Novel water-based low-gloss ultraviolet-curable paint and preparation and application methods thereof

A technology of curing coatings and ultraviolet light, applied in polyether coatings, polyurea/polyurethane coatings, coatings, etc., can solve problems such as strong residual odor, easy paint removal, and water resistance, and achieve good safety protection performance and high improvement. Oil-absorbing and fluidity-promoting effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

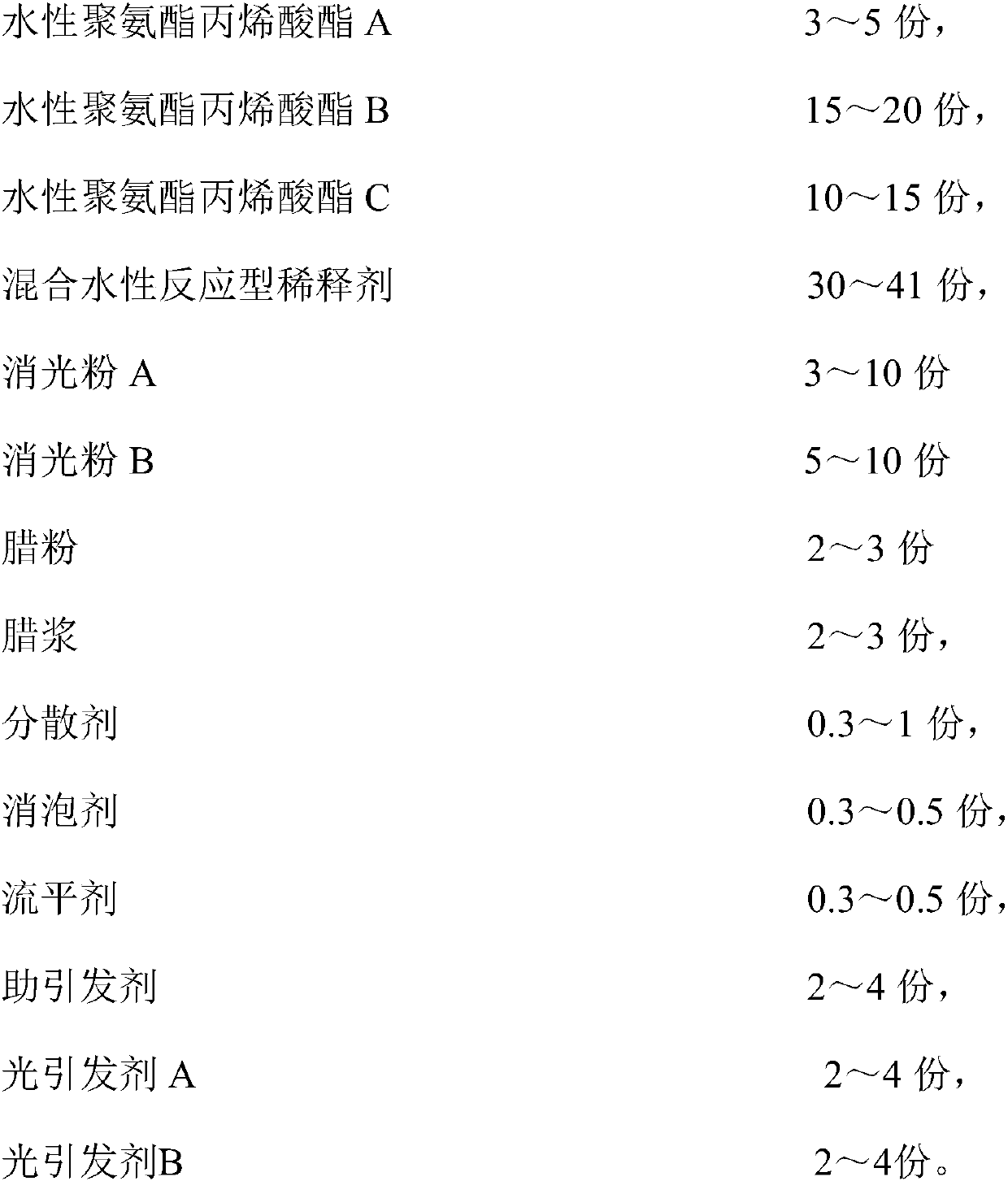

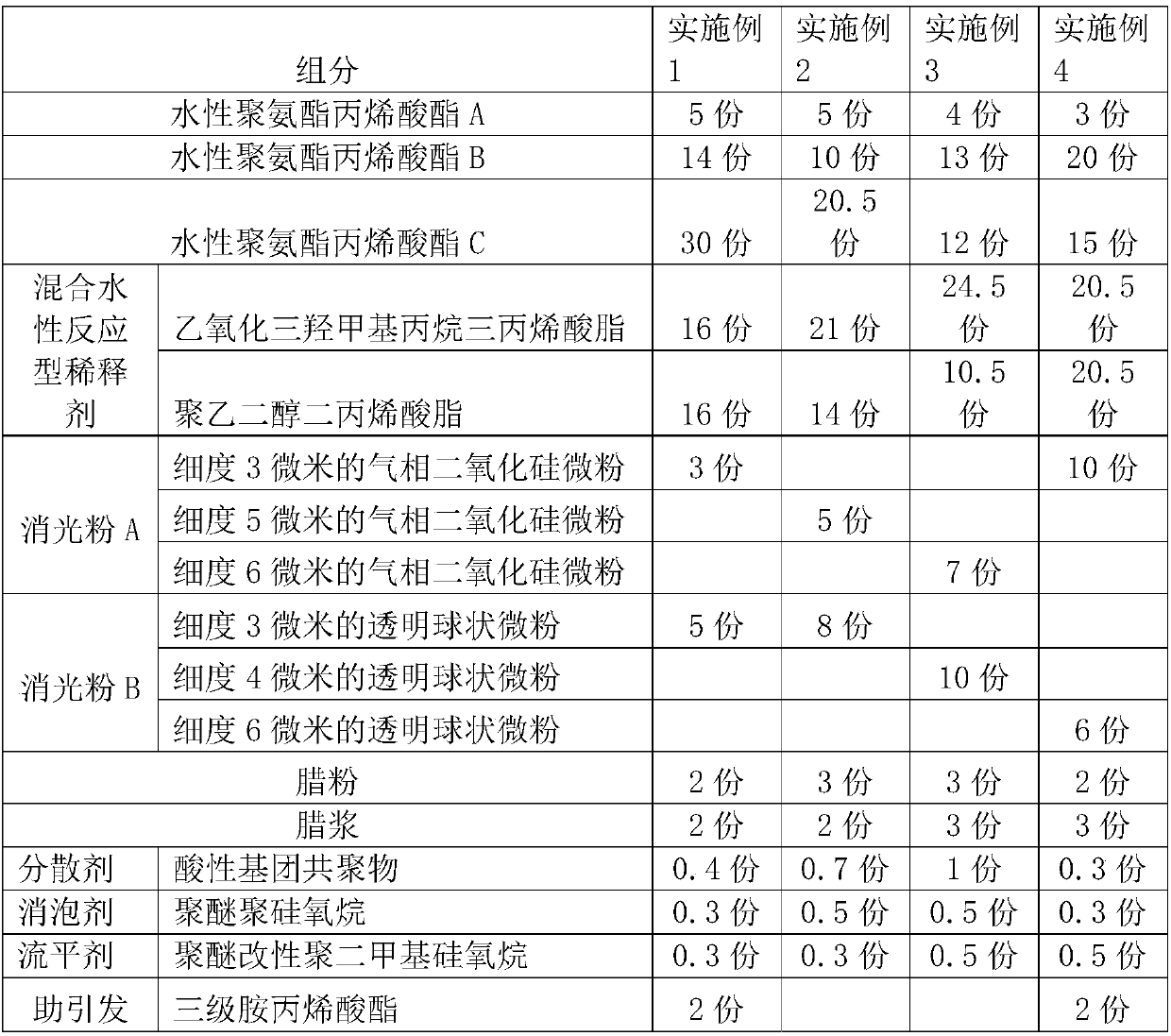

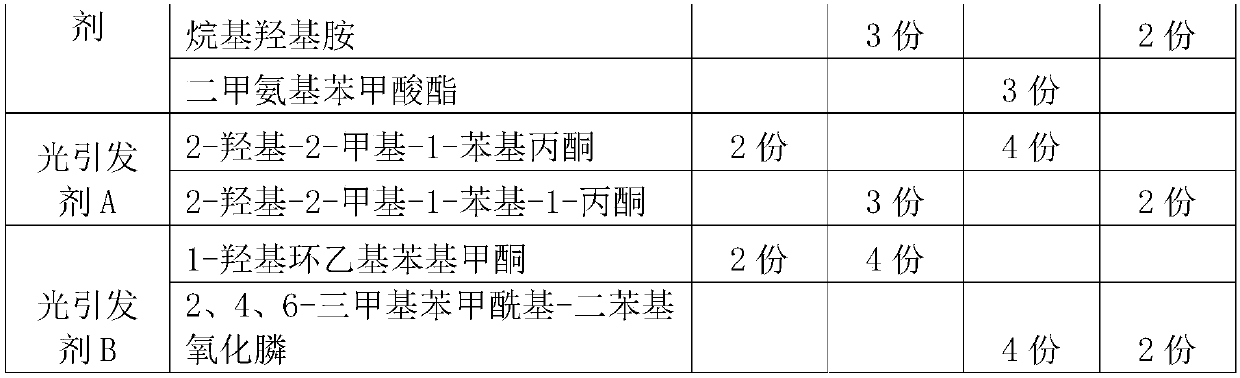

[0024] The novel water-based low-gloss UV-curable coating of the present invention and its preparation method will be further described below in conjunction with specific examples 1-4.

[0025] A preparation method for a novel water-based low-gloss UV-curable coating comprises the following steps:

[0026] 1) Mix the anti-water-based diluent, dispersant, defoamer, leveling agent, matting powder A, matting powder B, photoinitiator A, photoinitiator B, and co-initiator at a speed of 300 to 450 rpm Add and mix in turn under stirring at 1 / min, and then stir at 700-900 rpm for 15-25 minutes to obtain the initial stage mixture;

[0027] 2) Add water-based urethane acrylates A, B, and C to the above-mentioned mixture in the initial stage in sequence, and then stir at a speed of 700-900 rpm for 15-25 minutes. After filtering to remove impurities, a new type of water-based low-gloss UV curing is obtained. coating.

[0028] Table 1: The distribution ratios of each group in Embodiment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com