IMR (in-mold decoration by roller) matte ink and preparation and application methods thereof

A matte ink and matte material technology, applied in the field of ink, can solve the problem that the printing surface cannot achieve matte effect, etc., and achieve the effect of good effect stability, high yield and uniform coating.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The embodiment of the present invention also provides a preparation method of IMR matte ink, which includes the following steps: first dissolve the resin with a solvent, then add additives, fillers, and matting materials for mixing treatment, and finally filter the mixed solution obtained from the mixing treatment .

[0038] The method for preparing IMR matte ink provided by the invention has the advantages of simple process, low cost and small occupied space, and the ink directly obtained by the method can achieve the matte effect of IMR printing surface.

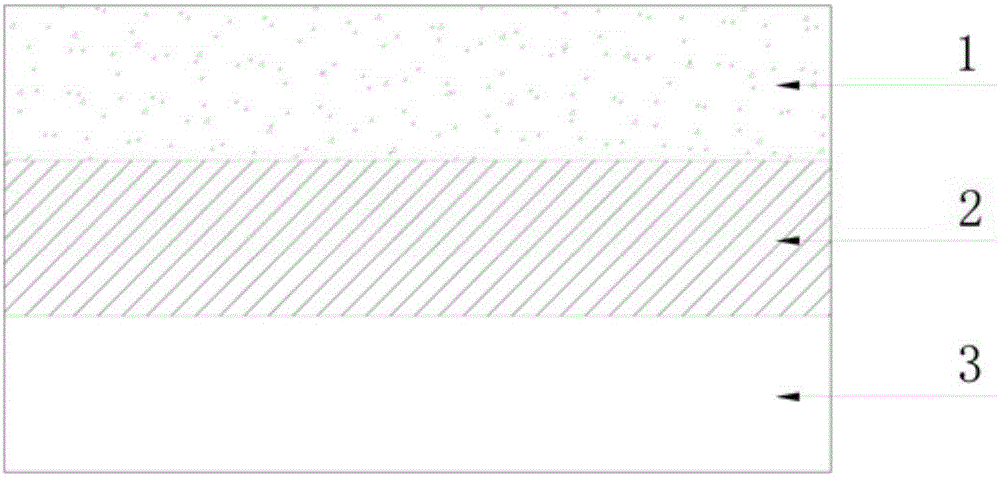

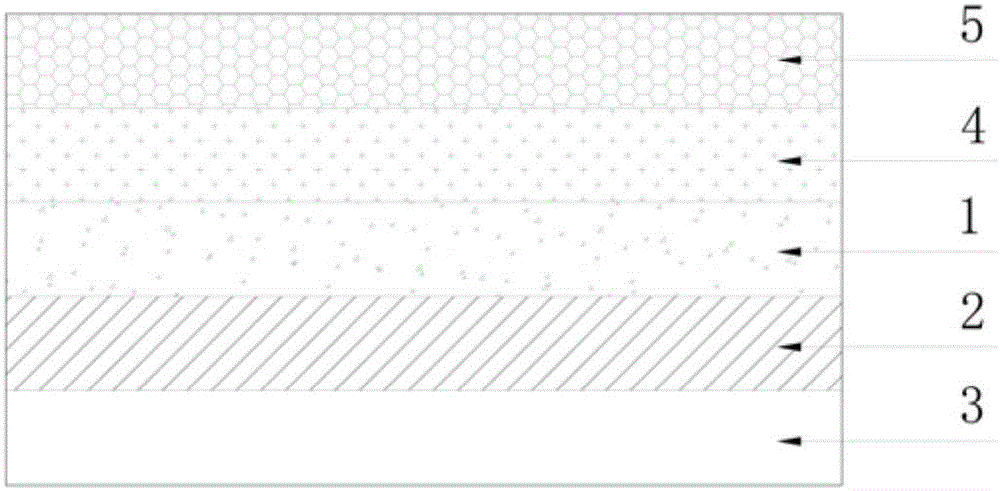

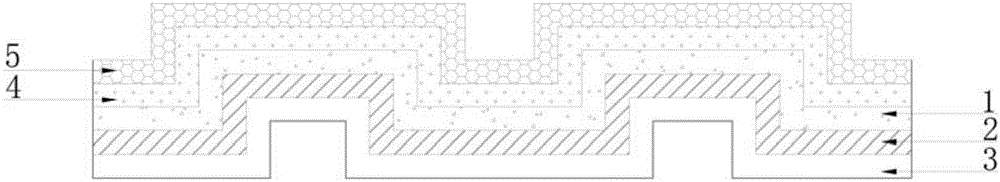

[0039] The embodiment of the present invention also provides a method for using IMR matte ink, which includes the following steps: printing the matte ink on the surface of the sheet, and covering it with PE film after drying; then drying, plastic molding; assembling into a mold for injection molding; mold, remove the PE film.

[0040] Specifically, the drying process of the method for using the IMR matte ink is: ba...

Embodiment 1

[0045] Present embodiment provides a kind of matte ink of molding PC helmet, and it has following components:

[0046]

[0047] The preparation process of the matte ink in this embodiment is as follows: dissolve A21 (thermoplastic acrylic resin) with cyclohexanone, add diacetone alcohol, tego910, BYK-333 after it is completely dissolved, and add the matting material while stirring, and wait until it is uniformly dispersed Filter to get finished ink.

Embodiment 2

[0049] Present embodiment provides a kind of matte ink of molding PC helmet, and it has following components:

[0050]

[0051] The preparation process of the matte ink in this embodiment is as follows: dissolve A21 (thermoplastic acrylic resin) with cyclohexanone, add diacetone alcohol, tego910, BYK-333 after it is completely dissolved, and add the matting material while stirring, and wait until it is uniformly dispersed Filter to get finished ink.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com