Matt polyester film preparation method

A technology of polyester film and matt, which is applied in the field of preparation of matt polyester film, which can solve problems such as difficulty in uniform dispersion, difficulty in uniform dispersion of additives, uneven dispersion of additives, etc., and achieve a good matt effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

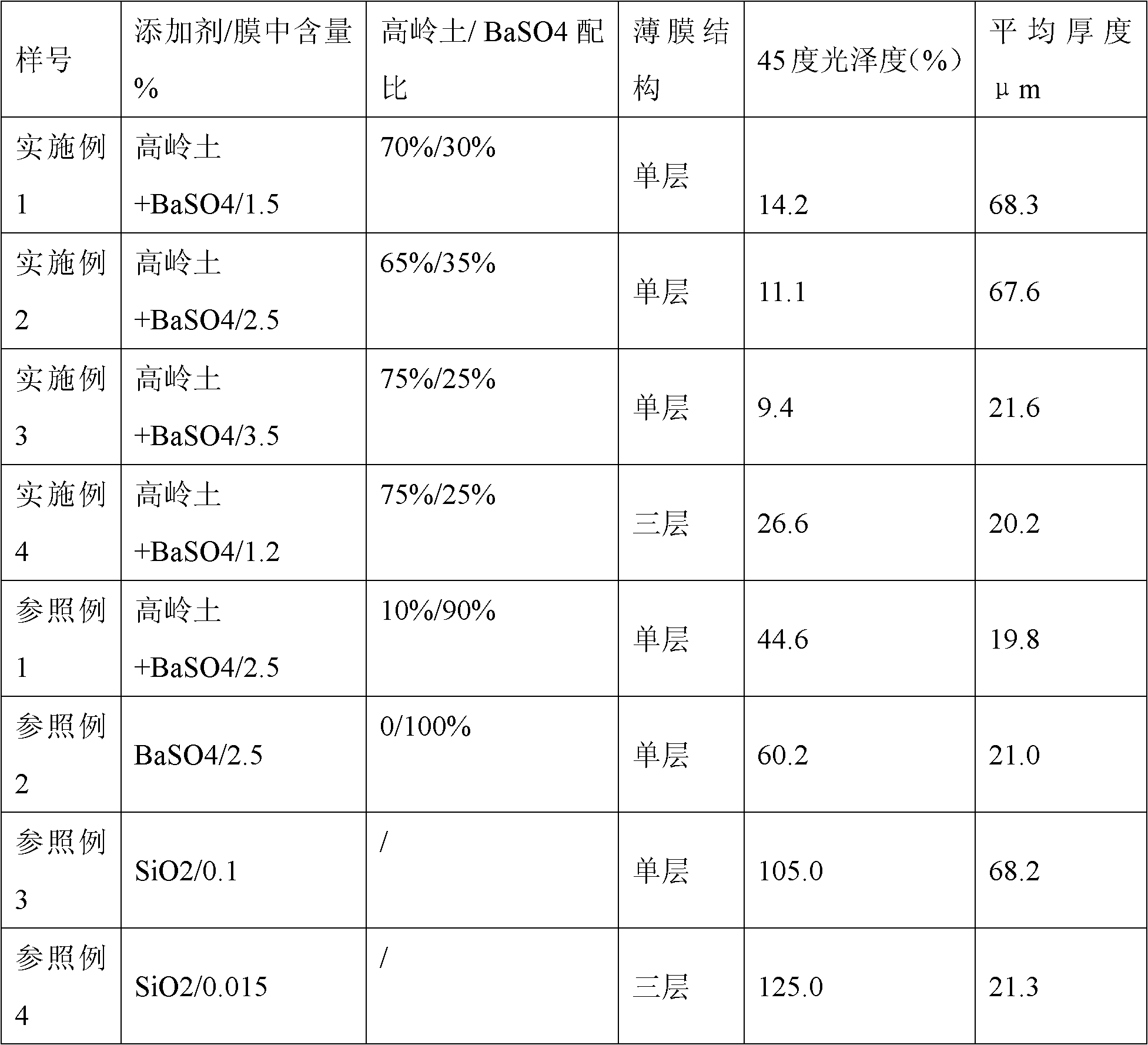

Examples

Embodiment 1

[0020] Add 400ml glass beads, 140g kaolin, 60g barium sulfate, 600g ethylene glycol, 0.3g sodium polyphosphate into a sand mill and grind for 1 hour to prepare kaolin-barium sulfate-ethylene glycol suspension, wherein kaolin-barium sulfate The average particle size is 0.32 μm.

[0021] Add 5.0Kg PTA, 3KgEG, 2.0g antimony acetate, 278g of the above-mentioned kaolin-barium sulfate-ethylene glycol suspension into a 20L general-purpose polymerization reactor, and carry out esterification at 230-265°C and 0.2-0.3Mpa (gauge pressure) Reaction, when the water output reaches 1200ml, release the pressure to normal pressure, add 1.025g of triphenyl phosphate, stir at normal pressure for 10 minutes, raise the temperature and lower the pressure to 280°C and below 100Pa, and react for 1 to 3 hours. After the reaction is completed, it is extruded by a melt pump, pelletized, and dried to obtain a matt polyester film slice with an intrinsic viscosity of 0.650 dl / g.

[0022] Pre-crystallize, ...

Embodiment 2

[0024] Add 400ml glass beads, 182g kaolin, 98g barium sulfate, 520g ethylene glycol, 0.7g potassium polyphosphate into a sand mill, and grind for 1.5 hours to prepare a kaolin-barium sulfate-ethylene glycol suspension, wherein kaolin-barium sulfate The average particle size is 0.36 μm.

[0025] Add 5.0kg of PTA, 3.0kg of EG, 0.93g of germanium dioxide, 413g of the above-mentioned kaolin-barium sulfate-ethylene glycol suspension into a 20L general-purpose polymerization reactor, and perform esterification at 230-265°C and 0.2-0.3Mpa (gauge pressure). Chemical reaction, when the water output reaches 1200ml, release the pressure to normal pressure, add 0.44g trimethyl phosphate, stir at normal pressure for 10 minutes, raise the temperature and lower the pressure to 280°C and below 100Pa, and react for 1 to 3 hours. After the reaction is completed, it is extruded by a melt pump, pelletized, and dried to obtain polyester chips for a matte film with an intrinsic viscosity of 0.610 d...

Embodiment 3

[0028] Add 400ml of glass beads, 300g of kaolin, 100g of barium sulfate, 400g of ethylene glycol, and 1.4g of potassium polyphosphate into a sand mill, and grind for 1.5 hours to prepare a suspension of kaolin-barium sulfate-ethylene glycol, in which kaolin-barium sulfate The average particle size is 0.39 μm.

[0029]Add 5.0kg of PTA, 3.0kg of EG, 1.71g of ethylene glycol antimony, 402g of the above-mentioned kaolin-barium sulfate-ethylene glycol suspension into a 20L general-purpose polymerization reactor, and conduct the polymerization at 230-265°C and 0.2-0.3Mpa (gauge pressure). For esterification reaction, when the water output reaches 1200ml, release the pressure to normal pressure, add 0.84g triethyl phosphate, stir for 10 minutes under normal pressure, raise the temperature and lower the pressure to 280°C and below 100Pa, and react for 1 to 3 hours. After the reaction is completed, it is extruded by a melt pump, pelletized, and dried to obtain polyester chips for matt ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com