Modified polyvinyl chloride cable material and preparation method thereof

A technology of polyvinyl chloride cable and polyvinyl chloride resin, which is applied to plastic/resin/wax insulators, organic insulators, etc., can solve the problems such as the lack of matte matte on the rubber surface, unfavorable extrusion molding, complicated process, etc. Achieve the effect of improving mechanical physical and chemical properties, good matte effect, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

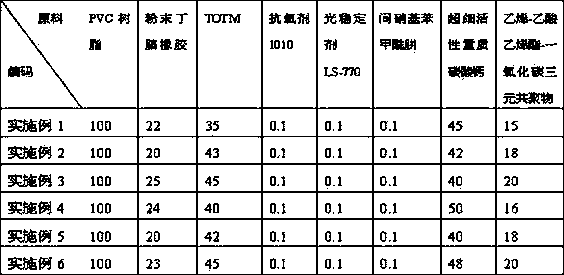

[0019] Prepare materials under the implementation of 1-6 items in Table 1, and operate as follows:

[0020] In the kneader, add each raw material component, control the temperature at 90~100°C, stir evenly, send it into the extruder, control the temperature at 140~170°C, plasticize and extrude, granulate, and make a modified PVC cable Materials products, packaging.

[0021] Table 1 Example raw material formula (unit: kg)

[0022]

[0023] The modified polyvinyl chloride cable material sample of the present invention is tested according to the requirements of H-70 in the GB / T 8815-2008 standard, and the test results are shown in the following table:

[0024] .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com