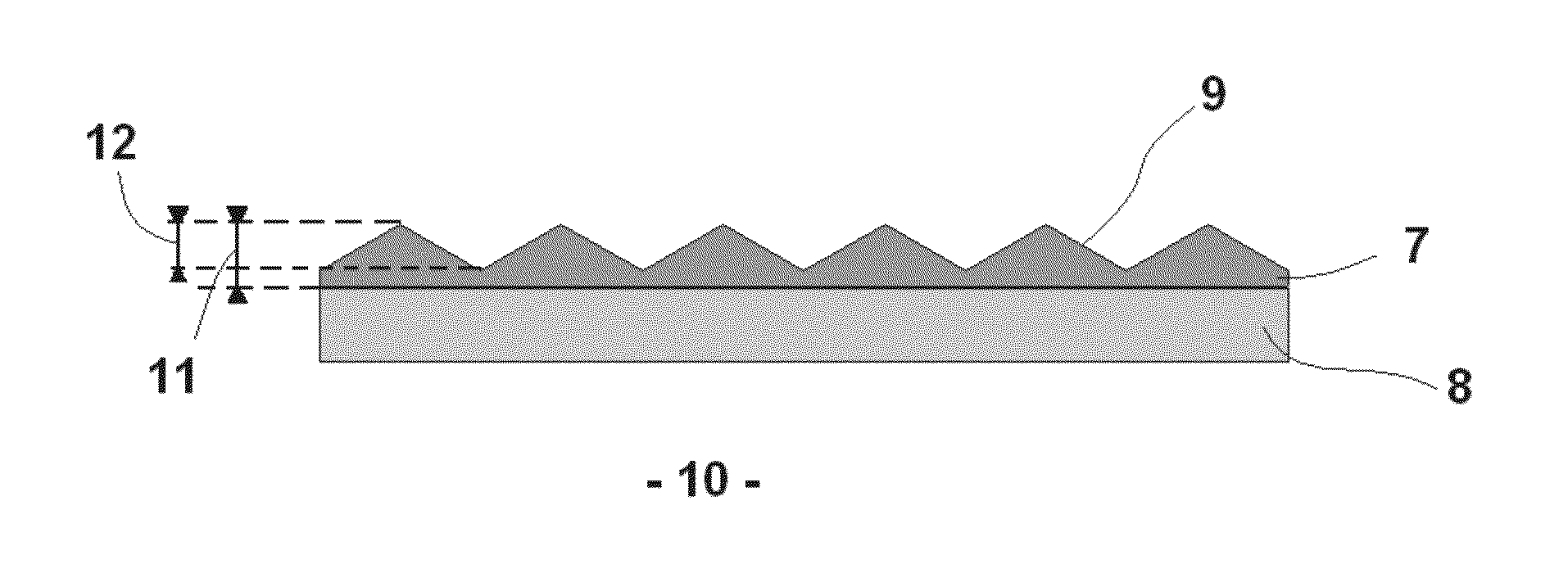

Multifunctional coating for aircraft

ActiveUS20130101800A1Satisfactory resistanceImprove hydrophobicityLayered productsPolyurea/polyurethane coatingsOligomerSilicon dioxide

A method for coating a surface comprises applying a layer of coating composition onto the surface, mechanically forming parallel ribs on the layer, and simultaneously polymerizing the layer with ultraviolet radiations. The coating composition comprises a mass percentage of urethan-acrylate oligomer, with an average molar mass in number between 1000 and 5000 g·mol−1, between 35% and 75%. The coating composition further comprises a mass percentage of a diluting agent, copolymerizable with urethan-acrylate oligomers, between 15% and 60%, and a mass percentage of pyrogenic silica between 0.5% and 5%.

Owner:AIRBUS +1

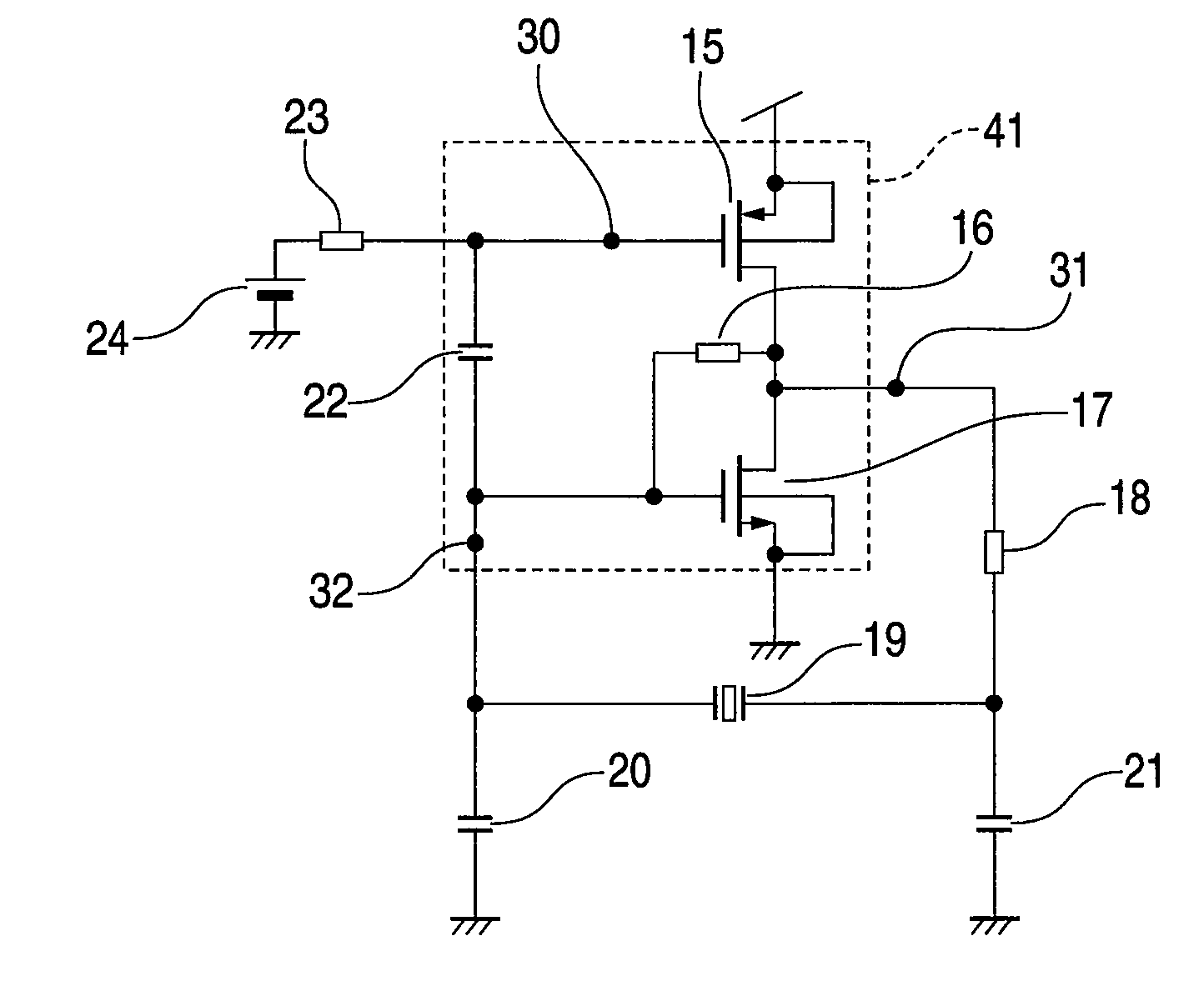

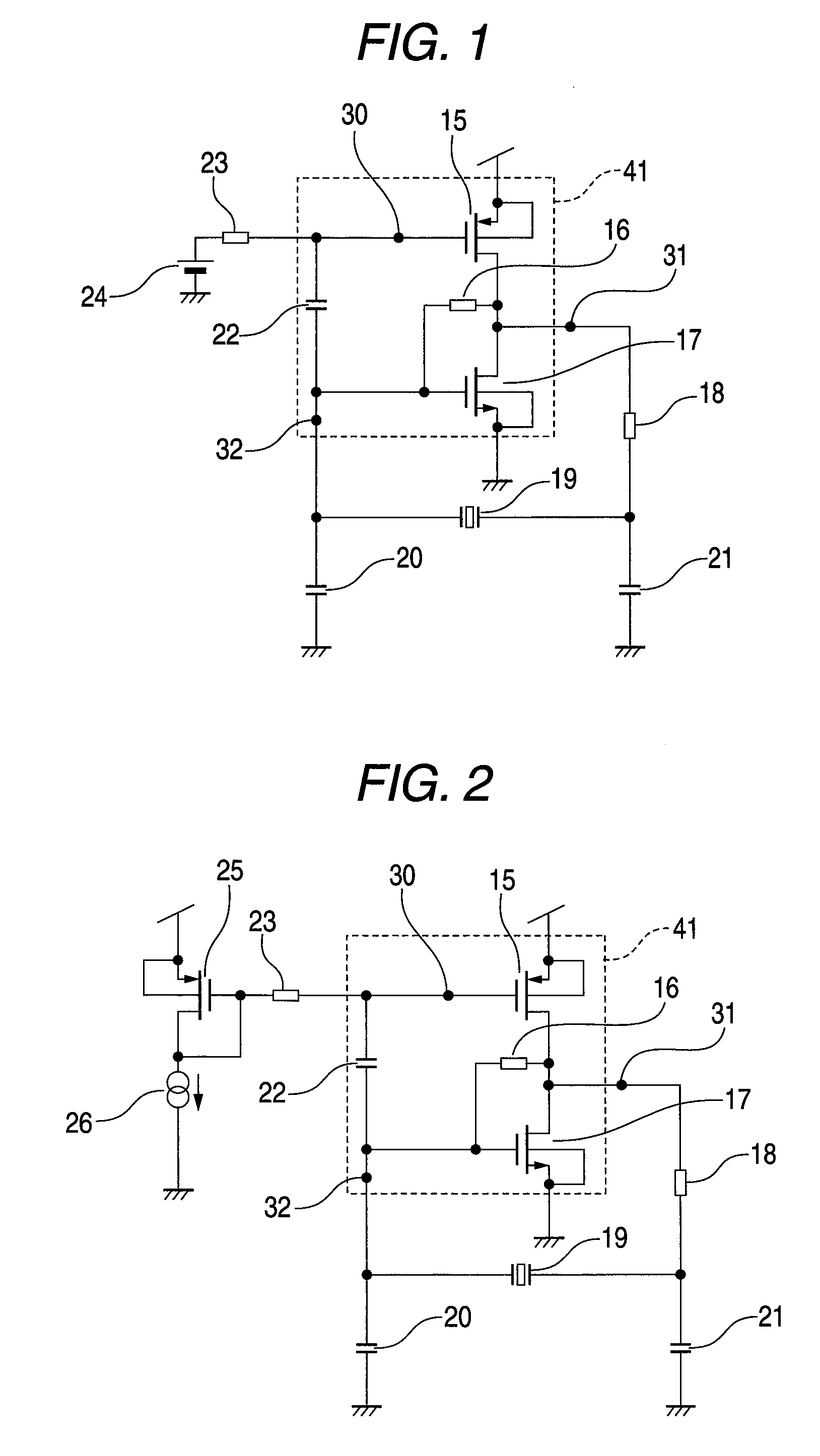

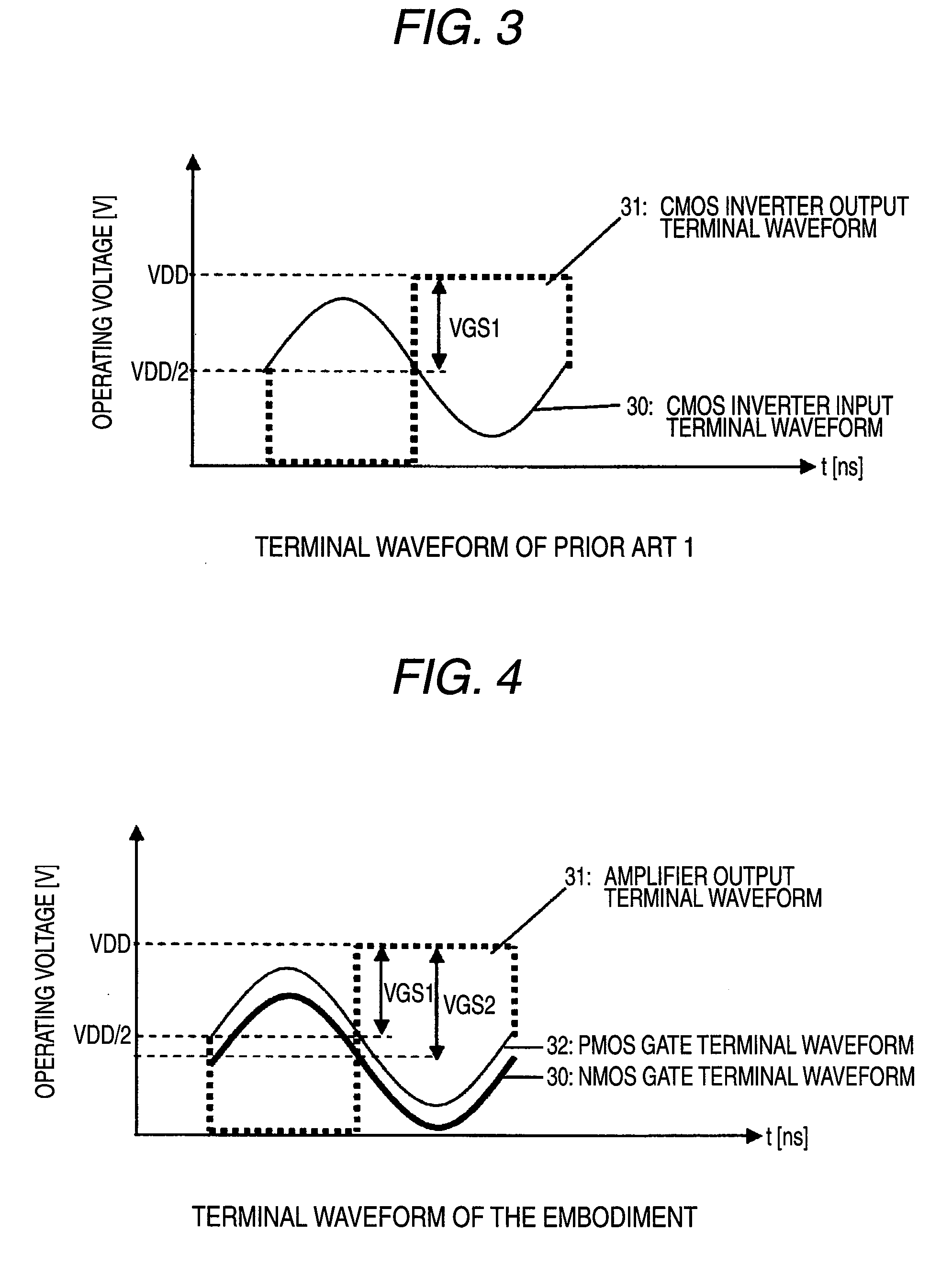

Piezoelectric oscillator

InactiveUS20080238561A1Increase negative resistanceSatisfactory negative resistanceApparatus using electrochemical resonatorsElectric pulse generatorAudio power amplifierEngineering

For a piezoelectric oscillator according to the present invention, an oscillator circuit includes: a piezoelectric vibrator; an NMOS transistor and a PMOS transistor that constitute an amplifier connected in parallel to the piezoelectric vibrator; and load capacitors connected in parallel to the piezoelectric vibrator. The gate terminals of the NMOS transistor and the PMOS transistor, which are constituents of the amplifier, are connected by a DC cut capacitor, and the gate terminal of the NMOS transistor and the output terminal of the amplifier are connected by a feedback resistor. An arbitrary bias voltage, to be applied to the gate terminal of the PMOS transistor via a high-frequency elimination resistor, is generated by a circuit provided by a diode-connected, second PMOS transistor.

Owner:PANASONIC CORP

Ink jet recording ink, ink jet recording ink set, recording method, recorded matter and ink jet recording apparatus

InactiveUS20080146713A1Excellent long-term storage stabilityHigh print densityMeasurement apparatus componentsInksDispersion stabilityAlcohol

Provided are an ink jet recording ink (IJ ink), an ink jet recording ink set (IJ ink set) and a recording method, having excellent dispersion stability and ejection stability and being capable of providing images which is free from bleeding and which is excellent in color development property and rubbing resistance. An IJ ink and I an IJ ink set having long-term storage stability are provided. Also provided are recorded matter having excellent color development property and rubbing resistance, and an ink jet recording apparatus capable of providing the same. The invention includes: an IJ ink containing a colorant of a pigment and / or dye enveloped in a polymer, and water, and containing at least one compound selected from the group consisting: of acetylene glycol surfactants, acetylene alcohol surfactants, glycol ethers and 1,2-alkylene glycols; an IJ ink set comprising a plurality of the inks; a recording method of using the ink and / or the ink set; recorded matter printed according to the recording method; and an ink jet recording apparatus having an electrostrictive unit mounted thereon and is designed so as to be capable of ejecting the ink.

Owner:SEIKO EPSON CORP

Member used for casting

ActiveUS20060032602A1Improve mold lifeProlong lifeVacuum evaporation coatingFoundry mouldsNitrideHigh-speed steel

A casting member comprising hot-die steel or high-speed steel as base material and having coating layers at least on its working plane, wherein the outermost layer among the coating layers consists essentially of at least one nitride, oxinitride or carnonitride composed mainly of V, and another coating layer comprising at least one nitride, oxinitride or carnonitride composed mainly of Cr is formed as a layer just above the base material. If necessary, an intermediate layer comprising at least one nitride, oxinitride or carnonitride composed mainly of V and Cr may be formed as a coating layer on the boundary surface between the outermost layer and the layer just above the base material. The thickness of the outermost layer is preferably 0.5 to 5.0 μm, the thickness of the layer just above the base material is preferably 0.5 to 3.0 μm, and the thickness of the intermediate layer is preferably 1.0 μm or less. Said casting member has excellent resistance to seizure, resistance to cracking and resistance to waste by melting.

Owner:HITACHI METALS LTD

Laminating adhesive, laminate using the same, and secondary battery

InactiveUS20170088753A1Improve adhesionSatisfactory durabilityNon-macromolecular adhesive additivesCell electrodesPolyolefinAdditive ingredient

It is an object to provide a novel laminating adhesive to thereby allow provision of a laminating adhesive composition for a laminate that provides good adhesion between a metal layer and a plastic layer, has satisfactory moisture barrier properties, heat resistance, insulation properties, durability, etc., also exhibits electrolyte resistance even after low-temperature curing, and does not undergo delamination over time. A laminate that uses the laminating adhesive composition and a secondary battery are also provided. The object is achieved by a laminating adhesive containing a non-chlorine-based polyolefin resin (A), an epoxy compound (B), and an organic solvent (C) including a cyclic alkane compound as an essential ingredient and further including an ester-based solvent or an alcohol-based solvent. In the organic solvent (C), the ratio, in parts by mass, of the cyclic alkane compound to the solvent other than the cyclic alkane compound is within the range of 1 / 1 to 20 / 1.

Owner:DAINIPPON INK & CHEM INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com