Water-based inorganic resin and preparation method thereof

An inorganic resin, water-based technology, used in anti-corrosion coatings, alkali metal silicate coatings, coatings, etc., can solve the problems of poor water resistance of paint film, high cost of lithium silicate, insoluble in water, etc., to improve hardness, Excellent salt spray resistance and long-term corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

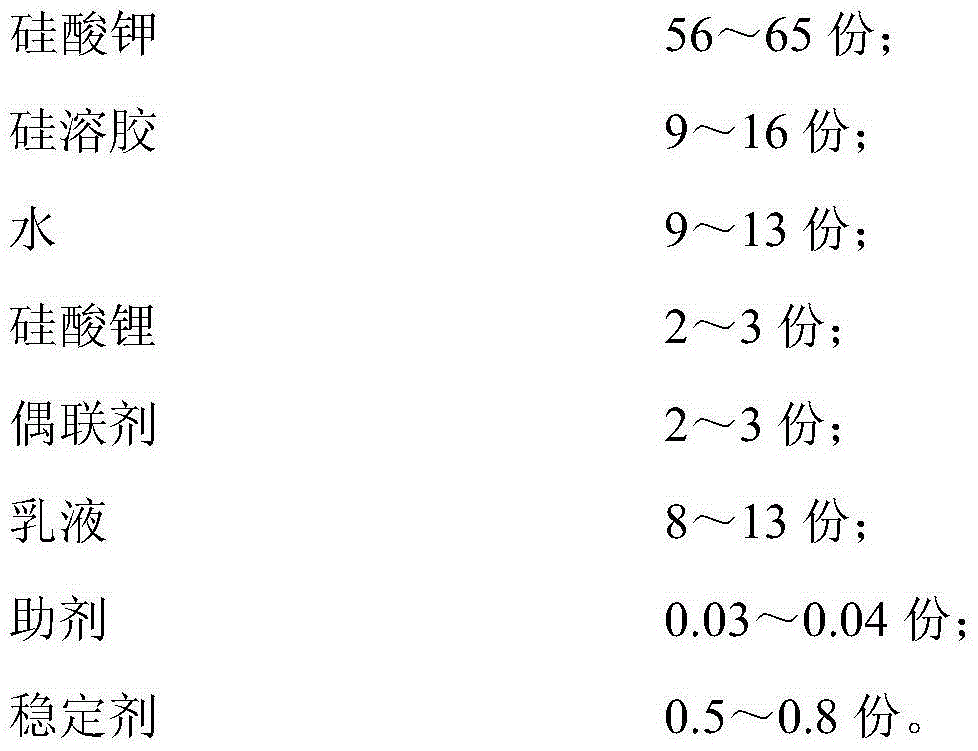

[0021] (1) Resin formula (by weight):

[0022]

[0023] (2) Preparation method:

[0024] Reserve 5.0wt% of the formula amount of deionized water for use, and add the rest of the deionized water into the dispersion kettle, start stirring at 600-800r / min, add potassium silicate, silica sol, and lithium silicate in the formula amount, and continue stirring ;Continue to stir for 5 minutes after the addition, then slowly add the coupling agent in the formula dropwise, drop it within 15-20 minutes, reduce the stirring speed, keep stirring at 400-500r / min for 2 hours, stop the machine, and stand still for 24 hours Above, under the condition of 400-500r / min, slowly add the emulsion in the formula, the reserved 5wt% deionized water and the additives and stabilizers in the formula, and keep stirring for 1 hour, and use a 150-mesh silk filter cloth Filtration, sampling and testing, packaging.

Embodiment 2

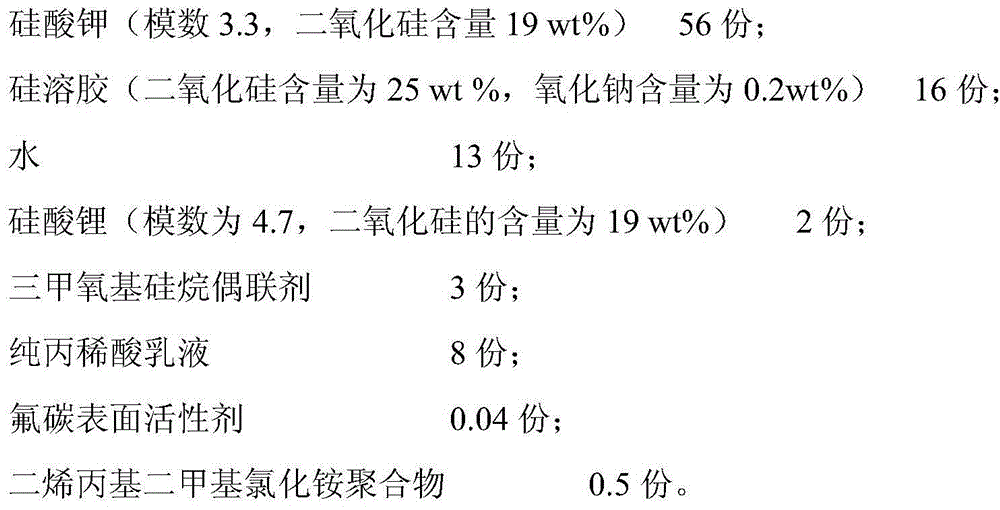

[0026] (1) Resin formula (by weight):

[0027]

[0028] (2) Preparation method:

[0029] Reserve 5.0wt% of the formula amount of deionized water for use, and add the rest of the deionized water into the dispersion kettle, start stirring at 600-800r / min, add potassium silicate, silica sol, and lithium silicate in the formula amount, and continue stirring ;Continue to stir for 5 minutes after the addition, then slowly add the coupling agent in the formula dropwise, drop it within 15-20 minutes, reduce the stirring speed, keep stirring at 400-500r / min for 2 hours, stop the machine, and stand still for 24 hours Above, under the condition of 400-500r / min, slowly add the emulsion in the formula, the reserved 5wt% deionized water and the additives and stabilizers in the formula, and keep stirring for 1 hour, and use a 150-mesh silk filter cloth Filtration, sampling and testing, packaging.

Embodiment 3

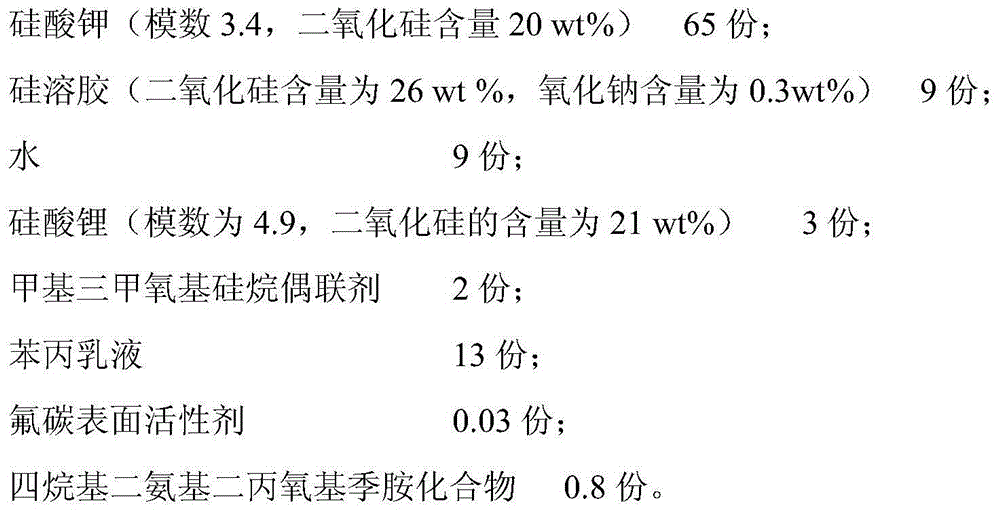

[0031] (1) Resin formula (by weight):

[0032]

[0033] (2) Preparation method:

[0034] Reserve 5.0wt% of the formula amount of deionized water for use, and add the rest of the deionized water into the dispersion kettle, start stirring at 600-800r / min, add potassium silicate, silica sol, and lithium silicate in the formula amount, and continue stirring ;Continue to stir for 5 minutes after the addition, then slowly add the coupling agent in the formula dropwise, drop it within 15-20 minutes, reduce the stirring speed, keep stirring at 400-500r / min for 2 hours, stop the machine, and stand still for 24 hours Above, under the condition of 400-500r / min, slowly add the emulsion in the formula, the reserved 5wt% deionized water and the additives and stabilizers in the formula, and keep stirring for 1 hour, and use a 150-mesh silk filter cloth Filtration, sampling and testing, packaging.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Modulus | aaaaa | aaaaa |

| Proportion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com