Ultraviolet ray-curable low-gloss flow-coating paint and preparation method thereof

A UV light, low gloss technology, used in polyester coatings, epoxy resin coatings, coatings, etc., can solve the problems of jelly-like phenomenon of coatings, inability to carry out construction, fluidity problems, etc., to achieve good matte effect, The effect of good liquidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

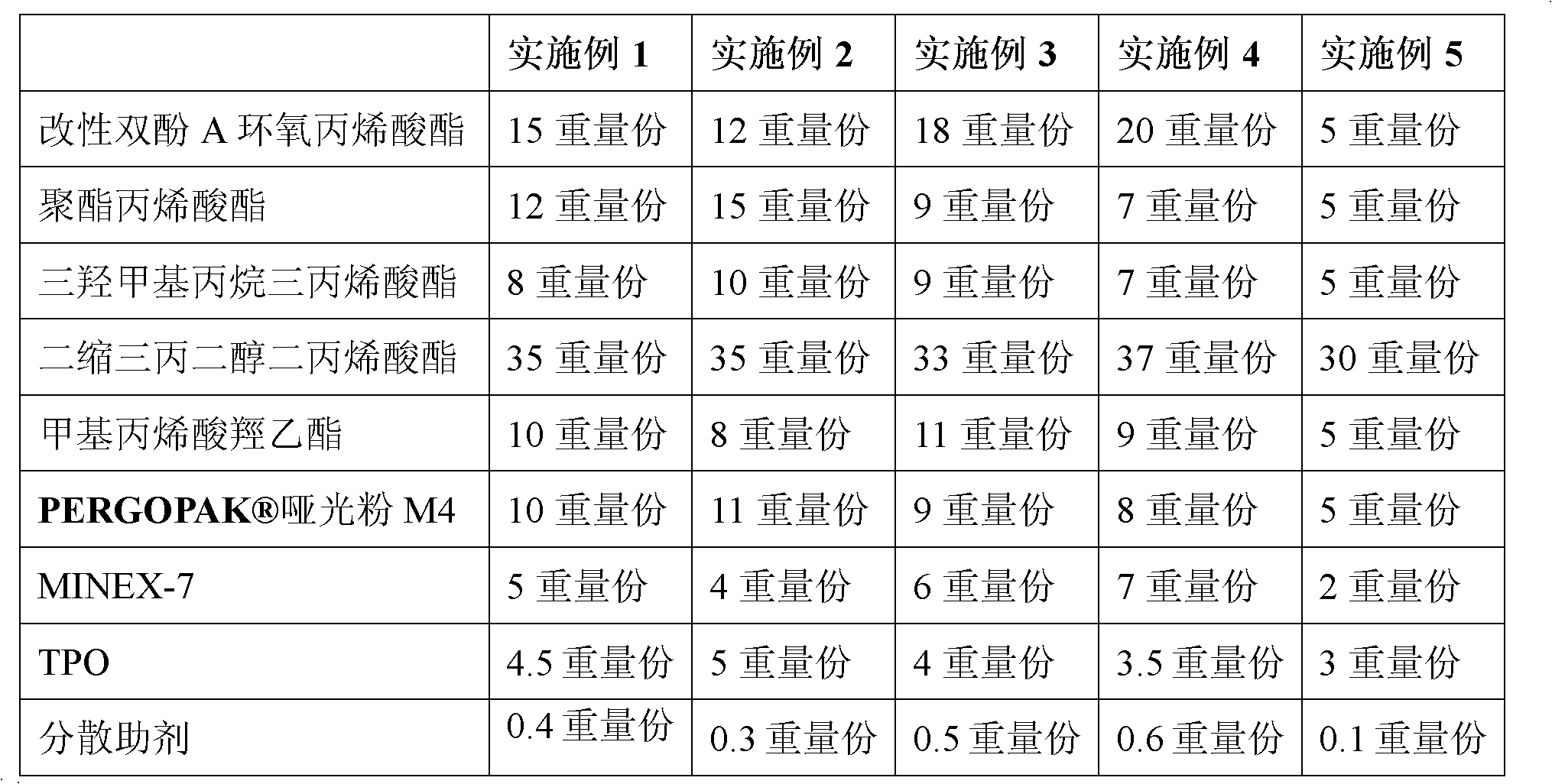

Embodiment 1~5

[0042]

[0043] In the above table, the modified bisphenol A epoxy acrylate in Example 1 is F09 from Jiangsu Litian Technology Co., Ltd., the polyester acrylate is 5010F from Corning Chemical (China) Co., Ltd., and trimethylolpropane Acrylate, tripropylene glycol diacrylate, and hydroxyethyl methacrylate were purchased from Jiangsu Litian Technology Co., Ltd., the dispersing aid was 4010F from Efka Company, and MINEX-7 was purchased from Shenzhen Wenova Chemical Materials Co., Ltd.

Embodiment 2

[0044] The modified bisphenol A epoxy acrylate in Example 2 was SM-6109 from Jiangsu Sanmu Chemical Company, the polyester acrylate was 6360 from Changxing Chemical Industry Co., Ltd., trimethylolpropane triacrylate, dimethicone Propylene glycol diacrylate and hydroxyethyl methacrylate were purchased from Jiangsu Sanmu Chemical Company, and MINEX-7 was purchased from Shenzhen Winova Chemical Materials Co., Ltd.

Embodiment 3

[0045] The modified bisphenol A epoxy acrylate in Example 3 is Zhongshan Ketian Electronic Materials Co., Ltd. 4232, the polyester acrylate is Changxing Chemical Industry Co., Ltd. 6360, trimethylolpropane triacrylate, dimethicone Propylene glycol diacrylate and hydroxyethyl methacrylate were purchased from Tianjin Tianjiao Chemical Co., Ltd., and MINEX-7 was purchased from Shenzhen Winova Chemical Materials Co., Ltd.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com